Special equipment for bending power wire

A special equipment and power technology, applied in the field of special equipment in the power industry, can solve the problems of inability to fix aluminum cables, copper cables, difficult to ensure uniform wire shape, slow bending speed, etc., to avoid damage to the cable, easy to manufacture , the effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

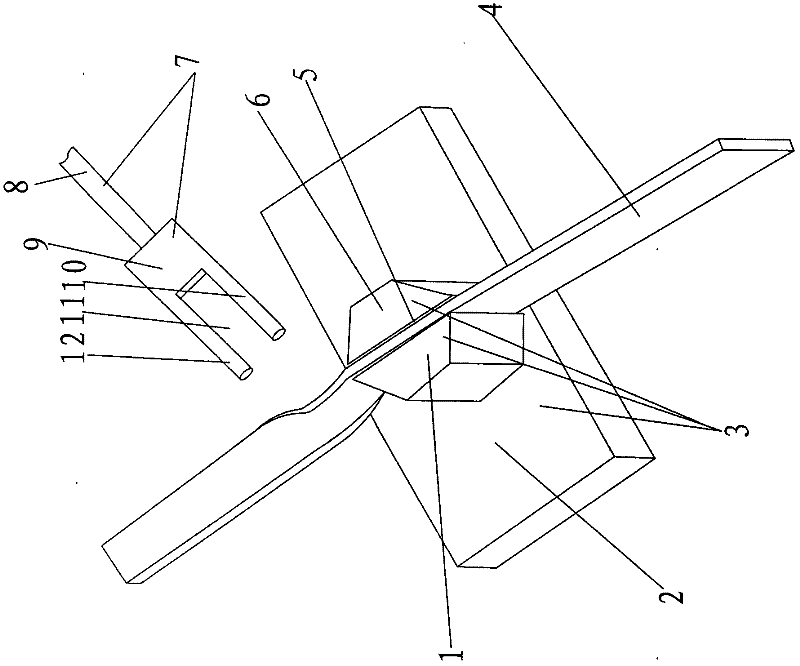

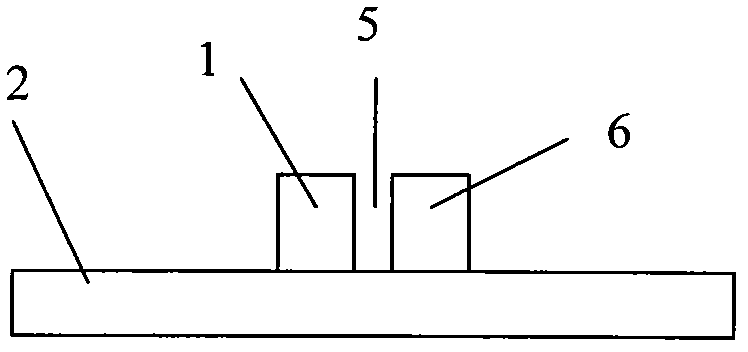

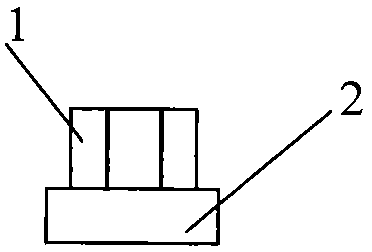

[0011] Such as figure 1 Shown, the present invention is made up of wrench 7 and holder 3, as figure 1 , 2 , 3, and 4, the fixed seat 3 is made up of base 2, left block 1, and right block 6, and the materials of the three can be cast iron or steel, and the left block 1 and the right block 6 are welded to the base 2 are connected into one body, and a gap is reserved between the left block 1 and the right block 6 to form a line positioning groove 5. This gap is the line positioning slot 5 for positioning the line sideways, and is used for connecting with the aluminum row. Or the thickness of the copper row is adapted, and the width of the cable positioning slot 5 is 10-12 mm. According to the specific thickness of the cable, various specifications of the fixing seat 3 can be produced.

[0012] Such as figure 1 , Figure 5 , Image 6 As shown, the wrench 7 of the present invention is partly welded by the wrench head 9 and the grip rod 8, and the wrench head 9 is provided wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com