Method for producing chemical raw material by hydrocracking

A chemical raw material, hydrocracking technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, hydrocarbon oil cracking, etc., can solve the problems of not being able to play the role of additives on the catalyst well, and the influence is very limited, to achieve Conducive to entry and exit and diffusion, reduce strong adsorption, improve nitrogen resistance and activity stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

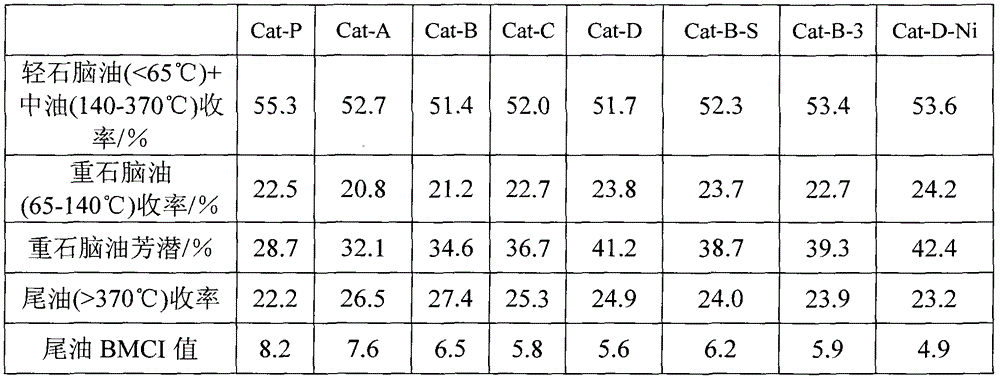

Embodiment 1

[0025] The preparation of embodiment 1 NiW / HY-β-ASA catalyst

[0026] Amorphous silica-alumina (ASA) was prepared according to the above comparative example. The composite carrier HY-β-ASA was prepared by mechanically mixing ASA, HY molecular sieve and β molecular sieve. The mass contents of ASA, Y molecular sieve and β molecular sieve in the composite carrier were 70%, 24% and 6% respectively. Weigh 1.35g of nickel nitrate and 3.71g of ammonium metatungstate and dissolve in deionized water to make a co-impregnation solution, impregnate the composite carrier for 4 hours, dry in air at 120°C for 4 hours, and then bake in a muffle furnace at 500°C for 3 hours. Obtain catalyzer, metal content NiO is 4wt%, WO in the catalyzer 3 It is 24.0 wt%. This catalyst is designated cat-A.

Embodiment 2

[0027] The preparation of embodiment 2 NiW / CY-β-ASA catalyst

[0028] Add 100gHY molecular sieve to 500ml with a concentration of 1.0mol.L -1 In the citric acid solution, react at 60°C for 3 hours, then dry at 120°C for 2 hours, and bake at 500°C for 3 hours to obtain a modified Y-type molecular sieve, which is denoted as CY. The composite carrier and catalyst were prepared according to the method of Example 1, and the catalyst was designated as cat-B.

Embodiment 3

[0029] Embodiment 3 Preparation of NiW / CY / β1-ASA catalyst

[0030] CY molecular sieves were prepared according to the method in Example 2. CY molecular sieve and β molecular sieve are mixed and beaten, and the mass ratio of CY molecular sieve and β molecular sieve in the slurry is 8:2, and this slurry is recorded as A; according to the method of the comparative example, the amorphous silica aluminum is prepared, and the precipitant is added dropwise, and water is added. After the glass is aged, add the molecular sieve slurry A. After the aging, filter, wash, dry, shape, and roast the precipitate to obtain an in-situ composite carrier. The mass of the molecular sieve in the composite carrier accounts for 30% of the carrier, and the rest of the steps are carried out according to Example 1 prepares the catalyst, which is designated as cat-C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com