Automobile warm air control method and automobile warm air control device

The technology of a heating device and a control method is applied to the heating control of heating. , Demisting in the cockpit of electric vehicles, method and device for heating air control in automobiles, and defrosting field, which can solve the problems of expensive high-power relays, poor temperature control smoothness, softening of surrounding plastics, etc., to avoid excessive surface temperature and maintain Consistency and stability, the effect of increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

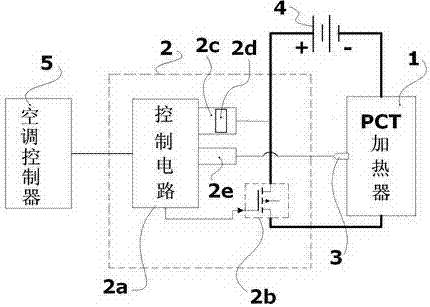

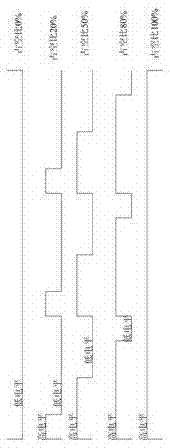

[0027] Such as figure 1 , image 3 As shown, the automobile warm air control method of the present invention includes the following steps: PTC heater 1 is loaded with strong electric voltage; 1 The temperature is compared with the target temperature value; the control circuit 2a detects the voltage and current of the strong current circuit of the PTC heater 1 through the photoelectric coupling strong and weak current isolation circuit 2d; it is characterized in that: the driving circuit 2b uses an edge-gate bipolar transistor (IGBT), Receive the duty cycle pulse width modulation signal output by the control circuit 2a to turn on or off the collector and emitter; the strong power supply 4 is applied to the PTC heater 1 through the drive circuit 2b insulated gate bipolar transistor (IGBT).

[0028] The drive circuit 2b insulated gate bipolar transist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com