Ink tank with movable partition for rainbow printing and its assembly method

A mobile, clapboard technology, used in general parts of printing machinery, printing, printing presses, etc., can solve the problems of inability to disassemble, move, complex ink tank manufacturing process, and inability to ink ratio, etc., and achieve stable and reliable quality of printed products. , Simple structure, adjustable position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

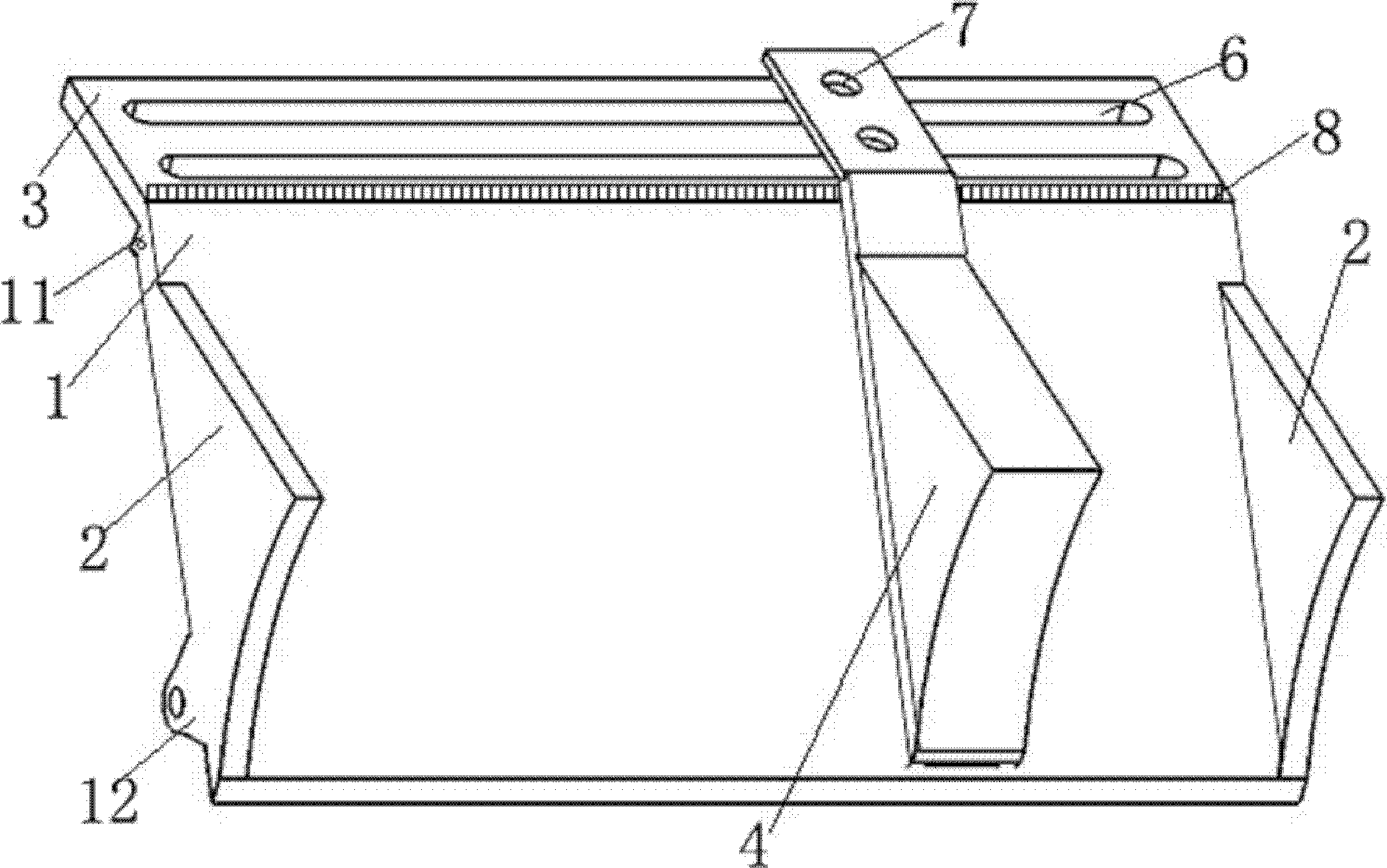

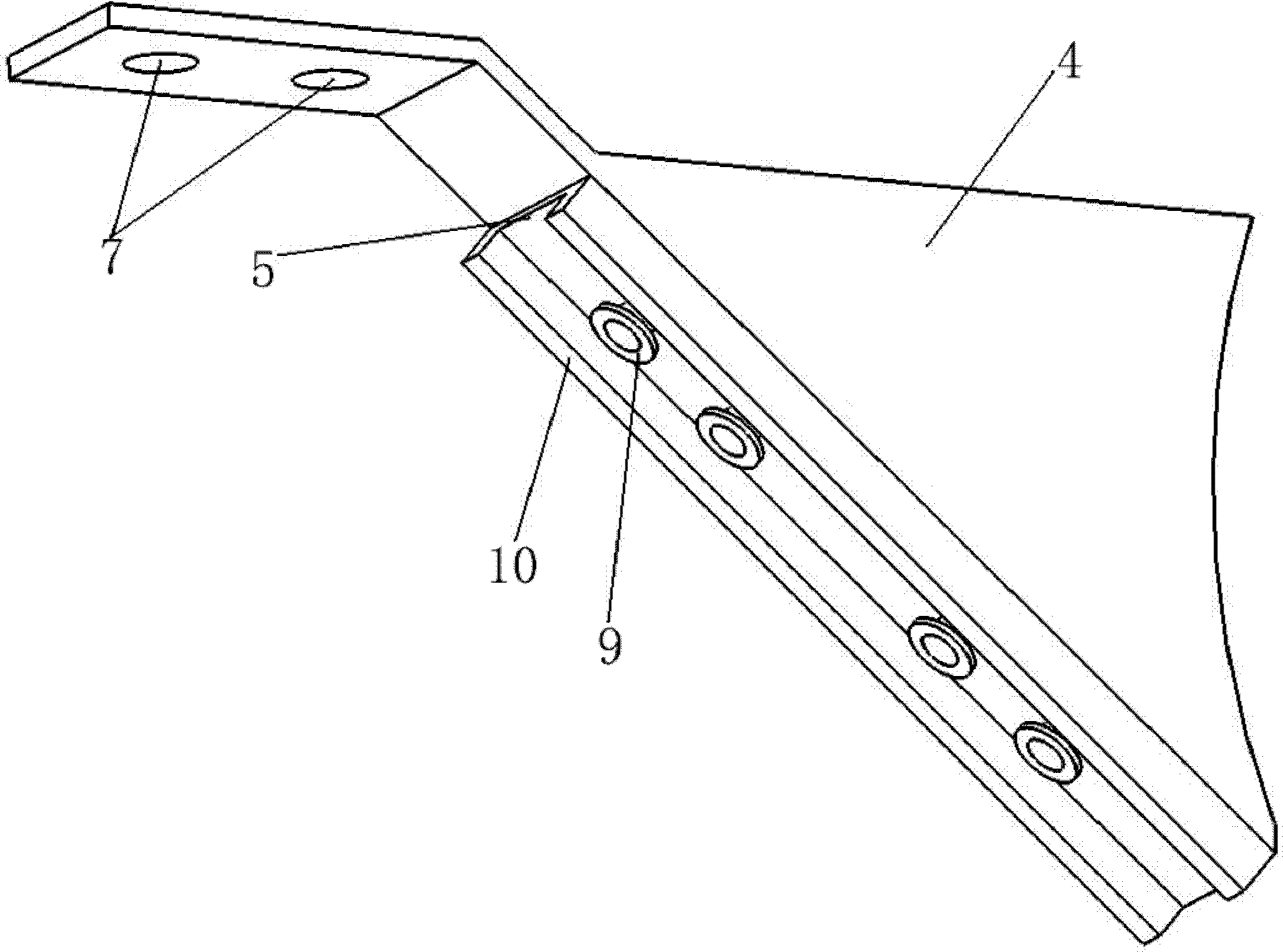

[0041] Such as figure 1 and figure 2As shown, an ink tank with a movable partition for rainbow printing includes a contact slope 1, arc side plates 2 arranged on both sides of the contact slope 1, one end of the contact slope 1 is obliquely fixed to the working platform 3, and Including the ink tank partition, the ink tank partition includes an arc partition 4 and a rubber pad 5, the rubber pad 5 is longitudinally arranged on the contact slope 1, the bottom of the rubber pad 5 is sealed with the contact slope 1, and the top of the rubber pad 5 is connected to the circle The arc partition 4 is sealed and fixed, the top of the arc partition 4 is movable and fixed on the working platform 3, and more than one ink tank partition is provided. The arc side plate 2 and the arc partition 4 have a similar triangular structure, and only one surface of the arc side plate 2 and the arc partition 4 has a radian, which is compatible with the outer diameter of the ink fountain roller. Exac...

