In-system programming universal PFC multifunctional processor

A processor and multi-functional technology, applied in the fields of instruments, climate sustainability, output power conversion devices, etc., can solve the problems of poor versatility of PFC modules, and achieve the effect of reducing sampling points, simple processing, and reducing EMI

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

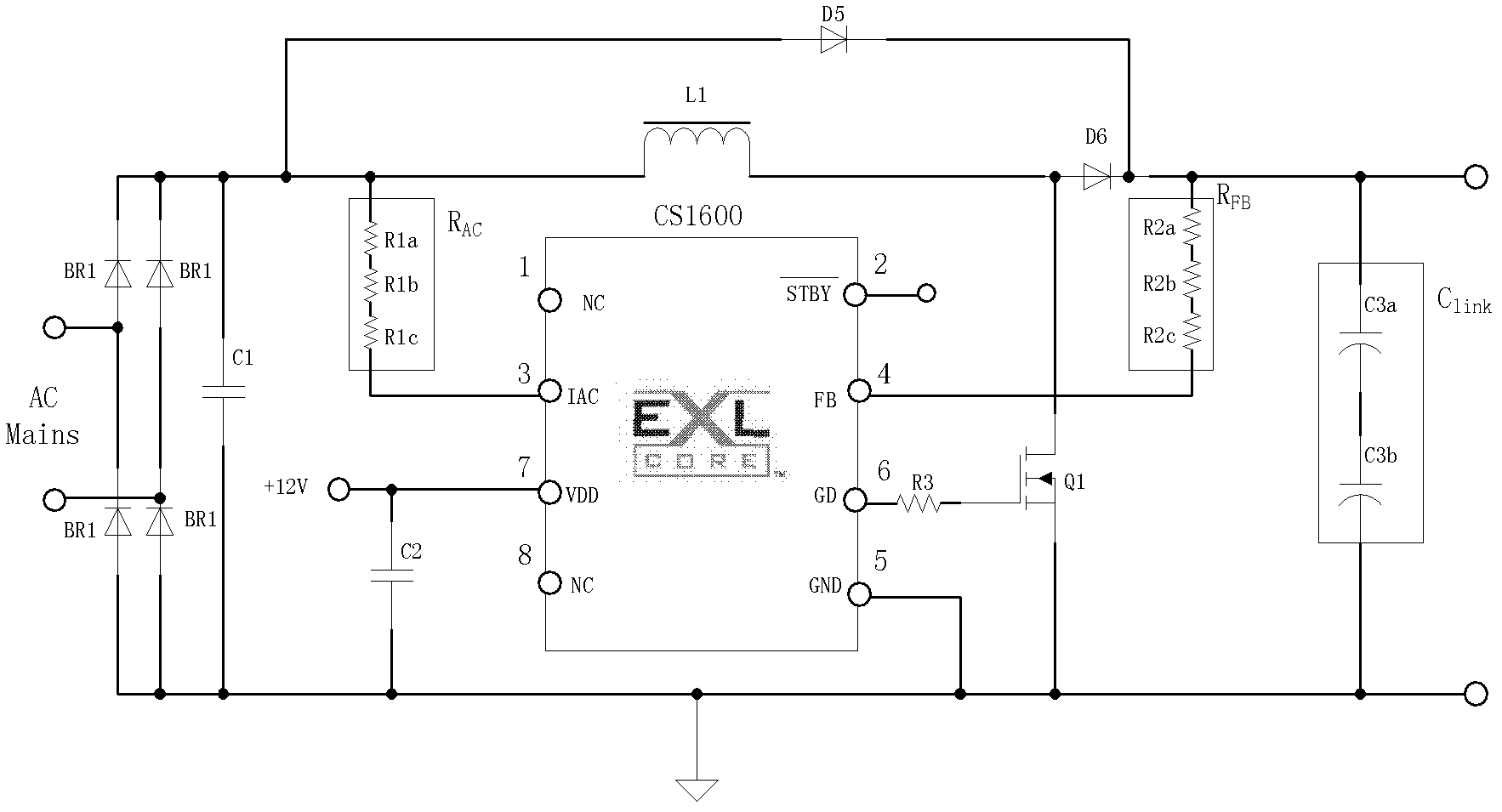

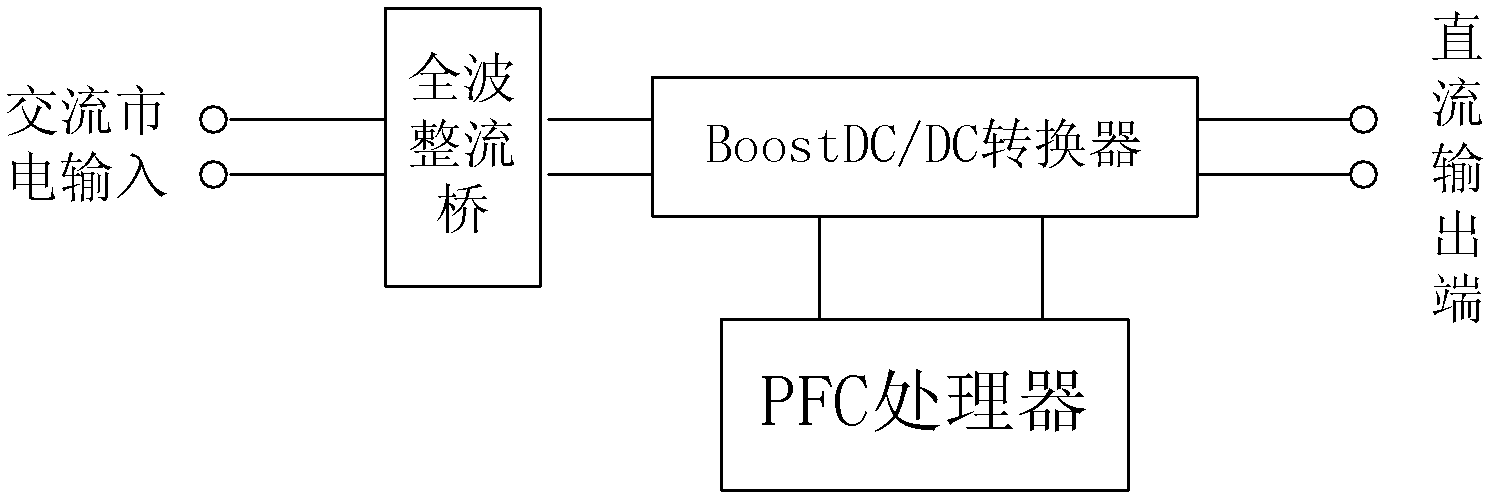

[0036] see Figure 5 According to the conception of this case and the first example realized based on the BOOST step-up converter, it mainly includes mains input, full-wave rectifier bridge BD, inductor L1, inductor current sampling circuit, power switch tube Q1, steering diode D1, capacitor C1 , Output voltage sampling circuit, load resistor R and PFC processor. The live line L of the mains is connected to the AC input terminal AC+ of the rectifier bridge BD; the neutral line N of the mains is connected to the AC- terminal of the rectifier circuit; one end of the inductor L1 is connected to the DC input end DC+ of the rectifier bridge BD, and the other end is connected to the power The drain of the switching tube Q1 and the anode of the steering diode D1; the source of the switching tube Q1 is connected to one end of the current sampling resistor R1, and the gate of the switching tube is connected to the port I / O.0 of the main control microcontroller; the other end of the cur...

no. 2 example

[0040] see Figure 6 According to the concept of this case and based on the BUCK step-down converter, the second example mainly includes mains input, full-wave rectifier bridge BD, power switch tube Q1, diversion diode D1, inductor L1, capacitor C1, load resistor R, Output voltage sampling circuit, inductor current sampling circuit and PFC processor. The live line L of the mains is connected to the AC input terminal AC+ of the rectifier bridge BD; the neutral line N of the mains is connected to the AC- terminal of the rectification circuit; The cathode of the diode D is connected to one end of the inductor L1, and the gate is connected to the port I / O.0 of the main control microcontroller; the anode of the diode D is connected to the current sampling resistor R1; the other end of the current sampling resistor R1 is connected to the rectifier bridge BD The DC-end is connected; the other end of the inductor L1 is connected to the capacitor C1, one end of the resistor R2a, and o...

