Washing machine

A technology of stem washing machine and stem washing plate, which is applied in the field of stem washing machine, can solve the problems of water not meeting the process requirements, affecting the quality of shredded stems, and high foam content of shredded stems, achieving compact structure and increasing soaking time , The effect of reducing foam content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

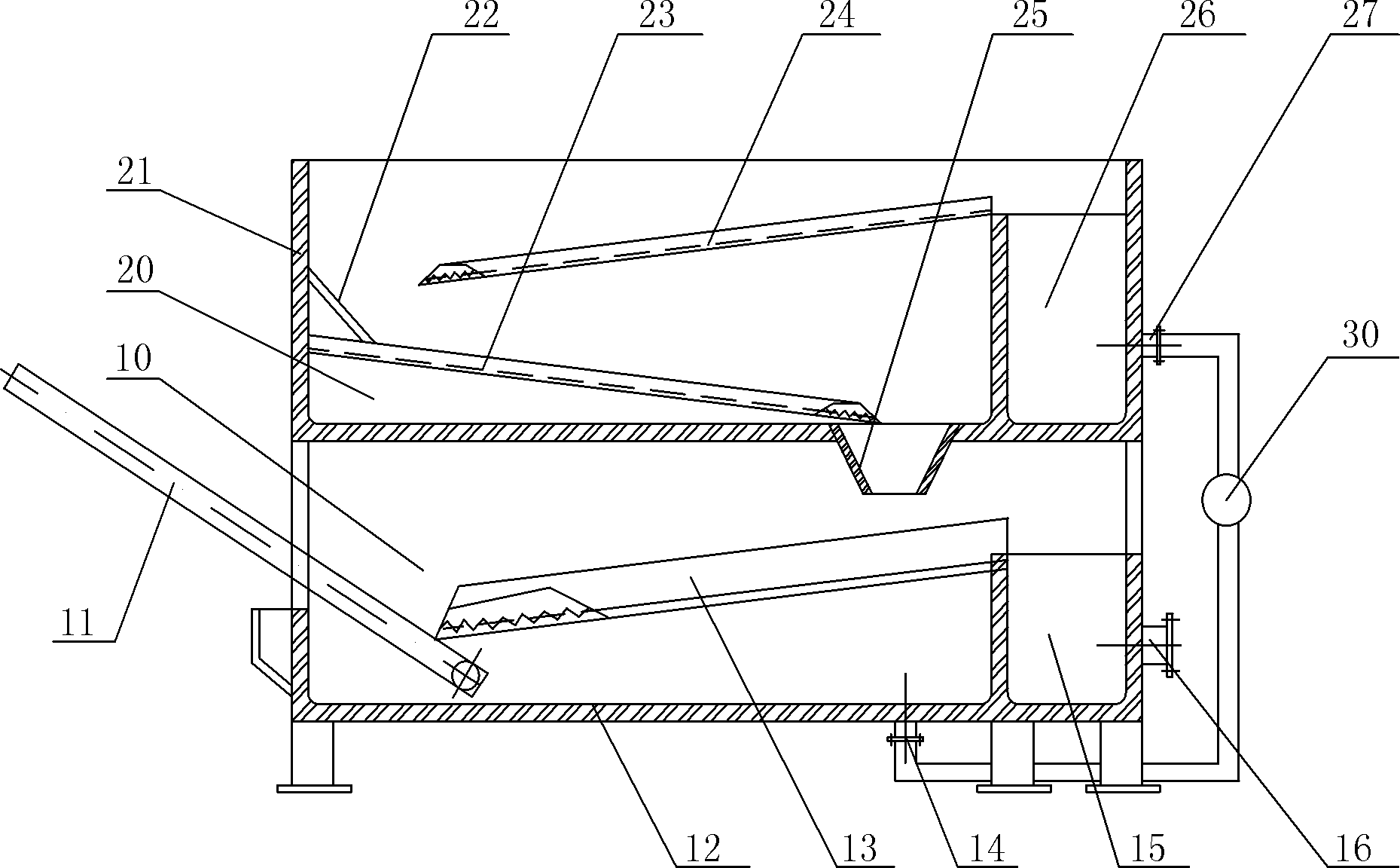

[0016] As shown in the figure, a stem washing machine of the present invention includes a lower moisture regain box 10, the lower moisture regain box 10 includes a discharge mesh belt 11, a lower box body 12, a water tank 13 and an overflow water tank 15, and the overflow water tank 15 is provided with a water inlet 16. The bottom of the lower box 12 is provided with a drain port 14. The cross-section of the water tank 13 is U-shaped, and the bottom is provided with a corrugated plate. The structure of this part is the same as that of the existing stem washing machine, and the specific structure will not be repeated.

[0017] The present invention is also provided with an upper moisture regain box 20 above the lower moisture regain box 10. The upper moisture regain box 20 includes an upper box body 21, a first stem washing plate 24, a second stem washing plate 23 and a water storage tank 26. The water storage tank 26 is provided with The upper water port 27 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com