Double-headed tapping clamp

A tapping and fixture technology, which is applied in the field of tapping fixtures, can solve the problem of low repeat positioning accuracy of blanks, and achieve the effects of decentralized processing, overcoming processing errors, and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The working principle of this technology will be further described below with the accompanying drawings.

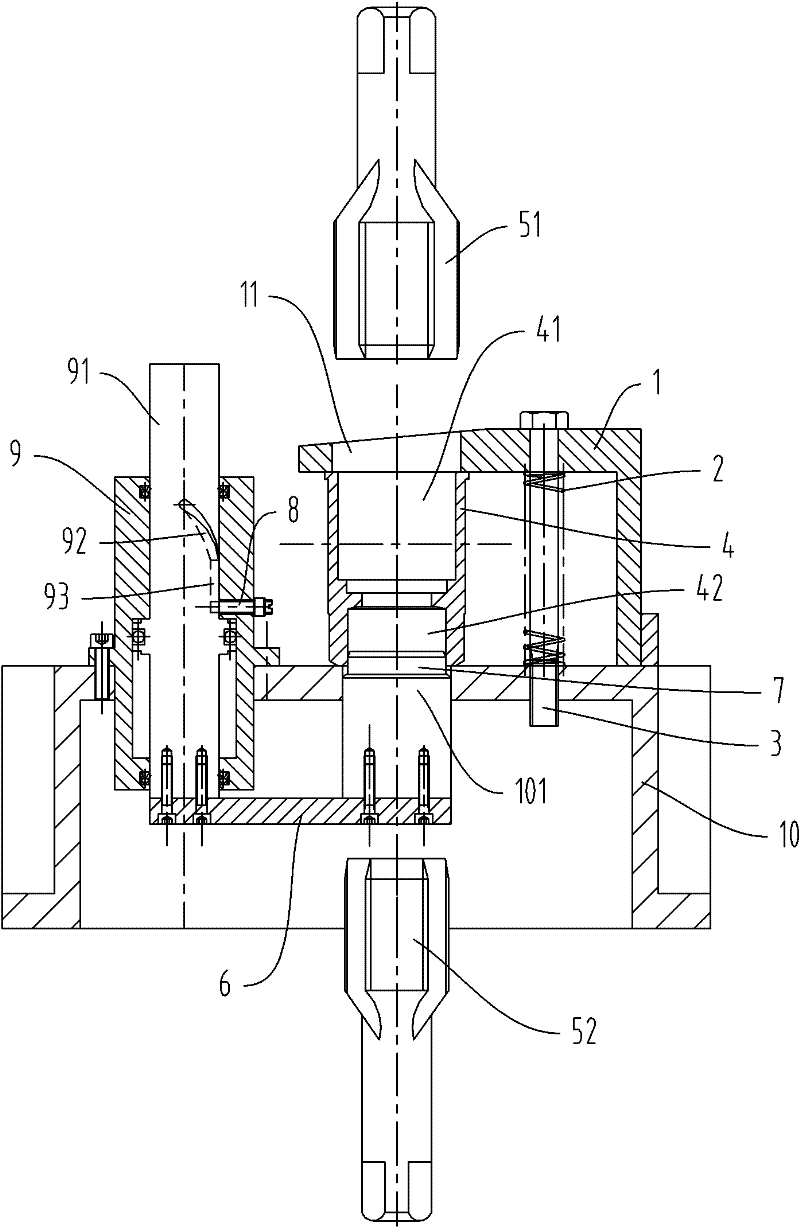

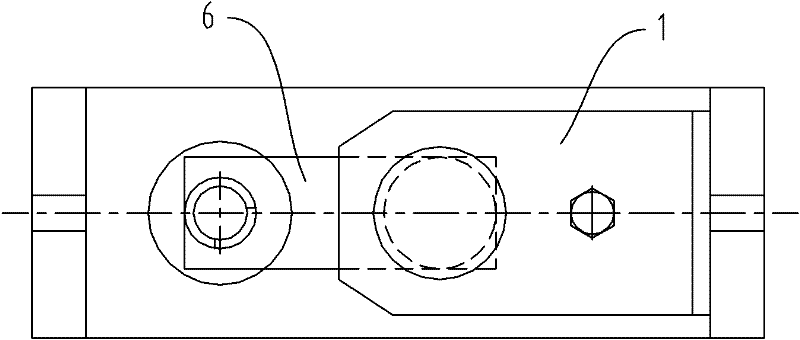

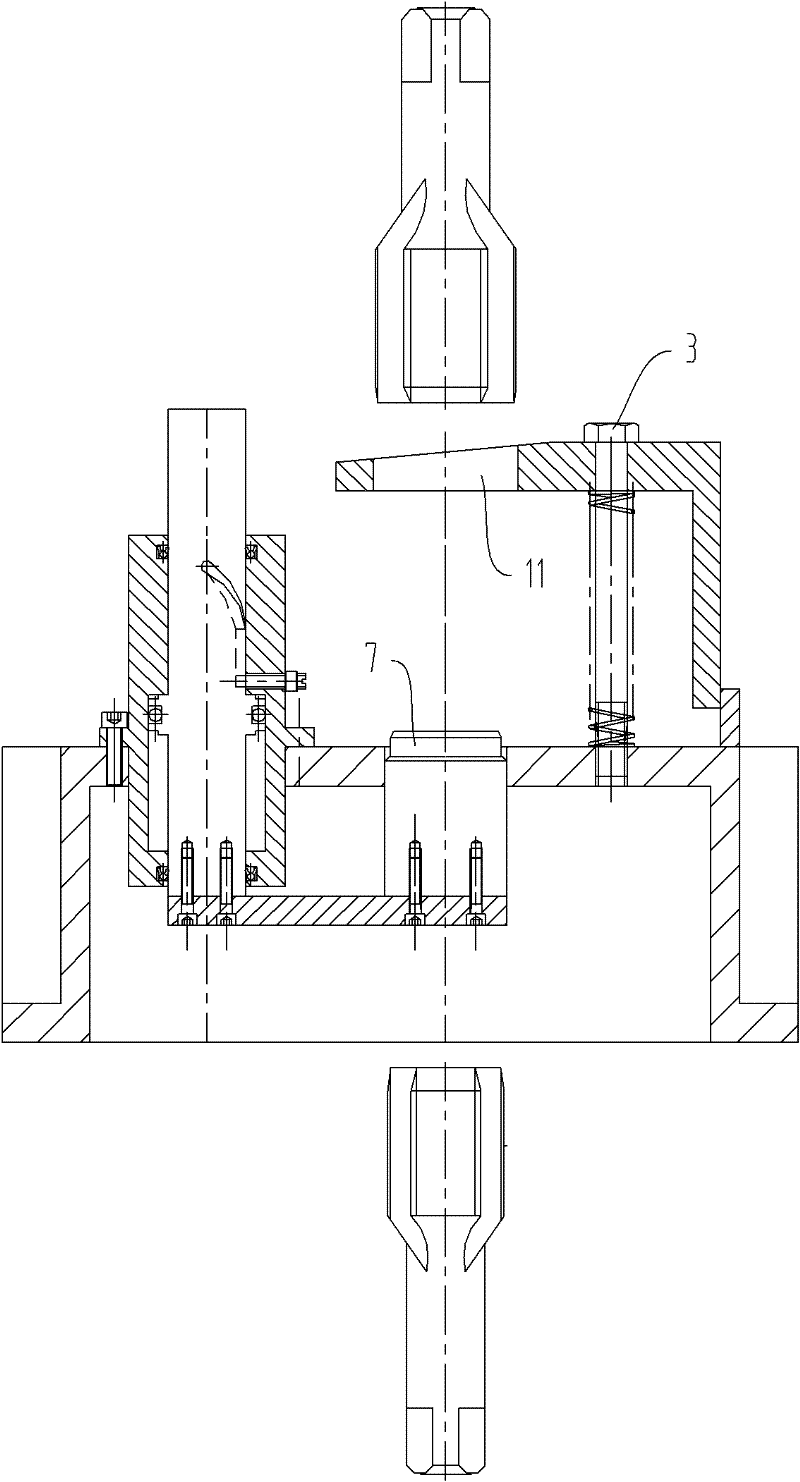

[0017] see figure 1 , 2 The shown double-head tapping fixture includes a clamp body 10, a pressing plate device arranged on the clamp body for clamping a workpiece to be tapped on the clamp body, and an up-down and horizontal driving device.

[0018] The pressing plate device comprises a pressing plate 1, a pressing screw 3 and a spring 2 sleeved on the pressing screw. Have lower through hole 101 on clamp body, have upper through hole 11 on pressing plate, the diameter of upper through hole is all greater than the major diameter of the screw tap 51 of tapping the upper inner hole of workpiece, the diameter of lower through hole is greater than that of workpiece. The major diameter of the screw tap 52 of the lower inner hole tapping. When the workpiece 4 is clamped on the clamp body by the clamping plate device, the upper inner hole 41 of the upper end of the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com