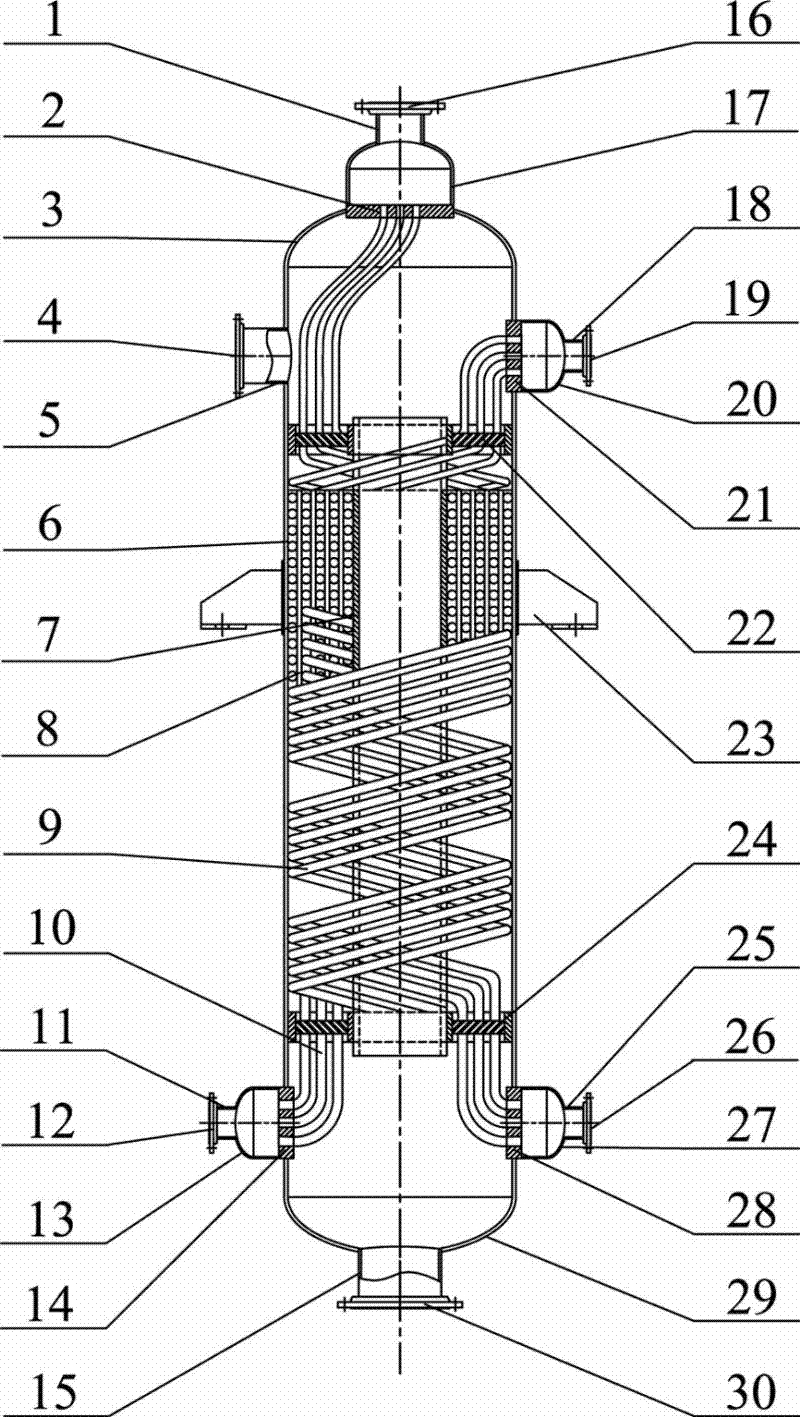

Liquefied natural gas (LNG) low temperature liquefied three-level refrigeration spiral wound tube type heat exchanger

A spiral winding, tube heat exchange technology, applied in liquefaction, indirect heat exchanger, heat exchanger type, etc., can solve the problems of pipeline leakage, large volume, poor self-shrinking ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Connect the natural gas pipeline with a secondary outlet temperature of -120°C to the connecting pipe 25, and the natural gas enters the natural gas inlet pipe box 27 at -120°C and 5.5 MPa, and is distributed in the pipe box 27 to each branch pipe of the natural gas spiral pipe bundle 9, and the pipe bundle 9 N in cylinder 6 and throttled after spiral winding 2 —CH 4 The mixed refrigerant performs heat exchange. When the temperature drops to -161°C and the pressure drops to 5.3 MPa, it is completely liquefied and supercooled, and flows to the pipe box 17 after being supercooled; Connecting pipe 1 flows out of the third-stage refrigeration device, and after throttling and reducing the pressure of the fourth-stage throttle valve, it is sent to the LNG storage tank; connect the mixed refrigerant pipe before pre-cooling to connecting pipe 11, N 2 —CH 4 The mixed refrigerant enters the mixed refrigerant pre-cooling tube box 13 at -120°C and 1.58 MPa, and then distributes i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com