Double-row pressurized volumetric type lubricating medium quantitative distributor

A kind of lubricating medium, volumetric technology, applied in the field of lubricating system, can solve the problems of long main pipeline, long overall length, main pipeline unfavorable for the installation of lubricating medium quantitative distributor, short unloading time, easy installation and improved sensitivity and the effect of oil output accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

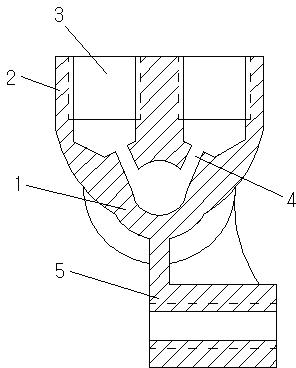

[0012] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

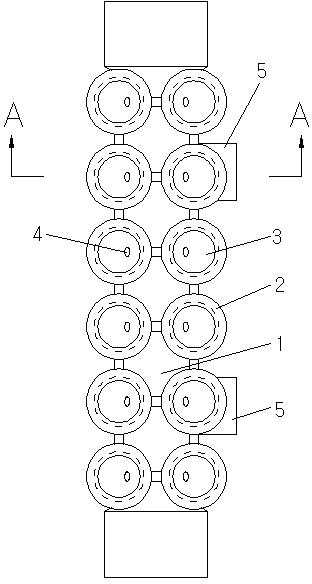

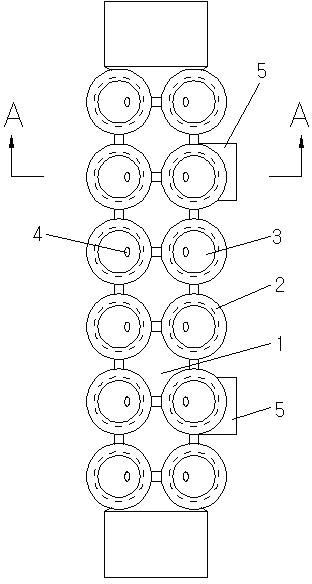

[0013] like Figure 1-Figure 2 As shown, a double-row pressurized volumetric lubricating medium quantitative distributor provided by the embodiment of the present invention includes a main pipeline 1 and a plurality of quantitative valves, and the pipe wall on one side of the main pipeline 1 is spaced along its axis. There are at least two main pipeline installation parts 5 fixedly, which are characterized in that:

[0014] One side of the main pipeline 1 is provided with a plurality of quantitative valve mounting parts 2 arranged in two rows and multiple rows along its axis, and each quantitative valve mounting part 2 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com