Method for deep treatment of oil layer through self-generation foam acidification

A self-generated foam and advanced treatment technology, which is applied in the field of advanced treatment of oil layers, can solve the problems of inability to remove pickling products in time, affecting the timely removal of pickling products, influence of oil well treatment measures, etc., so as to improve the effect of measures and save the use of special equipment , the effect of high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Usually, after long-term consumptive exploitation in oilfields, the formation pressure has dropped significantly, and the pressure in some major blocks has dropped below 2MPa. The common chemical plugging removal method has poor plugging effect, high cost and short validity period. The deep treatment method of the self-generating foam acidizing oil layer of the present invention can effectively solve this production problem. After the self-generating foam acidizing treatment, the self-generating system is added, which can not only achieve deep acidizing of the oil layer and supplement the energy of the formation, but also improve the recovery effect and save Nitrogen injection and nitrogen production equipment, easy construction.

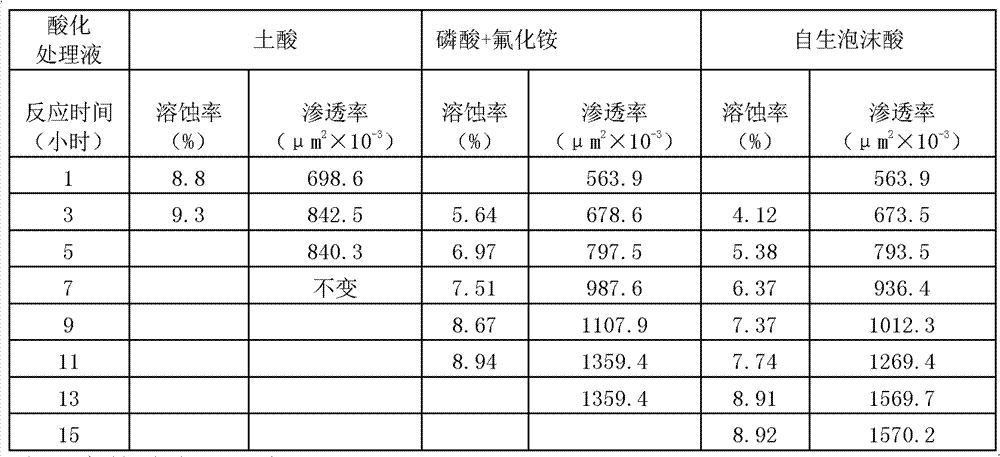

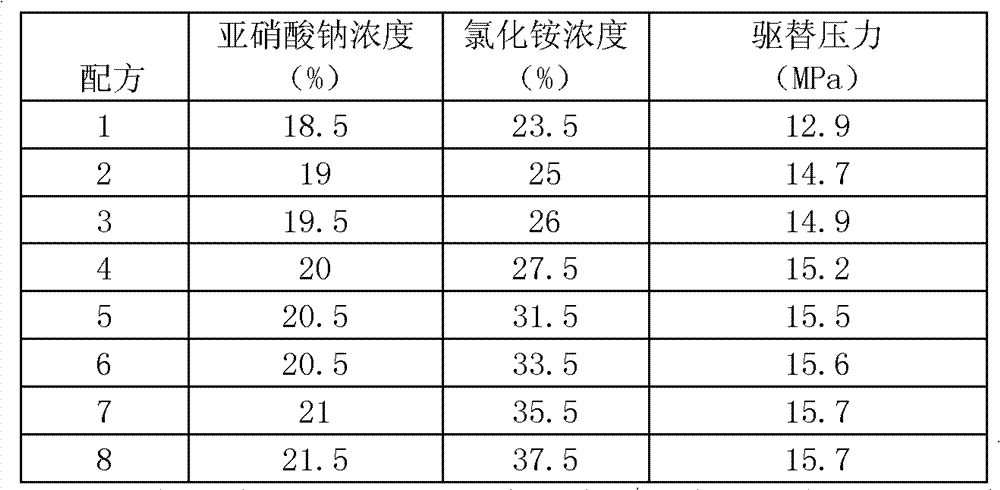

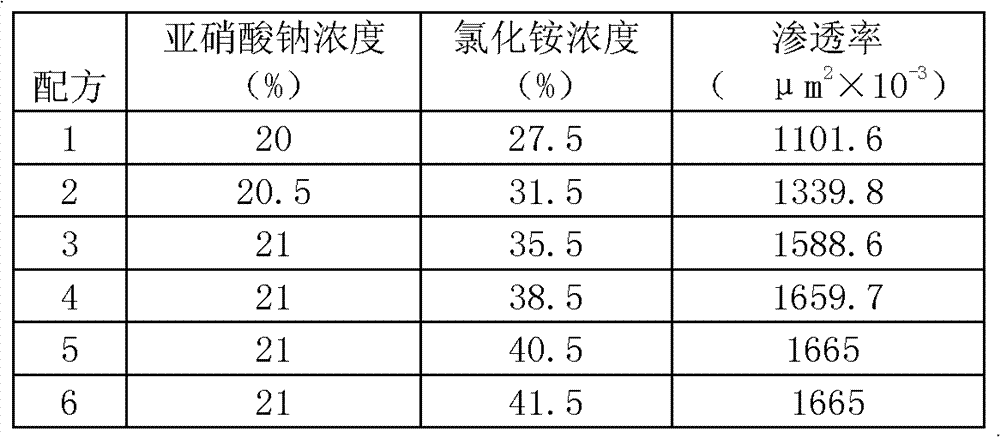

[0011] The self-generating foam acidizing oil layer advanced treatment method is a technology to clean the pores of the oil layer with organic solvents and surfactants. Specifically, under the conditions of formation temperature and a certain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com