Insulating material for high-voltage cable and preparation method thereof

A cable and material technology, applied in the field of polyolefin resin composition, can solve the problem that the impurity content of the product cannot meet the design requirements, and achieve the effect of improving the cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

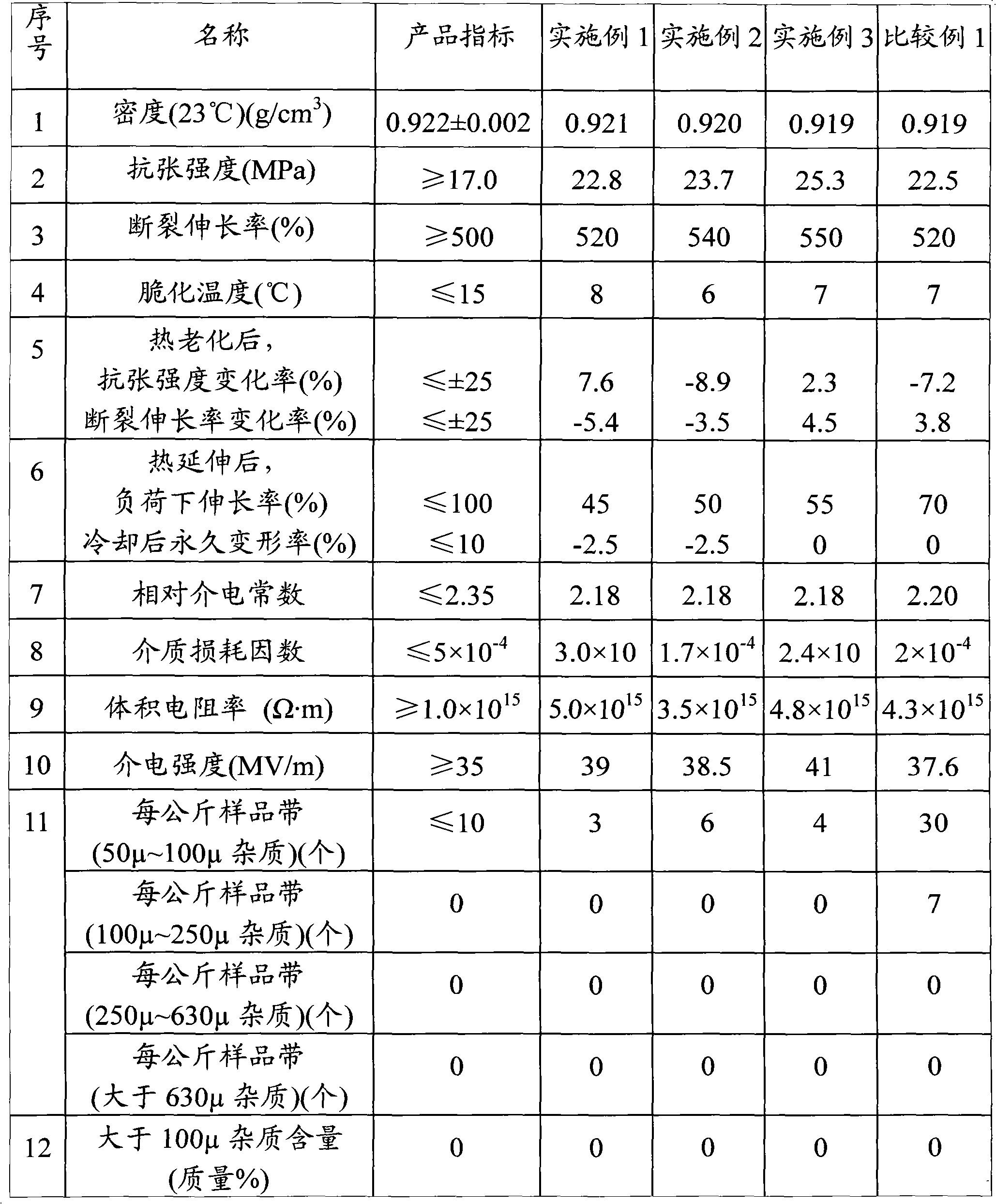

Examples

preparation example Construction

[0021] According to the preparation method of the polyolefin resin composition provided by the present invention, the method comprises: mixing, homogenizing and devolatilizing polyolefin and antioxidant at a temperature of 150°C-200°C under ambient conditions to obtain Molten material; the molten material is filtered at 180-230°C, then dehydrated, dried, and then mixed with a cross-linking agent.

[0022] Specifically, the method is as follows: adding polyethylene, antioxidant and optional additives according to their mass ratio to a twin-screw extruder for full mixing, dispersion, homogenization and devolatilization to obtain a molten material ; After the molten material is filtered through a 300-500 mesh filter mesh, it is granulated in a water ring, and then dehydrated by a dehydrator to obtain a granular premix. The method is to fully mix the dried and temperature-controlled granular premix with the liquid crosslinking agent so that the premix can fully absorb the liquid c...

Embodiment 1

[0031] At an air pressure of 12.5N / m 2 , the number of dust particles (dust) in the air cleanliness is lower than 0.33×10 8 Nr / m 3 , the ambient temperature is 20 ℃, and the relative humidity is under the environmental conditions of 85% or less, with 100 mass parts of polyethylene (density 0.922g / cm 3 , melt index 1.9g / 10min (190 ° C, 2.16kg)), 0.2 mass parts of antioxidant 300 as the main antioxidant and 0.04 mass parts of antioxidant DSTP as the auxiliary antioxidant through the loss-in-weight metering feeding device Put it into a twin-screw extruder for full mixing, dispersion, homogenization and devolatilization to obtain a molten material. The screw temperature is set at 110°C, 130°C, 150°C, 170°C, 180°C, 180°C and 180°C.

[0032] The molten material is filtered through a 500-mesh filter, followed by water ring cutting, and the temperature at the filter is set at 190°C and 190°C.

[0033] The granular premix is obtained by dehydration with a dehydrator, and the premix...

Embodiment 2

[0036] In addition to changing polyethylene to polyethylene with a melt index of 2.0g / 10min (190°C, 2.16kg), the amount of primary antioxidant to 1 mass part, the amount of auxiliary antioxidant to 2 mass parts and crosslinking Except that the consumption of the agent DCP was changed to 5 parts by mass, the polyolefin resin composition was prepared in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com