A device, system and method for testing membrane separation performance

A membrane separation and detection device technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problem that the membrane and membrane shell to be tested cannot be reused, continuous sample injection and analysis cannot be performed, and the number of membranes to be measured at one time is limited. and other problems, to achieve the effect of simple casting and installation methods, improved test efficiency, and reduced test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

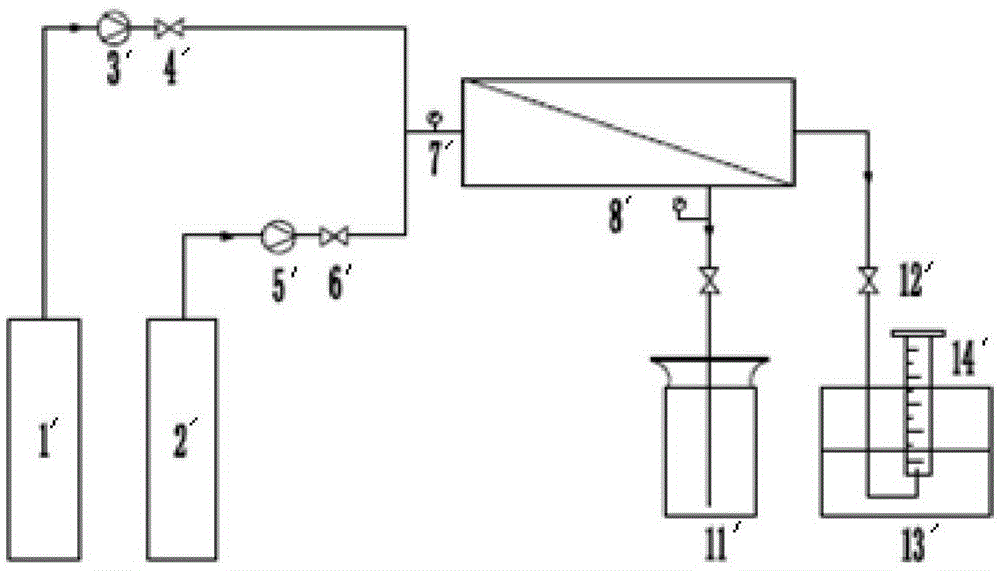

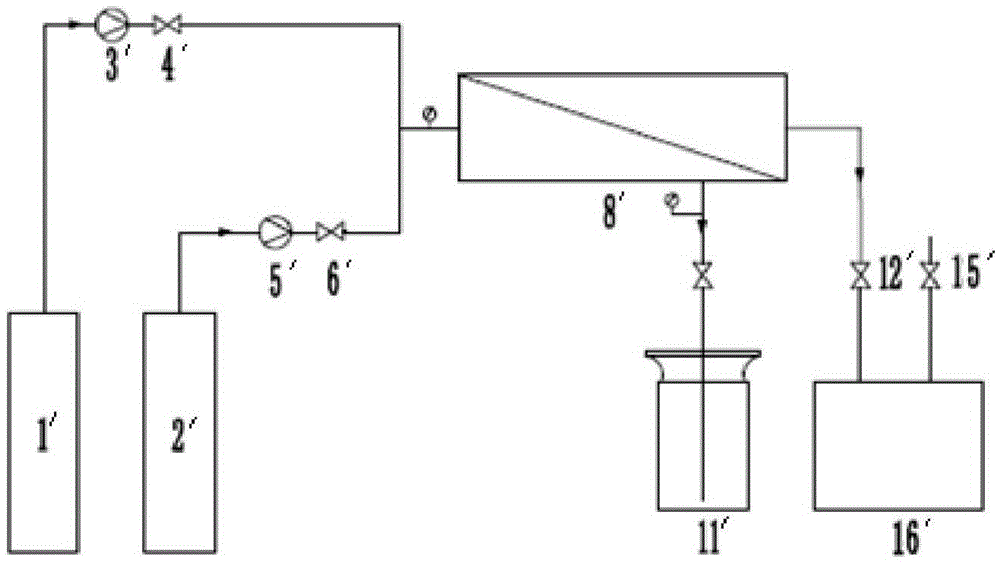

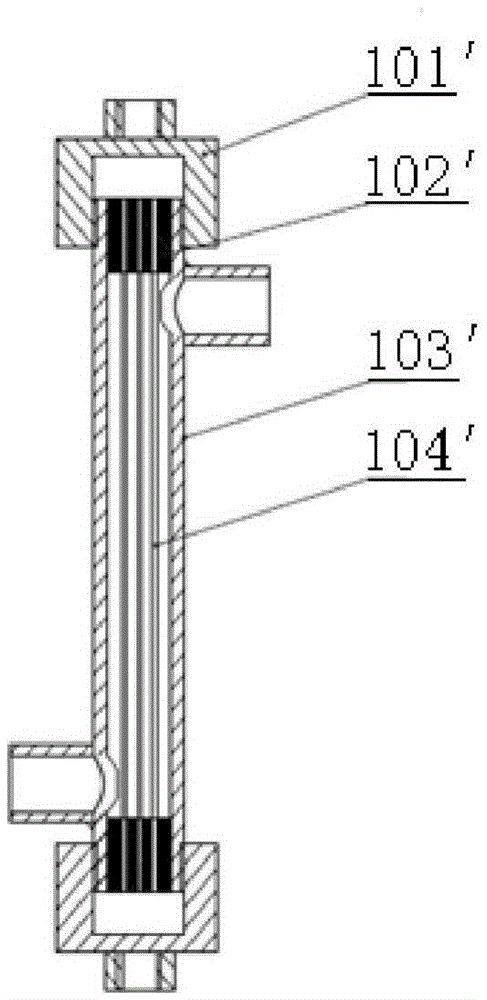

[0067] This embodiment is completed sequentially according to the following steps: Step 1: In this example, the membrane module to be tested is an internal pressure type, and the membrane area is 40cm 2 . according to Figure 4 Connect the raw material gas inlet and outlet of the membrane measuring device, the permeate gas outlet, and the sweeping gas outlet to the corresponding positions in the membrane measuring system; step 2: open the carrier gas cylinder (in this embodiment, H 2 , the purity reaches 99.999%), the filter pressure reducing valve on the steel cylinder reads 0.01MPa, turn on the gas chromatograph, and preheat for 1 hour; Step 3: After filling the humidification tank with water, turn on the heating button of the humidification tank, and adjust the temperature to 45°C. Until the value is stable; Step 4: Open the raw gas cylinder (use CO in this example 2 / N 2 Mixed gas, the ratio of the two is 20:80, the purity reaches 99.9%), adjust the feed gas flow regula...

Embodiment 2

[0069] This embodiment is completed successively according to the following steps: Step 1: In this example, the membrane module to be tested is an external pressure type, and the membrane area is 106 cm 2 . The feed gas inlet and outlet are two short pipes on the side wall of the membrane shell in the membrane measuring device, and the permeate gas outlet is Figure 4 There are 14 medium pressure gauges, and the purge gas inlet is Figure 4 Middle pressure gauge 12; Step 2: Open the carrier gas cylinder (in this example, use H 2 , the purity reaches 99.999%), the filter pressure reducing valve on the steel cylinder reads 0.01MPa, turn on the gas chromatograph, after preheating for 1 hour, the chromatograph reaches 150°C and the temperature is constant; Step 3: After filling the humidification tank with water, turn on the humidification Tank heating button, adjust the temperature to 45 ° C until the value is stable; step 4: open the raw gas cylinder (in this embodiment, CO 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com