Cup fetching machine

A technology of a cup fetching machine and a robotic arm, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of waste of resources, low efficiency of the cup fetching machine, and the speed of the glass cup pressing machine cannot be improved. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

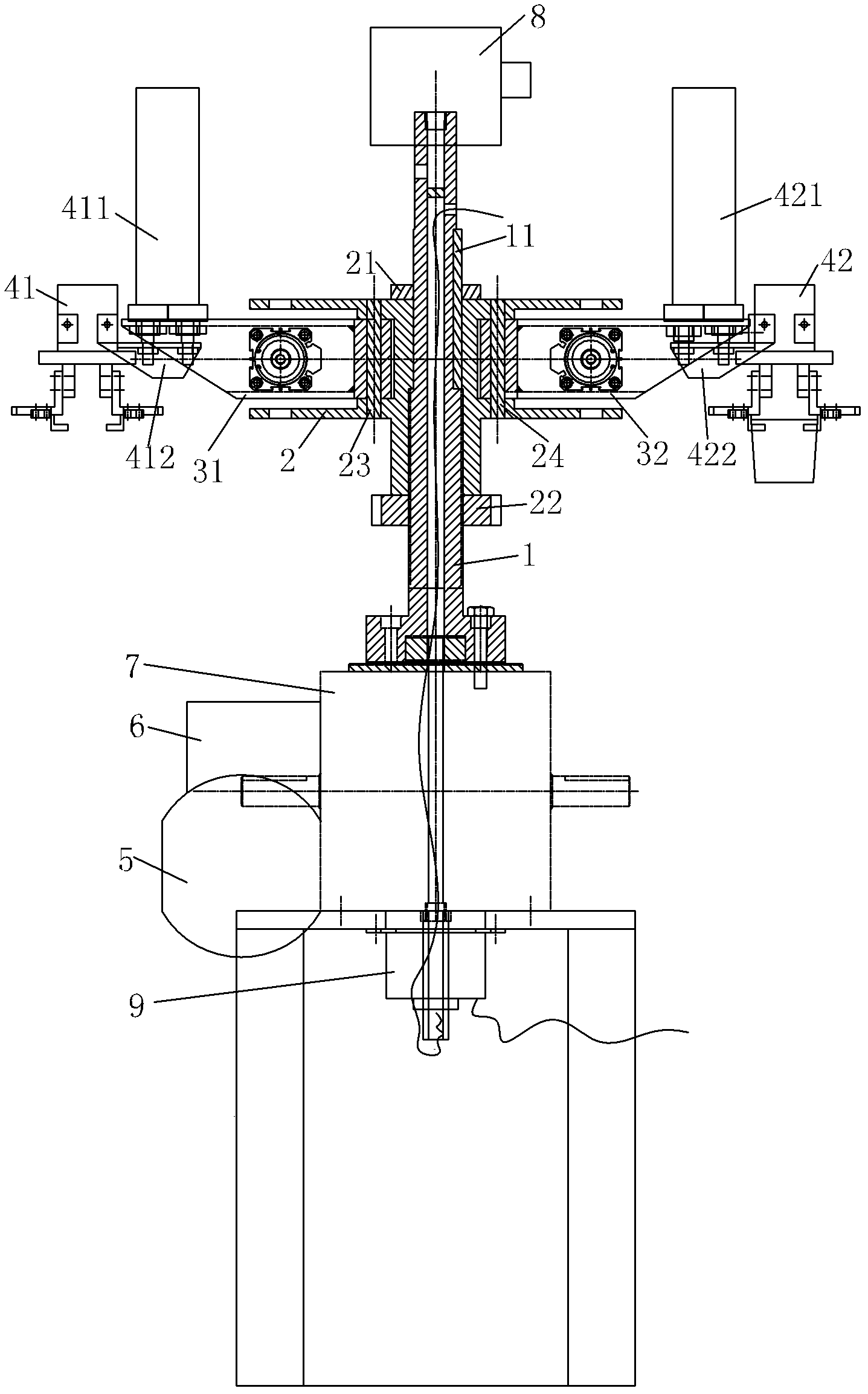

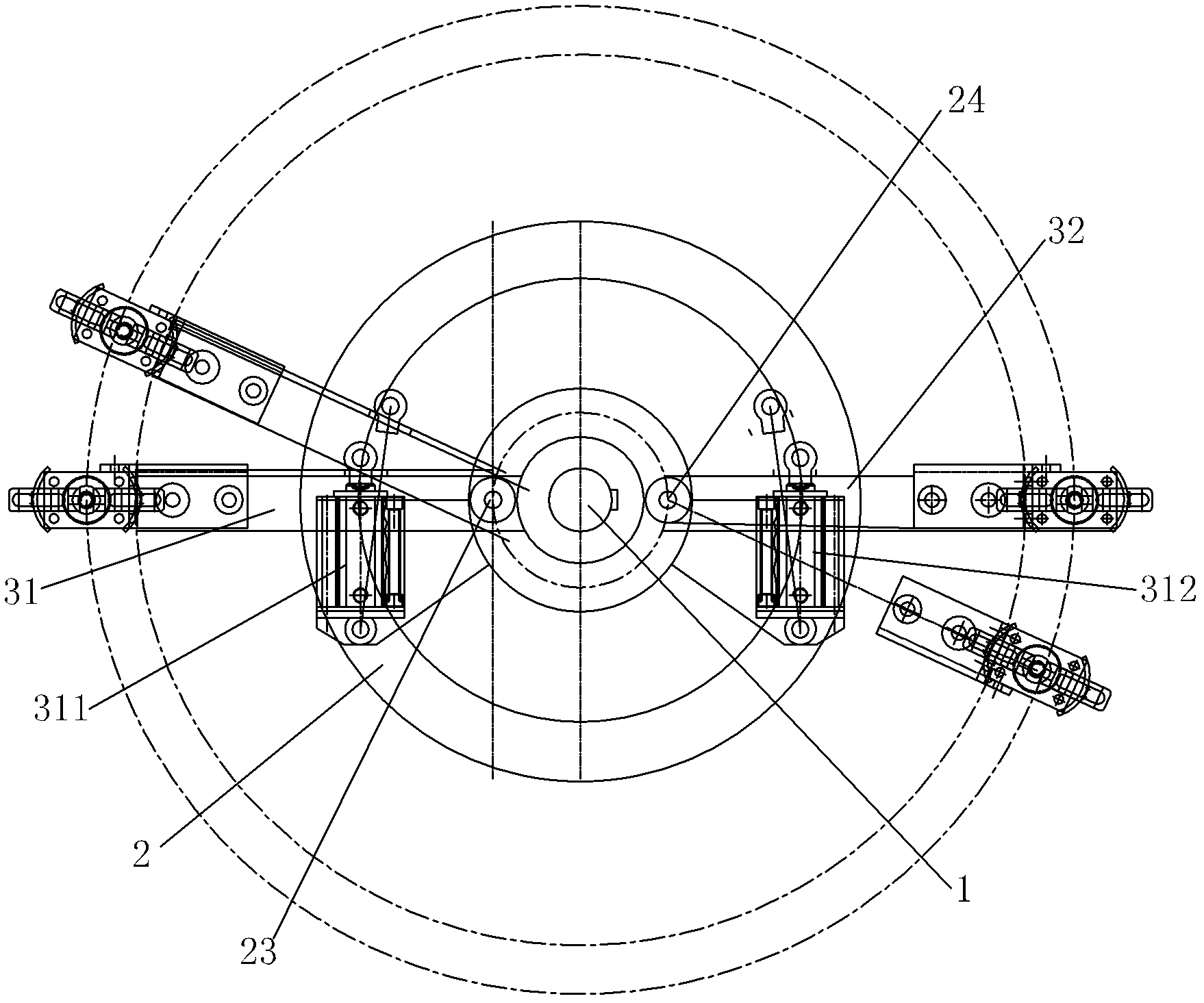

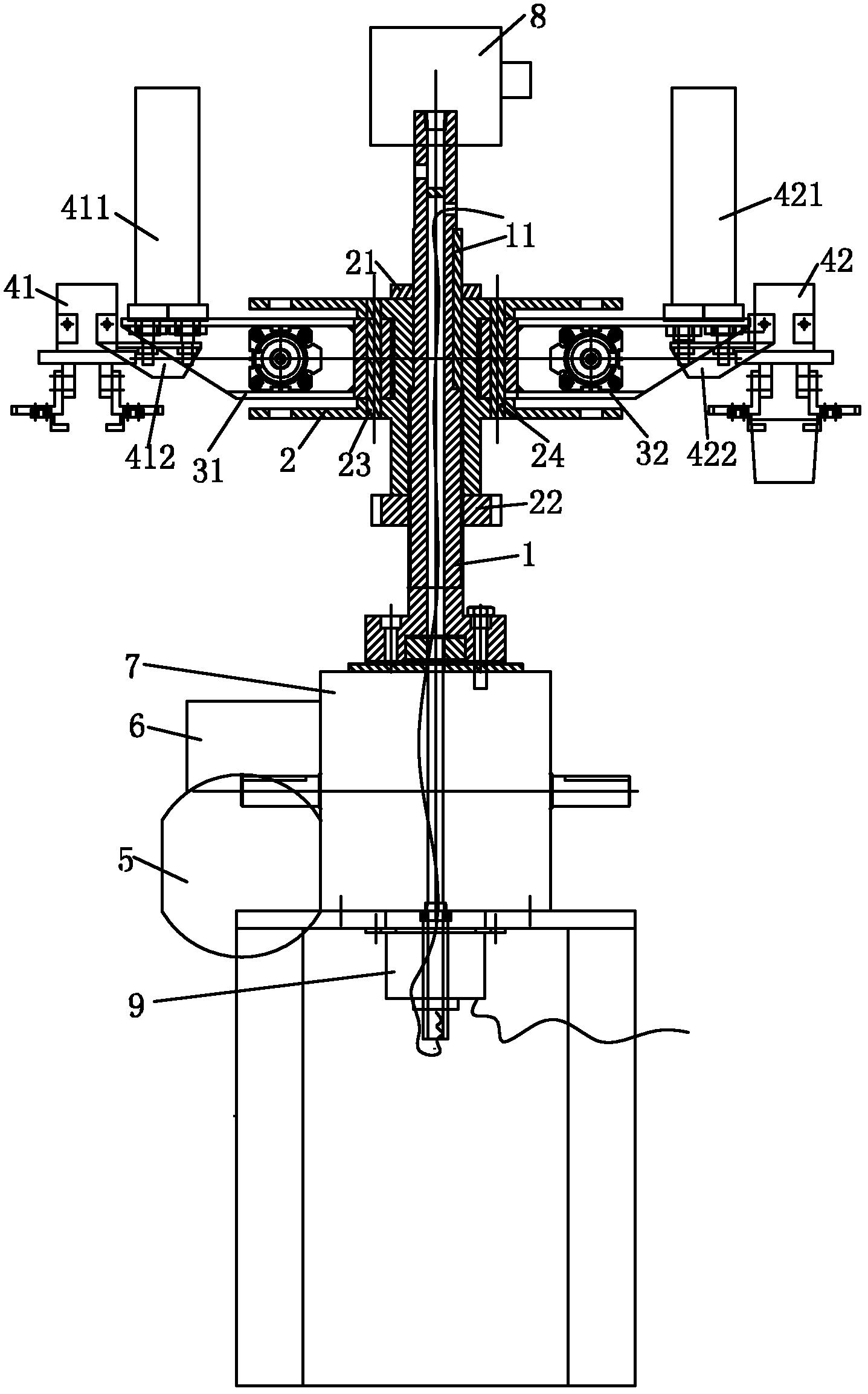

[0015] Such as figure 1 As shown, the cup taking machine of the present invention includes a rotating central axis 1, a sliding sleeve 2, first and second mechanical arms 31, 32, first and second air fingers 41, 42, an asynchronous motor 5, a worm gear reducer 6, a split Device 7, rotary joint 8, conductive slip ring 9, sliding sleeve 2 is set on the rotating central shaft 1, and there is a sliding positioning key 11 between the sliding sleeve 2 and the rotating central shaft 1, on the rotating central shaft 1, on the sliding sleeve 2. Upper and lower lock nuts 21 and 22 are screwed on the upper and lower ends respectively. The sliding sleeve 2 has two upper and lower discs. The sliding sleeve 2 is hinged with first and second hinge pins 23 and 24 respectively. Two mechanical arms 31, 32, the first and second mechanical arms 31, 32 are located between the upper and lower discs of the sliding sleeve 2, the distances from the first and second hinge pins 23, 24 to the center of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com