Embodiment 2

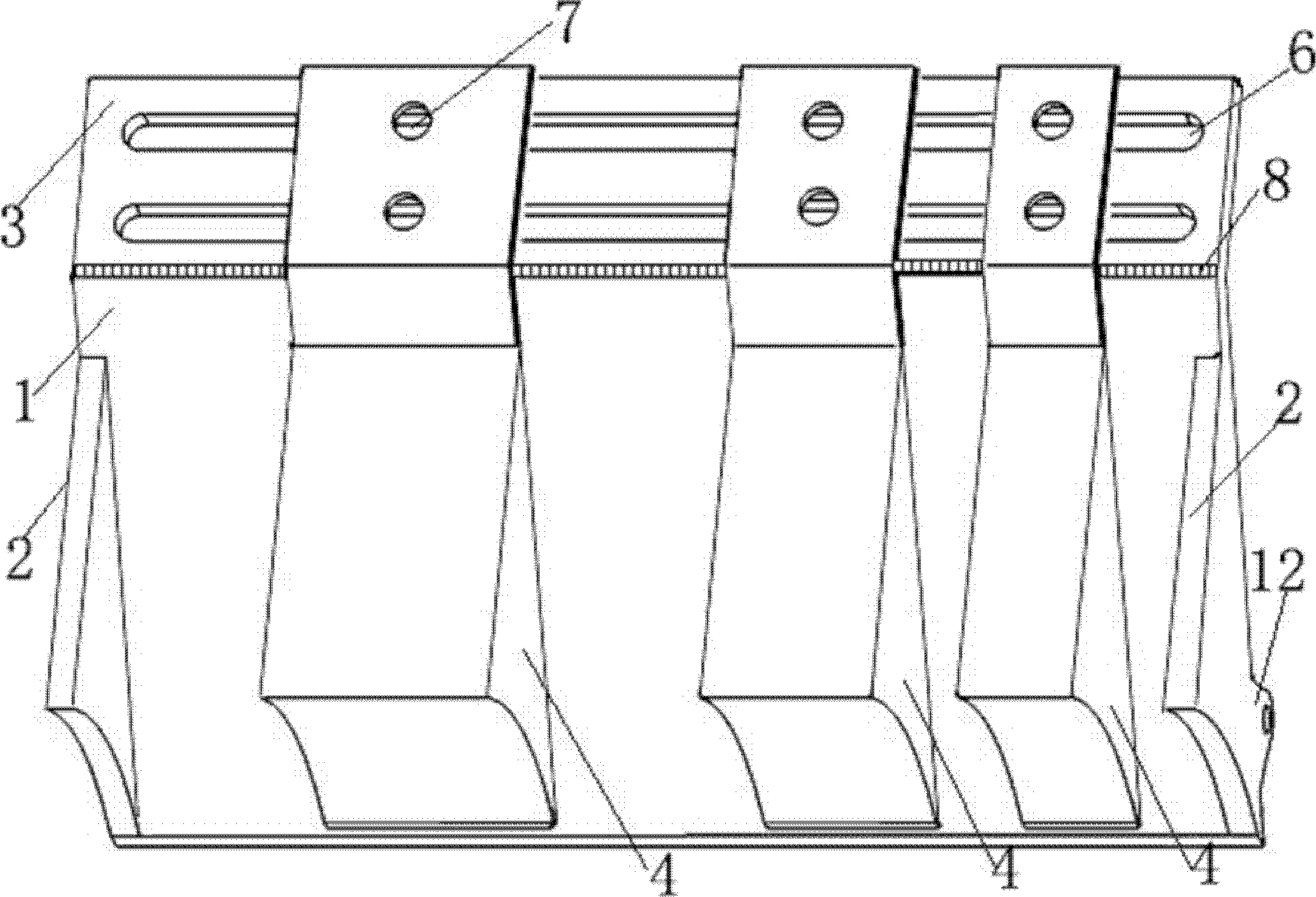

[0056] Such as figure 2 and image 3 As shown, the difference between this implementation and Example 1 is that the top of the rubber pad 5 and the arc partition 4 are sealed and fixed through the cooperation of bolts and washers, and the thickness of the ink tank partition is 32mm, 15mm, and 10mm from left to right. , the inclination angle between the contact slope 1 and the working platform 3 is 150°, and the side of the rubber strip 10 close to the arc end of the arc partition 4 is 5mm higher than the other side of the rubber strip 10. The ink tank is divided into four parts: 1: 1: 2: 2. After the assembly is completed, put red, yellow, cyan and magenta inks (from left to right) in the 4 spaces separated by the ink tank partition, and start A machine that prints several colored lines on a substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com