Hexagonal tower structure of wind driven generator

A wind turbine tower, hexagonal technology, applied in the field of hexagonal wind turbine tower structure, can solve the problems of heavy offshore wind turbine foundation, increased size and shape, expensive manufacturing cost, etc., to achieve cheap manufacturing cost, light weight, The effect of beautiful structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

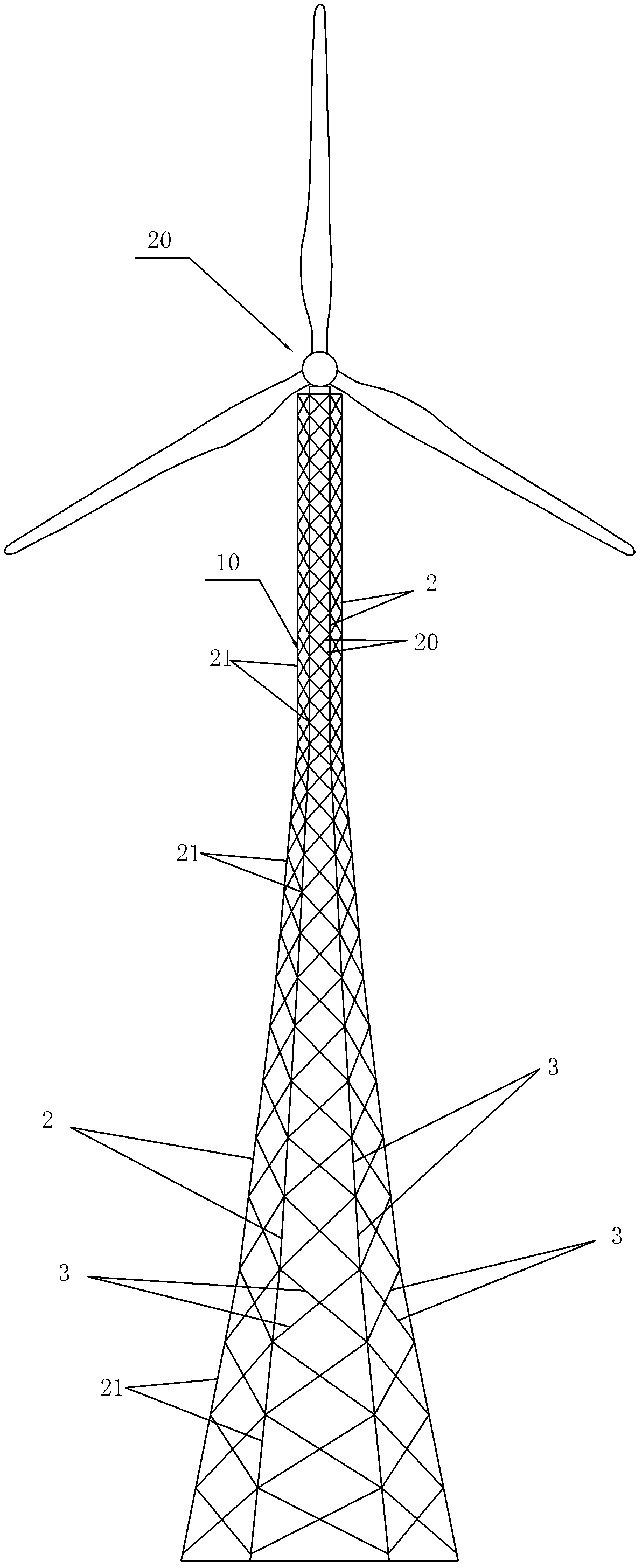

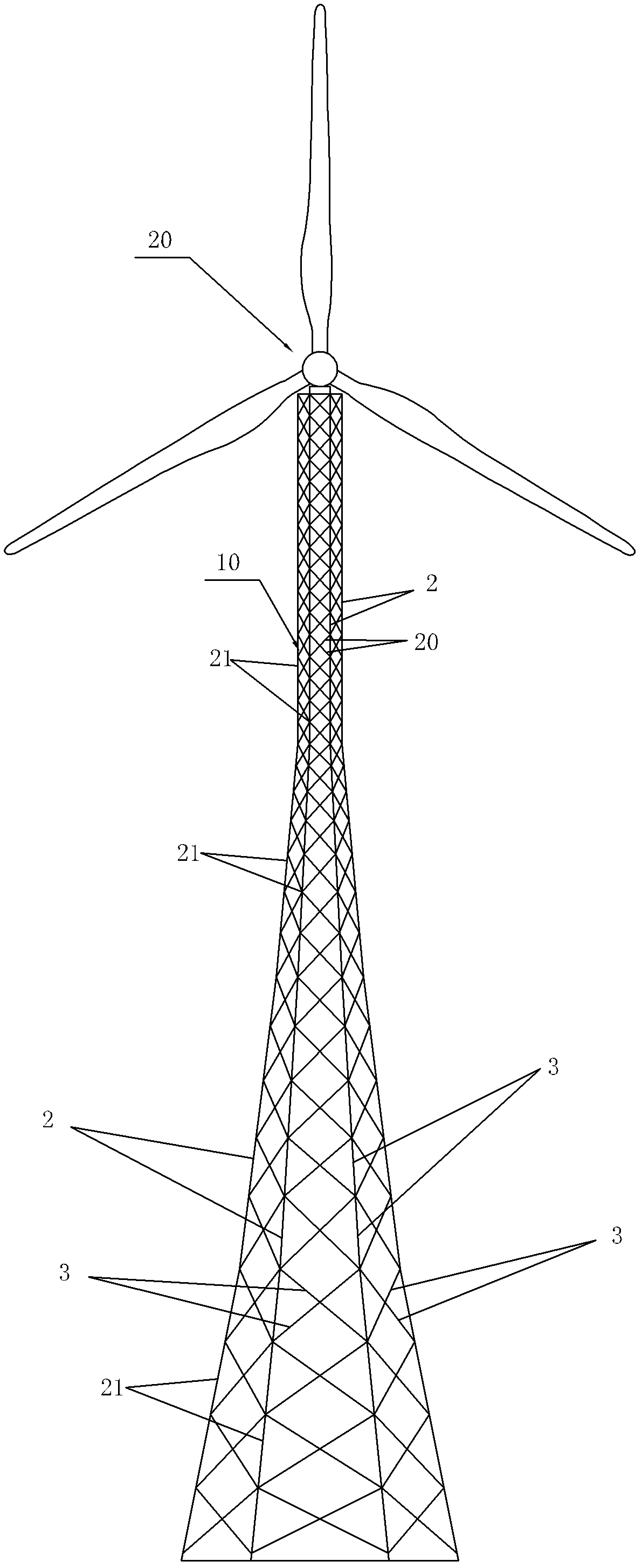

[0013] A hexagonal fan tower structure, which includes a tower main body 10, a fan impeller 20 is arranged on the tower main body 10, the tower main body 10 is a truss structure, and the tower main body 10 includes a plurality of support columns 2 and Reinforcing connecting rods 3 connected between adjacent supporting columns 2; the number of supporting columns 2 is six, and the six supporting columns 2 are arranged in a symmetrical hexagonal shape; the supporting columns 2 are composed of multi-section supporting connecting rods 21 through bolts Riveted or welded.

[0014] In order to enhance the rigidity and stability of the tower, the reinforcing connecting rods 3 are connected between the adjacent support columns 2 in pairs; or the reinforcing connecting rods 3 are connected between the adjacent supporting columns 2 in a triangular shape.

[0015] When the present invention is used in offshore wind power generators, the bottom foundations of multiple support columns 2 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com