Disc vacuum filter with independent adsorption system and independent dewatering system

A vacuum filter, disc type technology, applied in filtration and separation, mobile filter element filters, chemical instruments and methods, etc., can solve the problems of overloaded stop of the stirring shaft, increased enterprise cost, uneven slurry concentration, etc. Stable, energy-saving, and unbreakable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

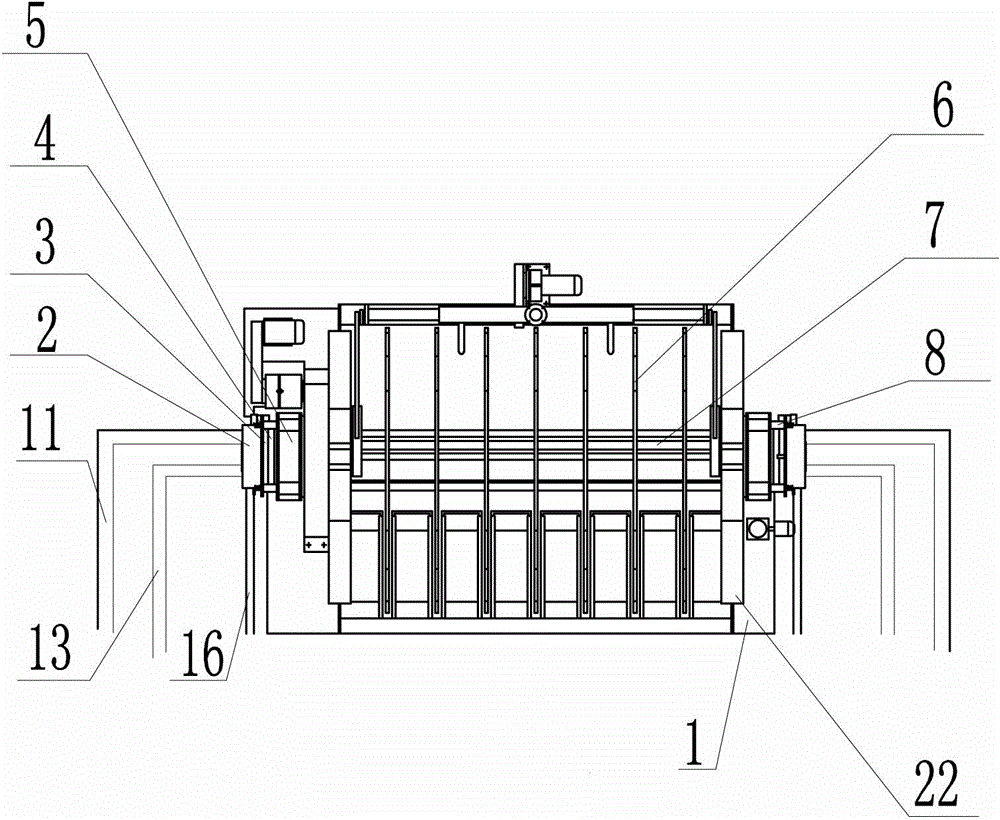

[0033] Such as figure 1 , 2 As shown, a disc vacuum filter with independent adsorption and independent dehydration system includes a tank body 1 with an overflow port, a slurry discharge port and a discharge port, and bearing assemblies 5 arranged at both ends of the tank body 1 , the main shaft system 7 arranged between the two bearing assemblies 5, the air discs 4 which are fixed on both ends of the main shaft system 7 and rotate synchronously with the main shaft system 7, are adjacent to the two air discs 4 respectively Two fixed distribution head devices connected, a group of filter discs 6 arranged on the main shaft system 7, a stirring device 22 arranged in the tank body 1, and a transmission mechanism connected with the main shaft system 7.

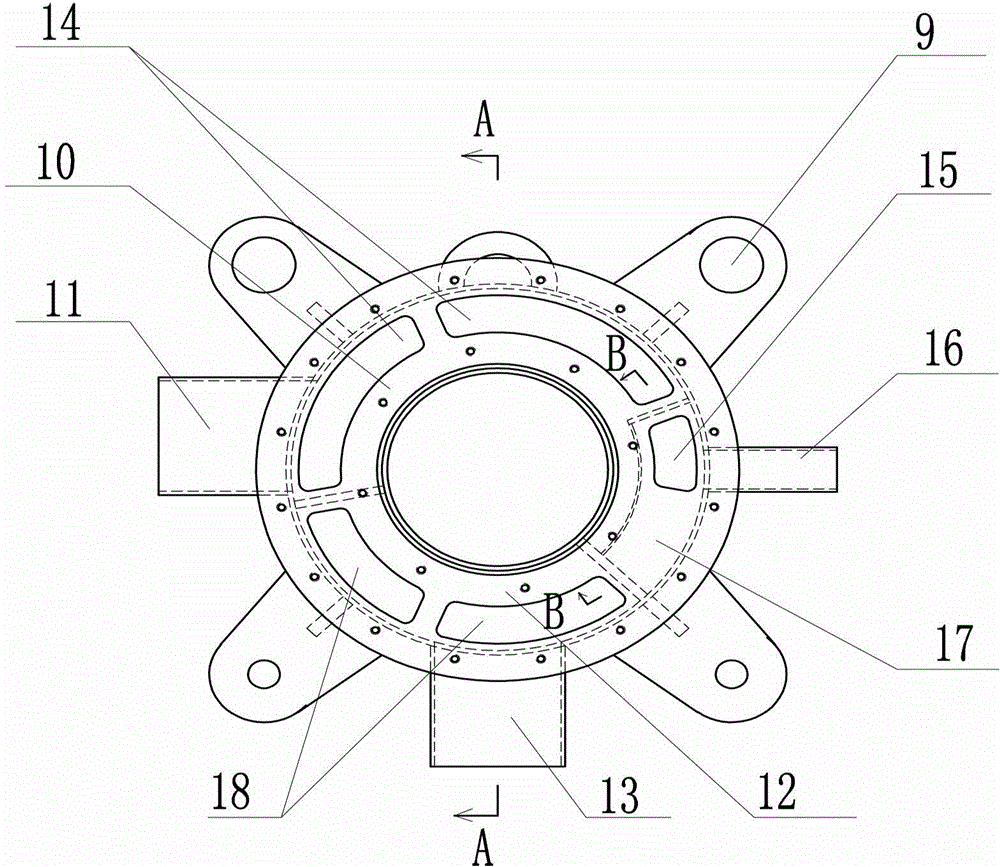

[0034] Such as figure 1 , 3 , 4, and 5, it is characterized in that the fixed d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com