Ball seat type rubber plug system for liner cementing

A liner cementing and ball seat type technology, which is applied in the direction of wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve the problems of time and resource waste, low drilling efficiency, etc., and save drilling time , reduce drilling time and save cementing operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

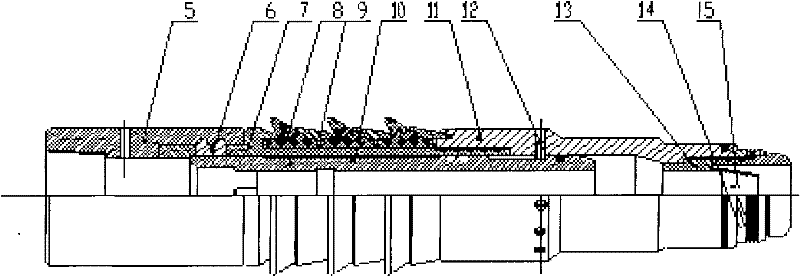

[0035] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0036] The ball seat type rubber plug system in the present invention is divided into three parts according to the placement position in the cementing string, that is, the drill pipe rubber plug that is put in from the wellhead when replacing the mud, and the liner that is placed under the feeding tool Rubber plugs and sockets at the bottom of the tailpipe.

[0037] The innovations of the present invention are: the ball holding mechanism of the tail pipe rubber plug, the locking and anti-rotation mechanism of the drill pipe rubber plug and the tail pipe rubber plug, the anti-rotation and locking mechanism of the tail pipe rubber plug and the supporting seat, specifically The structure is as follows:

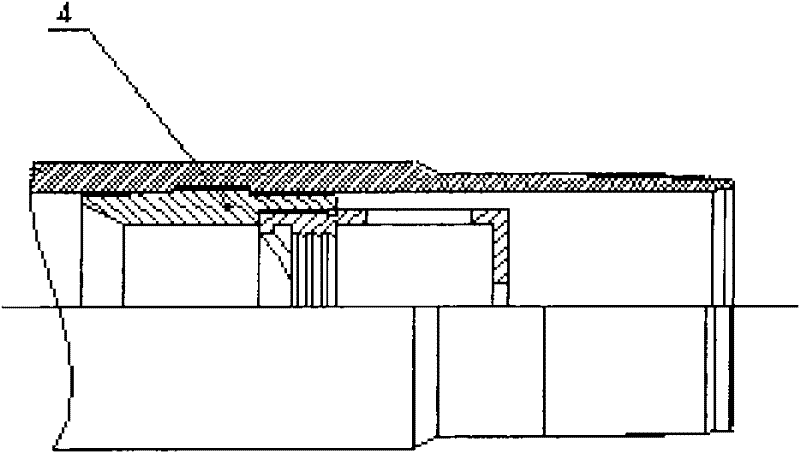

[0038] 1, such as figure 1 As shown, the drill pipe rubber plug includes a drill pipe rubber plug vulcanized cup 1 , a drill pipe rubber plug body 2 and an anti-retrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com