no. 3 example

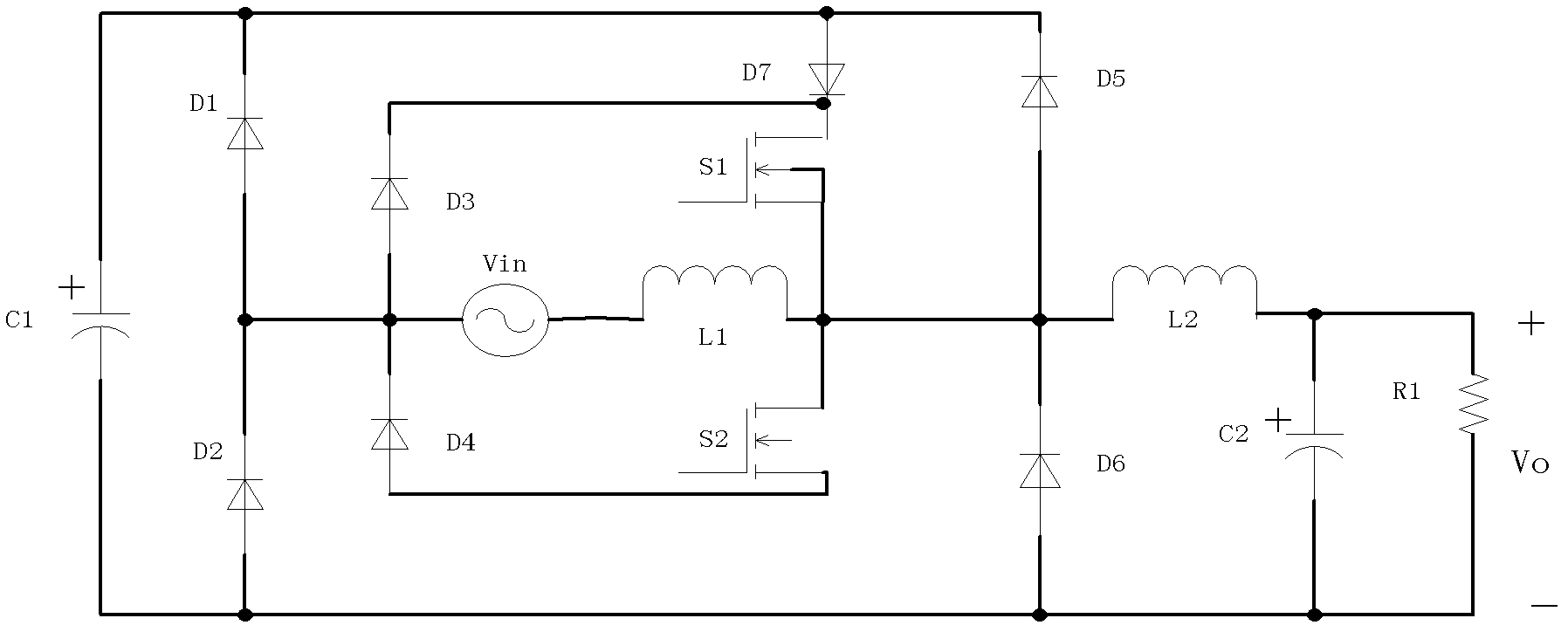

[0044] see Figure 7 According to the concept of this case and based on the BOOST / BUCK buck-boost converter, the third example mainly includes mains power, full-wave rectifier bridge BD, power switch tube Q1, inductor L1, steering diode D1, capacitor C1, output voltage Sampling circuit, LED load, inductor current sampling circuit and PFC processor. The live line L of the mains is connected to the AC input terminal AC+ of the rectifier bridge BD; the neutral line N of the mains is connected to the AC- terminal of the rectification circuit; The cathode of the diode D is connected to one end of the inductor L1, and the gate is connected to the port I / O.0 of the main control microcontroller; the other end of the inductor L1 is connected to one end of the current sampling resistor R1; the other end of the sampling resistor R1 is connected to the rectifier The DC-end of the bridge BD is connected; the anode of the reverse flow diode D is connected to one end of the capacitor C1, on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com