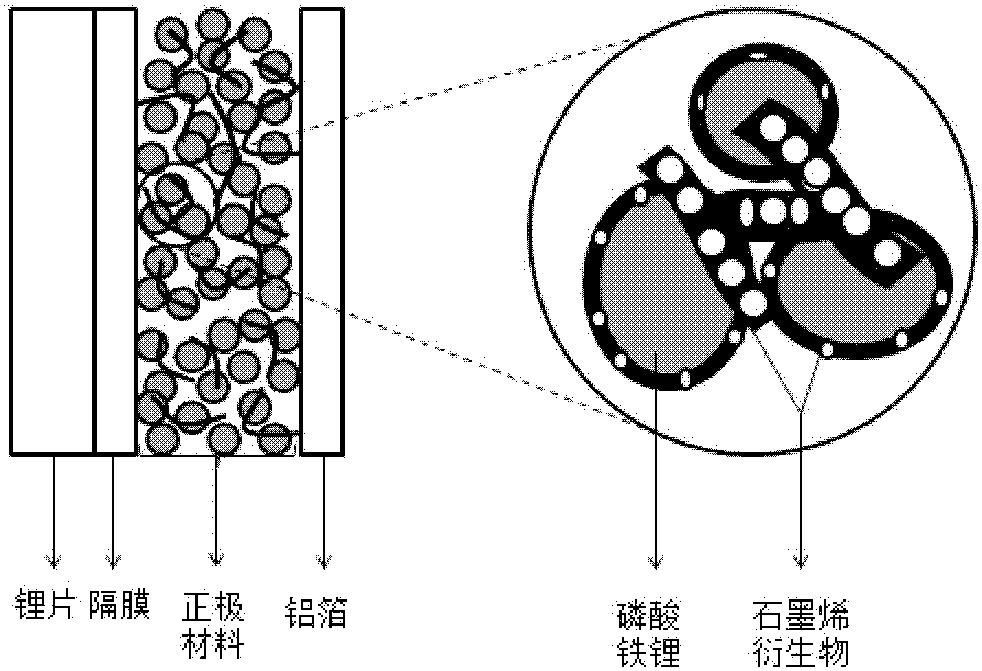

A kind of graphene-doped lithium iron phosphate cathode material and preparation method thereof

A positive electrode material, lithium iron phosphate technology, applied in the field of lithium iron phosphate positive electrode material and its preparation, can solve the problems of low specific surface area and difficulty in forming effective channels, and achieve high battery capacity, high tap density and low internal resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Preparation of lithium iron phosphate material doped with graphene:

[0038] (1) Add lithium hydroxide, lithium nitrate, ammonium dihydrogen phosphate, ferrous sulfate and ferrous acetate to the aqueous solution according to the atomic ratio Li:Fe:P=3:1:1 to form a mixed solution.

[0039] (2) Weigh 1.0g of graphene three-dimensional derivative material (the surface has a large number of micropores with a pore size ranging from 2nm to 100nm), add it to 50ml of concentrated sulfuric acid, slowly add 3.5g of potassium permanganate under stirring, and stir at room temperature for reaction After 0.5 hours, slowly add 100ml of deionized water, dropwise add hydrogen peroxide until no bubbles are generated, filter and wash with deionized water until neutral, and dry to obtain a three-dimensional graphene oxide derivative material. Dissolving the three-dimensional graphene derivative material obtained by drying in an aqueous solution, and ultrasonically obtaining a dispersed...

Embodiment 2

[0045] 1. Preparation of lithium iron phosphate material doped with graphene:

[0046] (1) Add lithium carbonate, lithium hydroxide and lithium acetate, ammonium ferrous phosphate, ferrous chloride and ferrous nitrate to the aqueous solution according to the atomic ratio Li:Fe:P=3:1:1 to form a mixed solution.

[0047] (2) Weigh 5.0g of graphene three-dimensional derivative material (its conductivity is greater than 100mS / m), add it to 100ml of concentrated sulfuric acid, slowly add 17.5g of potassium permanganate under stirring, stir and react at room temperature for 1.5 hours, then slowly add 300ml deionized water, add hydrogen peroxide dropwise until no bubbles are generated, filter and wash with deionized water until neutral, and dry to obtain a three-dimensional graphene oxide derivative material. Dissolving the three-dimensional graphene derivative material obtained by drying in an aqueous solution, and ultrasonically obtaining a dispersed and stable graphene three-dimen...

Embodiment 3

[0051] 1. Preparation of lithium iron phosphate material doped with graphene:

[0052] (1) Add lithium hydroxide, lithium nitrate, ammonium dihydrogen phosphate, ferrous sulfate and ferrous acetate to the aqueous solution according to the atomic ratio Li:Fe:P=3:1:1 to form a mixed solution.

[0053] (2) Weigh 1.0g of graphene three-dimensional derivative material (its conductivity is greater than 100mS / m), add it to 50ml of concentrated sulfuric acid, slowly add 4g of potassium chromate under stirring, stir and react at room temperature for 5 hours, then slowly add 100ml to remove Ionized water, add hydrogen peroxide dropwise until no bubbles are generated, filter and wash with deionized water until neutral, and dry to obtain a three-dimensional graphene oxide derivative material. Dissolving the three-dimensional graphene derivative material obtained by drying in an aqueous solution, and ultrasonically obtaining a dispersed and stable graphene three-dimensional derivative mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com