Open test device for thermal protector

A thermal protector and testing device technology, applied in the field of mechanical manufacturing and processing, can solve problems such as low production efficiency and affect the overall operation of equipment, and achieve the effects of improving work efficiency, ingenious design, and broad market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

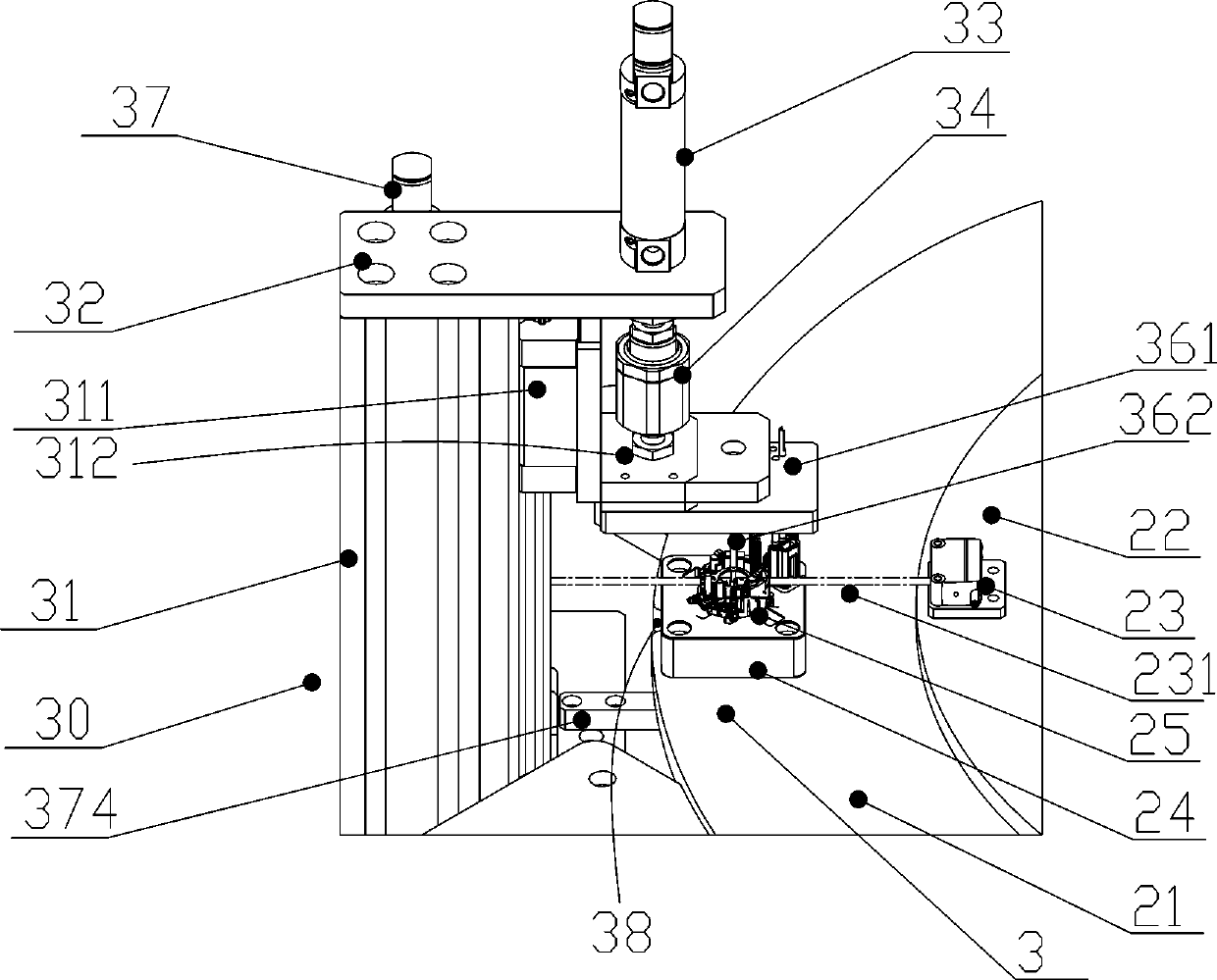

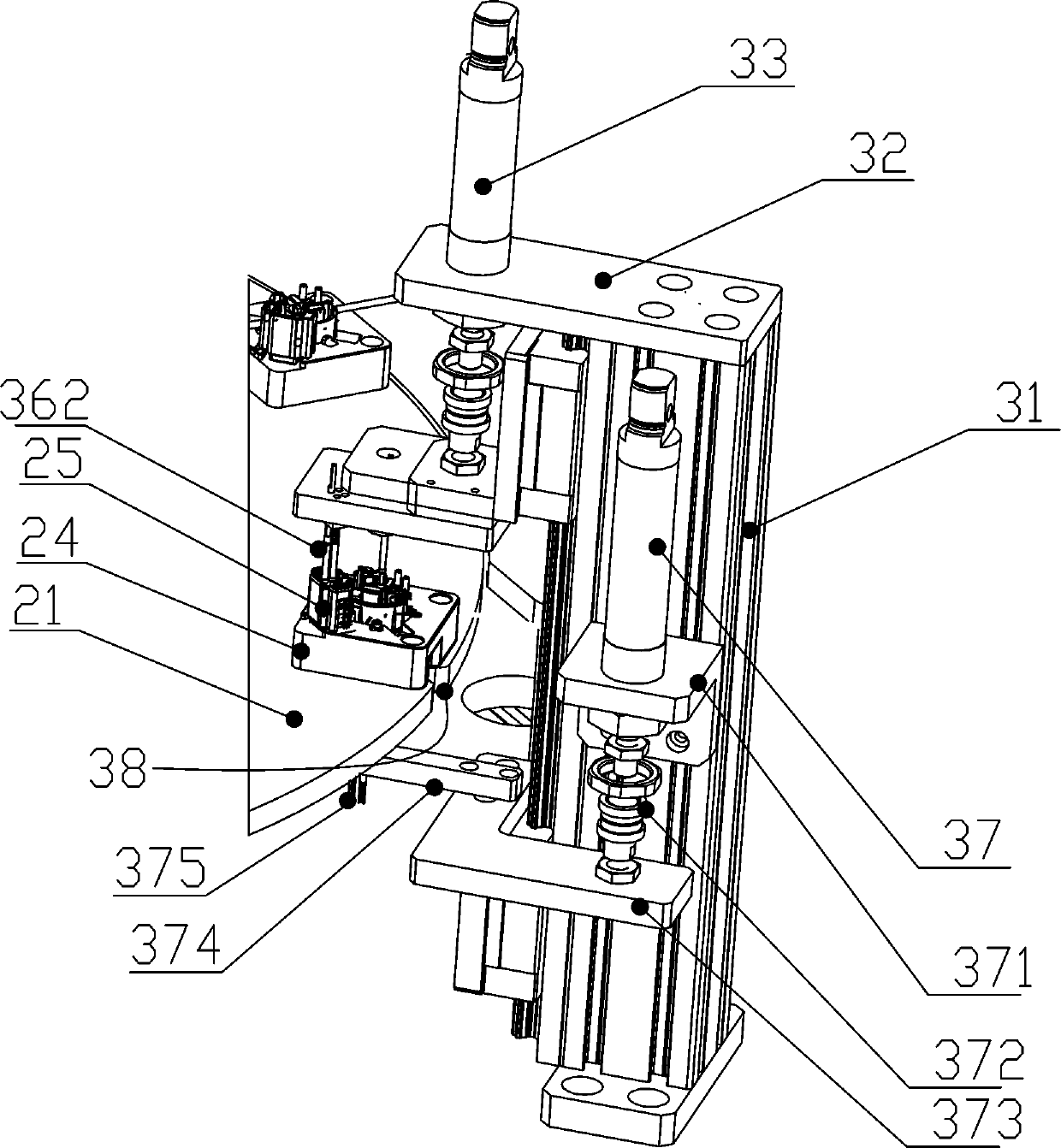

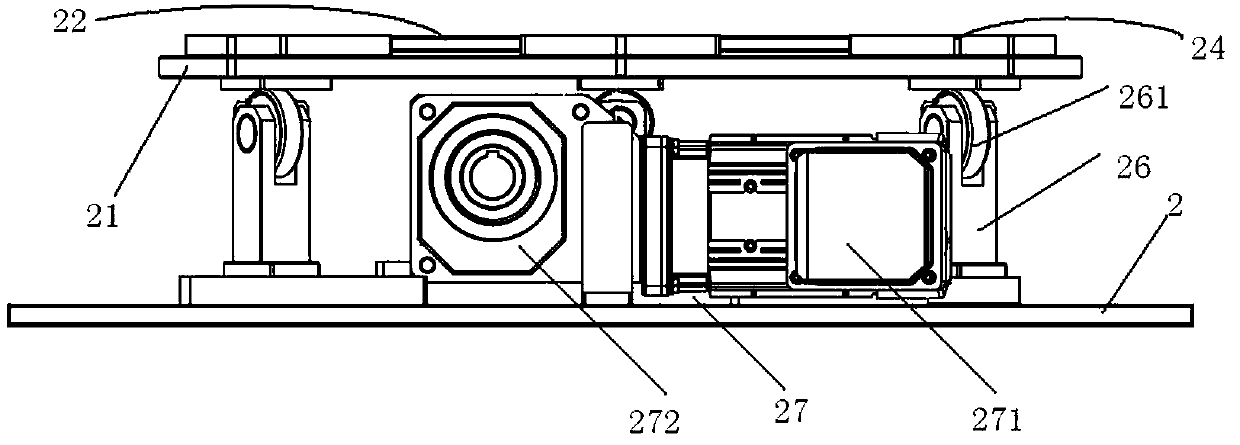

[0022] like Figure 1~Figure 4 As shown, it is a thermal protector opening test device of the present invention, which includes a thermal protector opening test device 30 installed on the workbench 2. The workbench 2 is provided with a turntable mechanism, and the turntable mechanism includes a The driving motor 27, the driving motor 27 includes a motor 271, a divider mechanism 272 electrically connected to the motor 271, the divider mechanism 272 is used for precise positioning, and the turntable mechanism also includes an auxiliary support arranged on the workbench 2 for supporting the turntable 21 Rod 26, auxiliary support rod 26 is pivotally connected with auxiliary runner 261; Workbench 2 is provided with a turntable 21 driven by a drive moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com