Preparation method of optical diffusion film

A technology of optical diffusion and diffusion film, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc. It can solve the problems of light brightness and low scattering uniformity, so as to improve the light gathering ability and brightness and the effect of scattering uniformity, high brightness and scattering uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

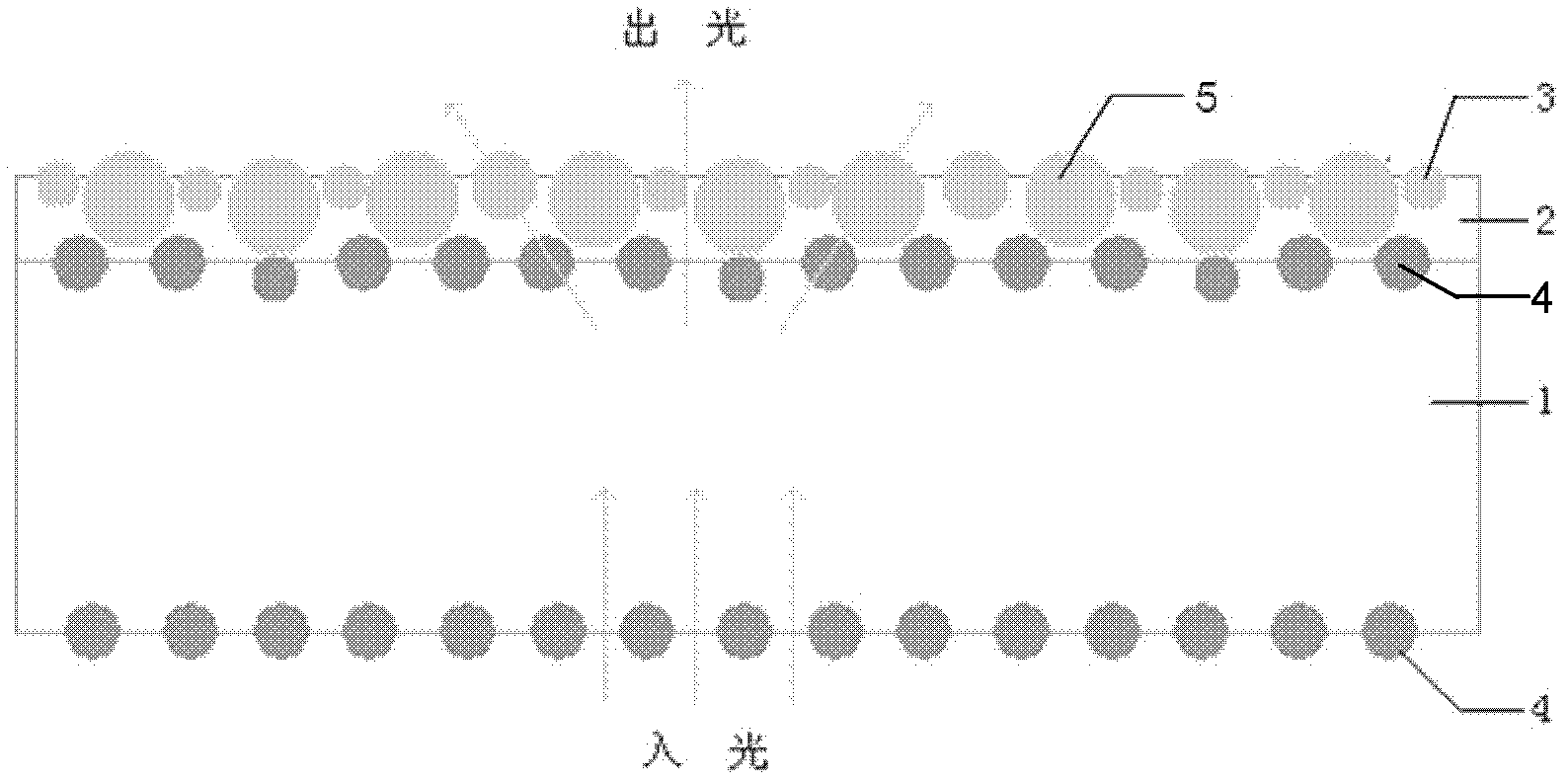

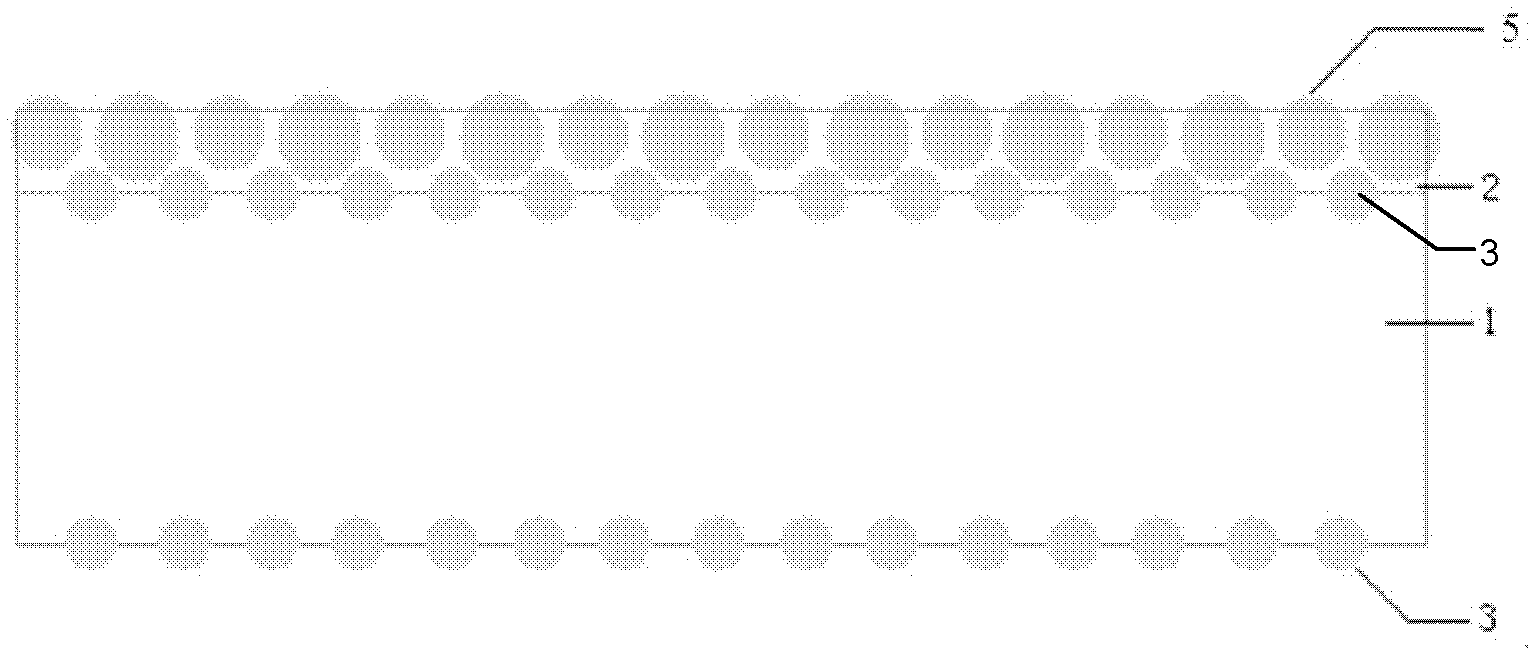

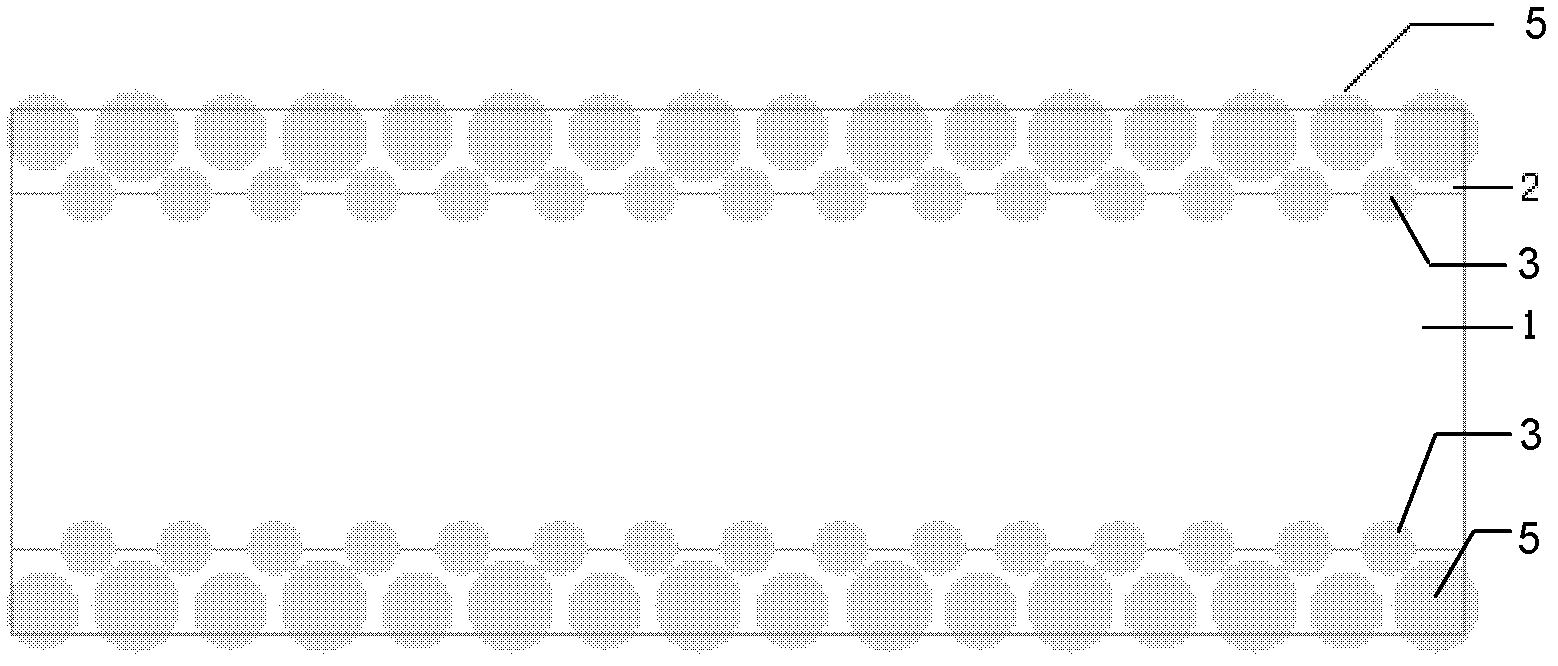

[0046] The preparation method of the optical diffusion film provided by the invention comprises the following steps:

[0047] Step 1. Preparation of scattering masterbatch

[0048] Mix the calculated amount of small particle scattering particles with polyester chips evenly, so that the weight content of scattering particles in the masterbatch is 4g-8g / kg, preferably 6g / kg (6000ppm), and then melt, extrude, and pelletize. Prepare the scattering masterbatch;

[0049] Step 2, preparation of substrate

