New method for recycling gallium from Bayer mother solution by using chelate resin

A technology of resin and liquid, applied in ion exchange of chelates, chemical instruments and methods, improvement of process efficiency, etc., to achieve high recovery rate of gallium, reduce energy consumption and cost, and achieve high-grade effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

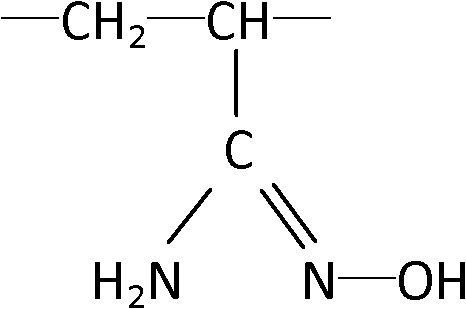

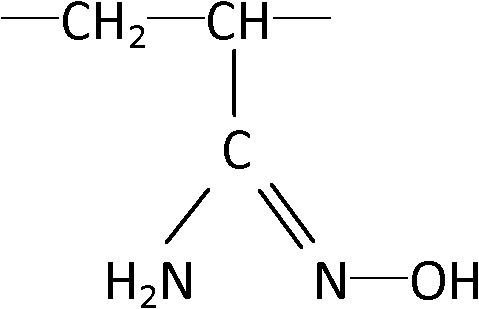

Method used

Image

Examples

Embodiment 1

[0028] Take 500L of LSC-600 resin and put it in the exchange column, let 25m 3 The Bayer mother liquor with a gallium content of 252mg / L was adsorbed by intermittent dynamic column passing. The flow rate is controlled at 3m 3 / h, when the flow rate at the outlet of the exchange column is 1.8m 3 / h (that is, 60% of the set flow rate), start stirring, and then the outlet flow rate slowly recovers, when the flow rate reaches 2.88m 3 / h (being 96% of the set flow rate), stop stirring, and the time of the whole intermittent dynamic column adsorption is 13h. After saturated adsorption, wash with water until the pH is 6, add 300L of deionized water of pH7, start stirring, adjust the pH to 3 with 10% chloroacetic acid solution, and control the temperature at 30°C, keep stirring for 5min, filter out 360L of the eluting solution, measure The content of gallium in the solution was obtained to be 376 mg / L. Add 360L of the filtered eluent solution to the resin, start stirring, adjust t...

Embodiment 2

[0030] Take 250L of LSC-900 resin and put it in the exchange column, let 40m 3 The Bayer mother liquor with a gallium content of 252mg / L was adsorbed by intermittent dynamic column passing. The flow rate is controlled at 4m 3 / h, when the flow rate at the outlet of the exchange column is 2.8m 3 / h (that is, 70% of the set flow rate), start stirring, and then the outlet flow rate slowly recovers, when the flow rate reaches 3.8m 3 / h (being 95% of the set flow rate), stop stirring, and the time of the whole intermittent dynamic column adsorption is 12.5h. After the adsorption is saturated, wash with water until the pH is 7, add 300L of deionized water with a pH of 7, start stirring, adjust the pH to 4 with 98% concentrated sulfuric acid, and control the temperature at 20°C, keep stirring for 15min, and filter out 348L of the eluting solution , The measured gallium content in this solution is 175mg / L. Then add 348L of the filtered eluent solution into the resin, control the t...

Embodiment 3

[0032] Concrete implementation method is the same as embodiment 2, and difference is:

[0033] (1) After washing the saturated adsorption resin with water until the pH is 8, add 300 L of deionized water with pH = 7, adjust the pH to 0.1 with 70% phosphoric acid, control the temperature at 5° C., and stir for 10 min to obtain 360 L of eluting solution. The gallium content was 14.7g / L; the above eluate was poured into the exchange column again, the temperature was controlled at 3°C, and the pH was adjusted to 0.01 with 98% sulfuric acid to obtain 371L of desorption solution, and the measured gallium content was 15.6g / L.

[0034] (2) Impurity removal process: Add 2.86Kg aluminum hydroxide, 2.59Kg calcium oxide, 2.35Kg sodium sulfide, and 7.5Kg of 50% hydrogen peroxide to 102L sodium gallate solution, the total amount is 15.3Kg. The specific operation is as follows: After adding aluminum hydroxide and calcium oxide, stir and heat up to 105°C for 3 hours, cool down to 50°C, filter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com