Method for testing and loading wafer cassettes

A wafer box and crystal-carrying technology, which is applied in semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., can solve problems such as time waste, achieve the effect of improving production efficiency and ensuring test continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

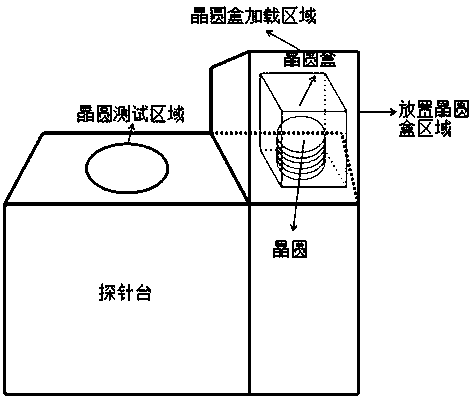

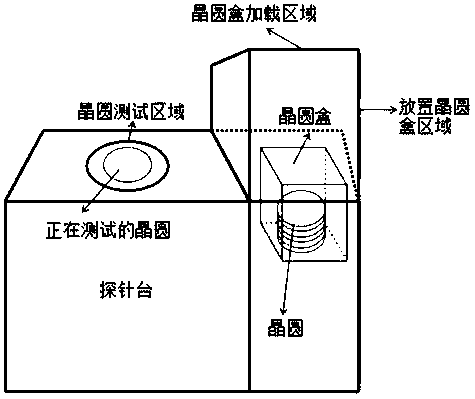

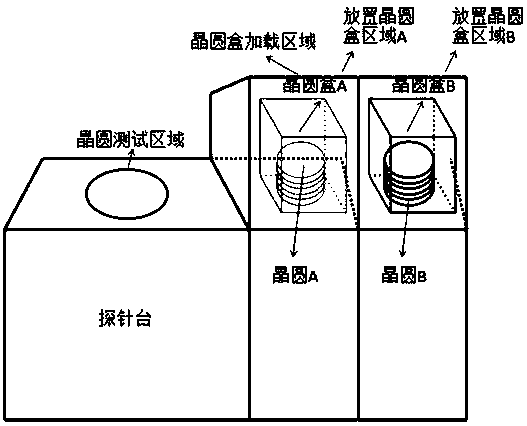

[0014] image 3 It is a schematic diagram of the structure of the wafer cassette probe station loaded in the present invention. The probe station has a special area for placing the wafer cassette, which is increased from one storage area to two storage areas A and B, and the two wafer cassettes A and B are respectively placed on the Wafer cassette rest area A and wafer cassette rest area B are to be tested; if the probe station selects wafer cassette A to test first, as shown in 4, the schematic diagram of the probe station testing wafer cassette A, under wafer cassette A After sinking into the test area for testing, the wafer box B still stays in the wafer box shelving area B. When all the wafers in the wafer box A are tested, the wafer box A is put back to the wafer box shelving area A , load the wafer box B placed in the wafer box rest area B to the test area, such as Figure 5 The schematic diagram of the probe station testing the wafer box B is shown. When the wafer box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com