[0050] Mix the scattering masterbatch obtained in step 1 with the polyester chip, wherein the weight ratio of the scattering masterbatch to the polyester chip is 30-50:70-50 to make a mixture A, and the obtained mixture A and the base material B Carry out melting and plasticizing separately, and the obtained melt enters the die head of the three-layer co-extruder through the distributor. The two outer layers are the mixture A, and the middle layer is the base material B. Two-way...

Embodiment 1

[0059] The diffusion film was prepared according to the above method, the thickness of the base film was 75 μm; the base film was an ABA three-layer co-extrusion structure, and the ratio of the diffusion masterbatch and the bright slice in the A layer was 42:58. Single-sided coating of large particle scattering particles, the particle size of the large particle scattering particles in the diffusion coating is 40 μm-60 μm, the large particle scattering particles account for 18% of the entire diffusion coating, and the amount of the thinner is 35% of the total weight of the coating solution . The final diffusion film thickness was 135 μm. The measurement results of the optical properties (light transmittance, haze) of the obtained film are shown in Table 1.

Embodiment 2

[0061] The diffusion film was prepared according to the above method, the thickness of the base film was 150 μm; the base film was an ABA three-layer co-extrusion structure, and the ratio of the diffusion masterbatch and the bright slice in the A layer was 40:60. Coating large particle scattering particles on one side, the particle size of the large particle scattering particles in the diffusion coating is 60 μm-80 μm, the large particle scattering particles account for 26% of the entire diffusion coating, and the amount of the thinner is the total weight of the coating solution 50% of. The final diffusion film thickness was 230 μm. The measurement results of the optical properties (light transmittance, haze) of the obtained film are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com