Method for solving detonation of high compression ratio internal combustion engine

A technology of internal combustion engine and turbine, applied in the field of solving high compression ratio internal combustion engine deflagration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

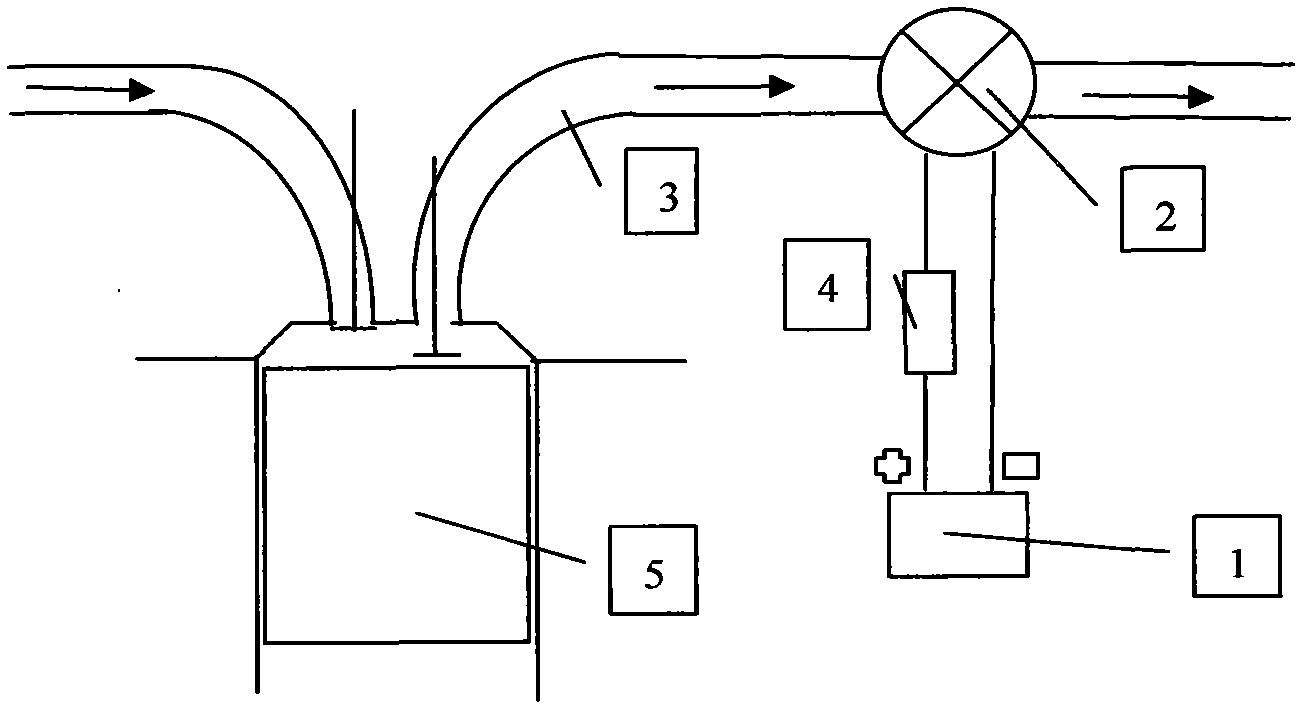

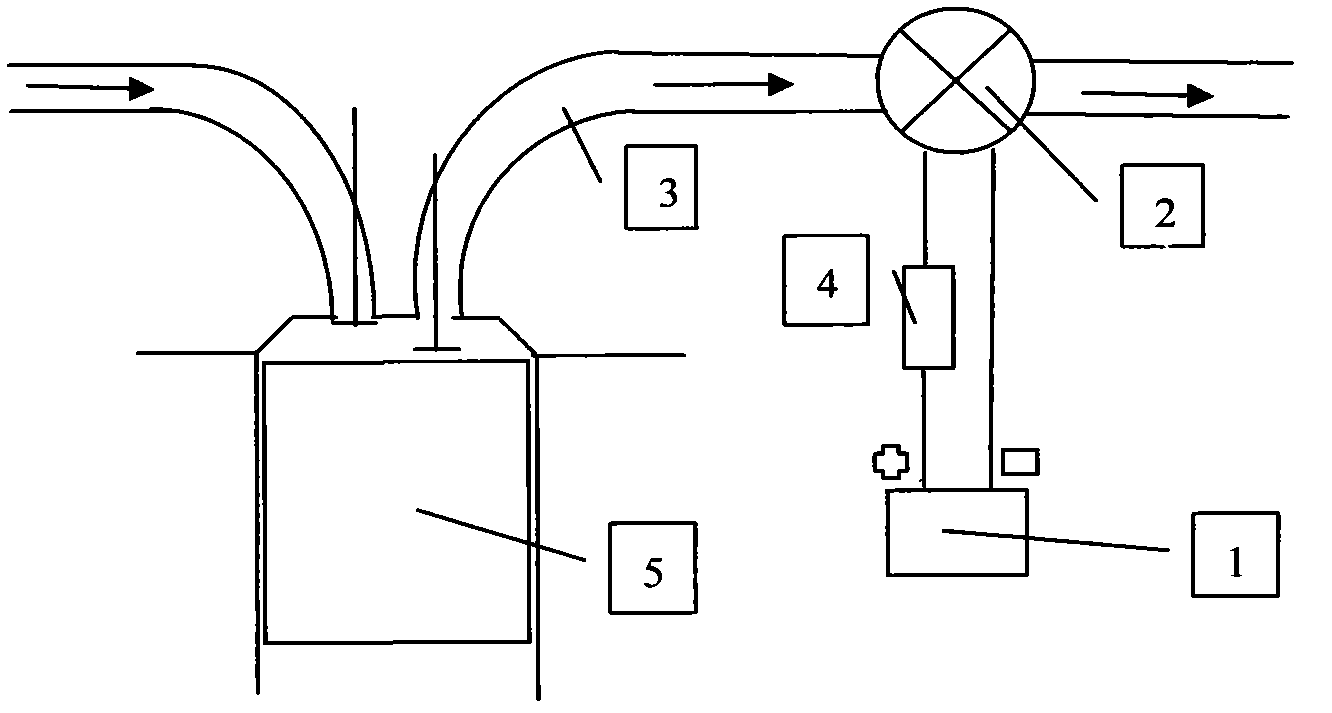

[0005] The exhaust pipe (3) of the internal combustion engine (5) is provided with an electric drive turbine (2) powered by a battery (1), which accelerates the discharge of exhaust gas from the internal combustion engine (5) and reduces the exhaust gas at the end of the combustion chamber exhaust stroke of the internal combustion engine (5) , so that the temperature of the mixture of fresh air and residual exhaust gas entering the combustion chamber of the internal combustion engine (5) during the intake stroke is reduced, thereby reducing the possibility of deflagration of the internal combustion engine (5). The rotational speed of the electrically driven turbine (2) can be increased and decreased through the control module (4) according to the rotational speed of the internal combustion engine, so as to meet various working conditions of the internal combustion engine (5).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com