Infrared thermal imaging online monitoring method and system of petrochemical selective key equipment

A technology of infrared thermal imaging and key equipment, which is applied to fire alarms that rely on radiation effects, and can solve problems such as internal anti-corrosion layer damage, valve gasket instability, and unstable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

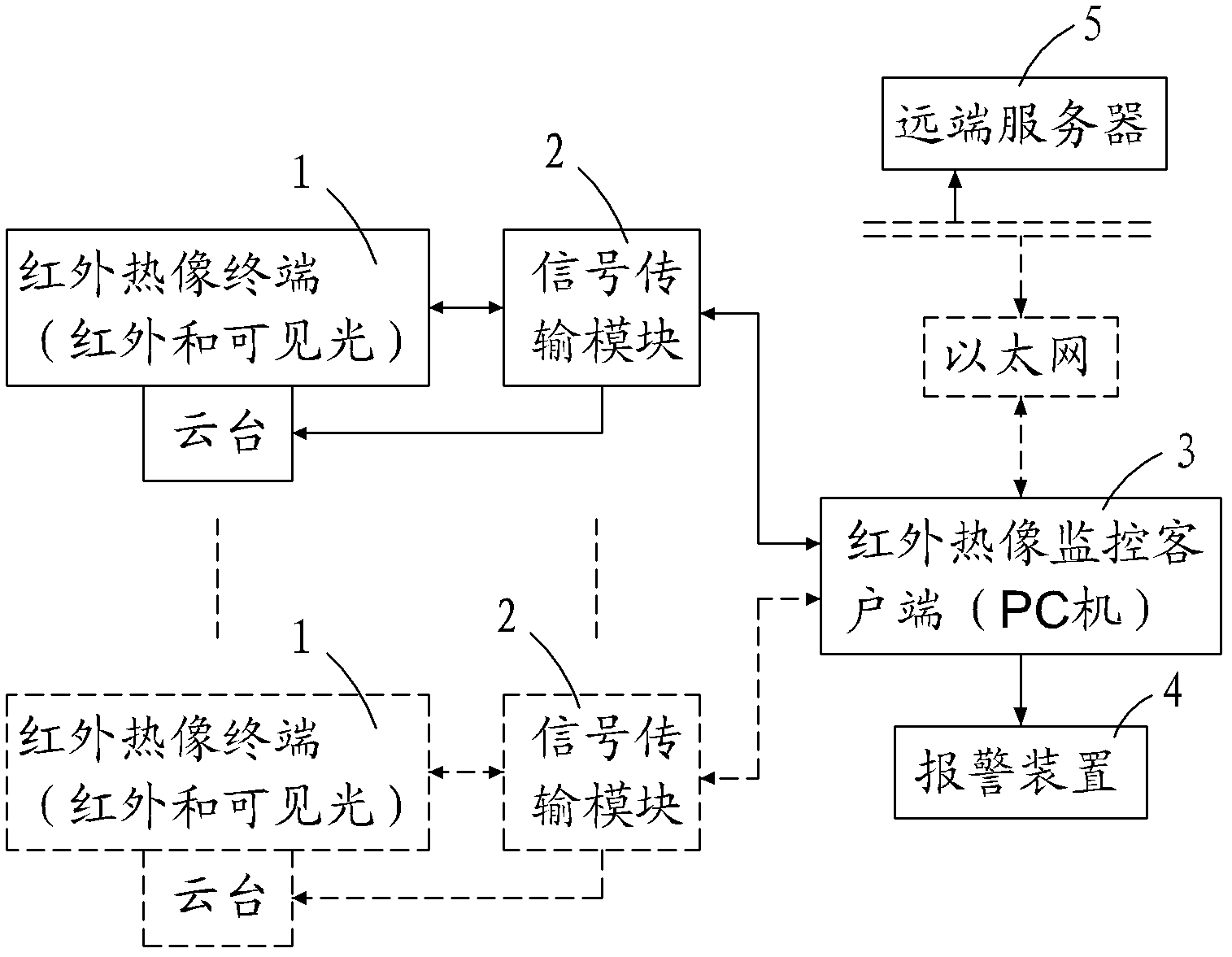

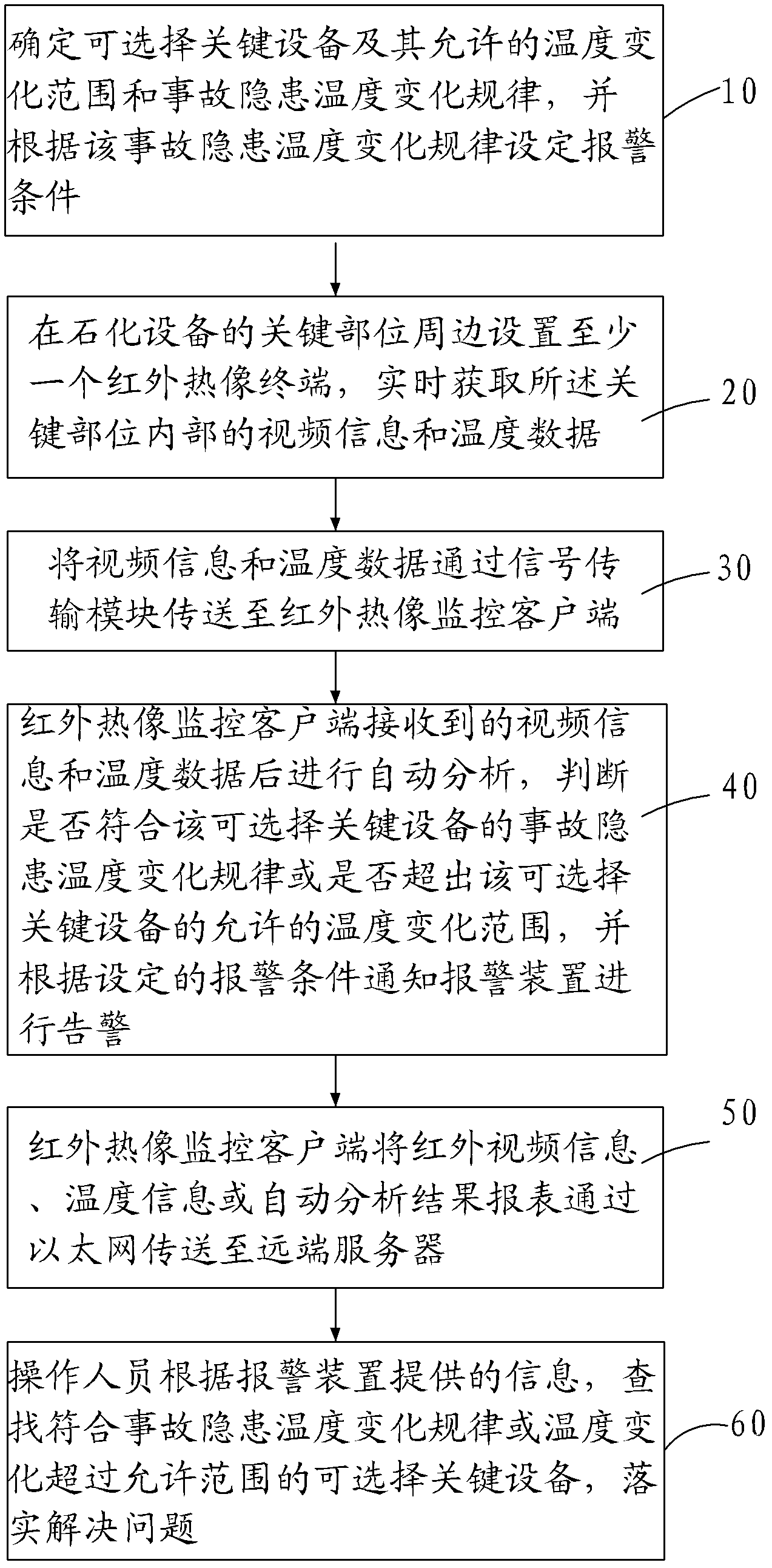

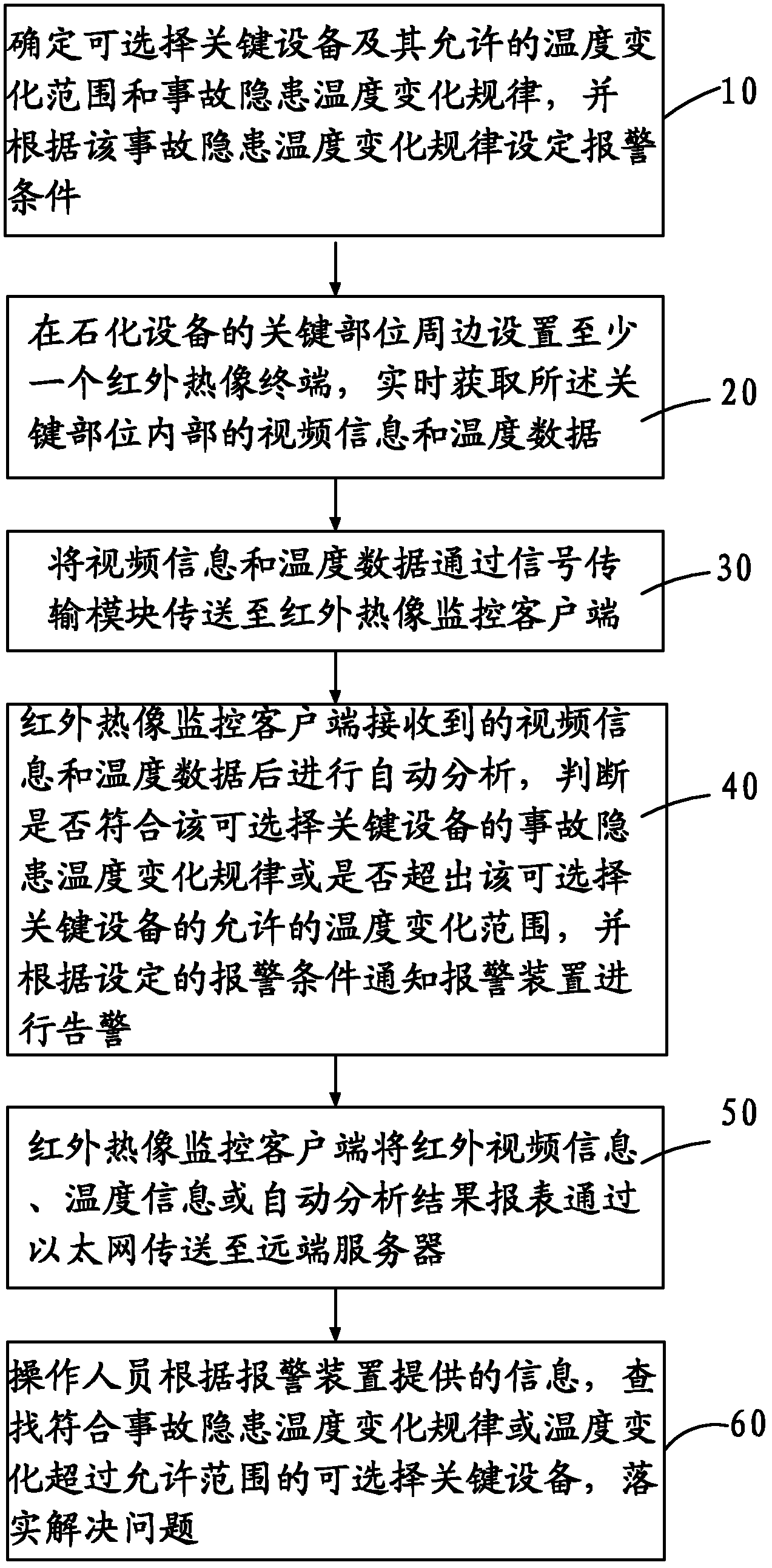

[0032] see figure 1 As shown, a preferred embodiment of the monitoring system of the present invention includes a plurality of infrared thermal image terminals 1, a plurality of signal transmission modules 2, an infrared thermal image monitoring client 3, and an alarm device 4, and the plurality of infrared thermal image The terminal 1 is set around the key parts of the optional key equipment (not shown) of the petrochemical industry. Each infrared thermal image terminal 1 is connected to the infrared thermal image monitoring client 3 through a signal transmission module 2. The infrared thermal image monitoring The client terminal 3 is then connected to the alarm device 4 .

[0033] The infrared thermal imaging terminal 1 further includes an infrared thermal imaging module 11, a temperature analysis module 12 and a visible light auxiliary camera 13, and the infrared thermal imaging module 11, temperature analysis module 12 and visible light auxiliary camera 13 are all connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com