V-shaped drop-proof steaming box

A steaming box and anti-drip technology, applied in the direction of processing textile material containers, etc., can solve the problems of poor heat transfer effect, dripping, affecting the quality of finished carpet products, etc., and achieve the effect of temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

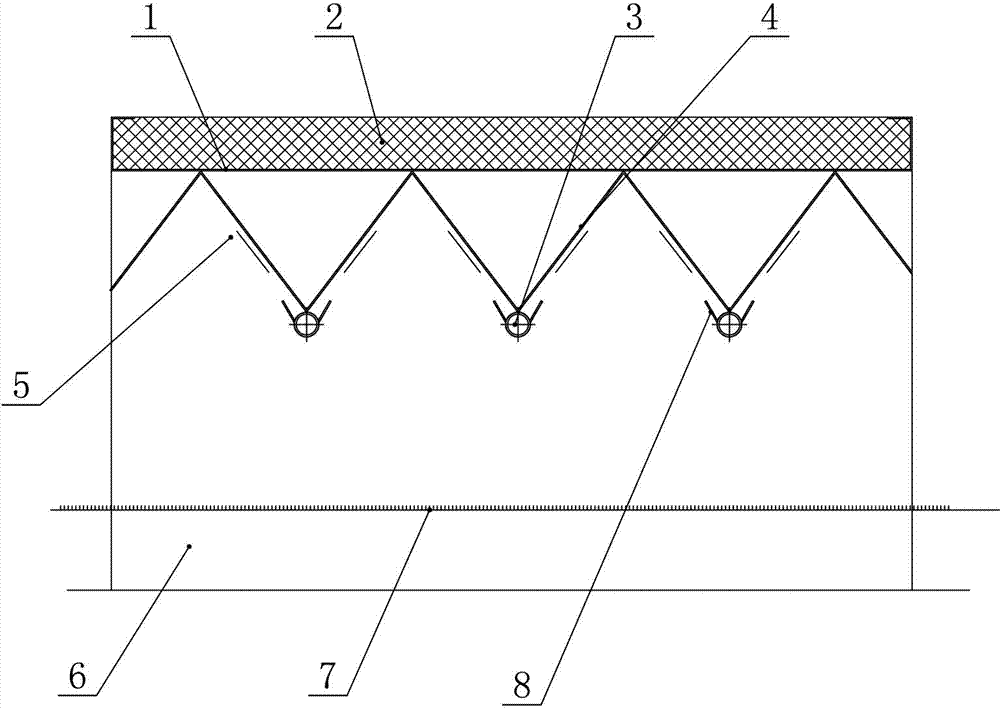

[0011] The present invention as figure 1 As shown, a V-shaped anti-drip steaming box includes a box top 1 and a steaming chamber 6. It is characterized in that: the steaming room 6 is located below the box top 1, and a V-shaped groove 4 is installed on the bottom of the box top 1. The lower end of the bottom of the V-shaped groove 4 is provided with an indirect heating pipe 3, and the two sides of the indirect heating pipe 3 are provided with water-blocking warp sheets 8. According to the V-shaped anti-drip steamer, it is characterized in that: thermal insulation cotton 2 is installed above the roof 1 of the tank.

[0012] The usage of the present invention is as figure 1 Shown: High-temperature steam is passed into the indirect heating pipe 3 during working hours. When the condensed water 5 flows into the heating tank on the inclined surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com