Electric de-dusting purifying device for phosphorus-making furnace gas

A technology of purification device and electrostatic precipitator, which is applied in the direction of combination device, phosphorus compound, inorganic chemistry, etc., can solve the problems of inability to apply multi-electrode phosphorus electric furnace device, electrostatic precipitator cannot work normally, high operation and maintenance costs, and achieve Maintain the high efficiency of dust removal, solve the difficulty of dust removal and ash discharge, and reduce the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

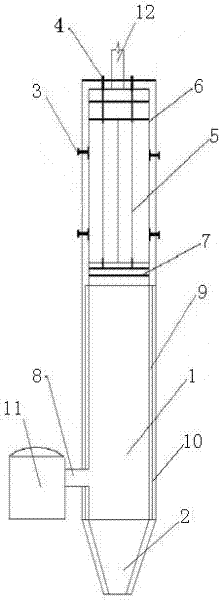

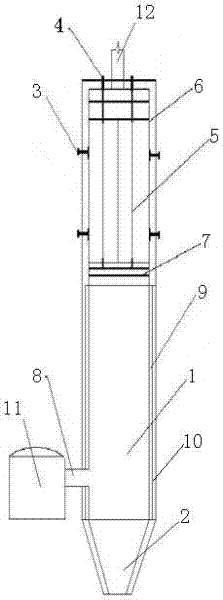

[0038] A gas-electric dust removal and purification device for a phosphorus-making furnace, the structure of which device includes:

[0039] Heating pretreatment device housing 1—the device housing is a cylindrical cylinder with a tapered bottom and a dust outlet 2; a flange connected to the electrostatic precipitator is provided on the top of the cylinder;

[0040] Electrostatic precipitator - the device includes: an anode vibrator 3 arranged on the side wall of the device casing, a cathode high voltage device 4 arranged on the top cover of the device casing, connected with the cathode high voltage device, and vertically located in the device casing The corona electrode 5 fixed by the cathode hanger is located at the dust collection electrode 6 of the device housing;

[0041] Furnace gas flow distribution plate 7—the air flow distribution plate is an orifice horizontally located at the lower part of the shell of the electrostatic precipitator;

[0042] Air guide pipe 8—the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com