Rooting agent for softwood cutting propagation of elms

A technology of twig cutting and rooting agent, which is applied in the field of twig cutting and seedling propagation of excellent Ulmaceae species, can solve the problems of disease resistance, poor disease prevention ability, long rooting treatment time, and unsatisfactory rooting rate, etc. Increased rooting rate, reliable and stable effect, and increased survival rate of cuttings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Rooting agent raw material formula (preparation of 1000ml rooting agent raw material dosage):

[0019] Indole butyric acid 600mg, 2,4-dichlorophenoxyacetic acid 15mg, boric acid 10mg, potassium permanganate 4000mg, 95% ethanol 110ml, water to 1000ml.

[0020] Preparation method: Use 110ml of 95% ethanol to dissolve the two components of indole butyric acid and 2,4-dichlorophenoxyacetic acid, and then dissolve boric acid and potassium permanganate in water; Mix, add water to make up to 1000ml, stir evenly, seal and store away from light. For long-term storage, it should be placed in a low temperature environment of 5±2°C. In practical application, the base of elm twig cuttings can be directly dipped with the above stock solution, and the dipping time is 1 second. When the solution is prepared and used, metal containers cannot be used, only plastic or ceramic containers other than metal can be used.

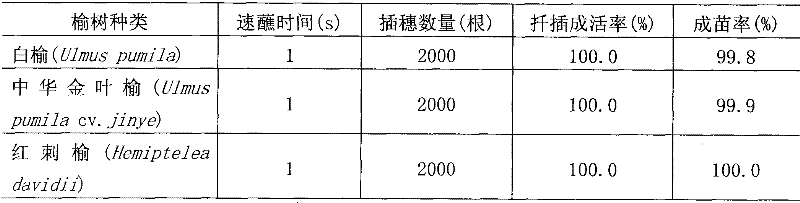

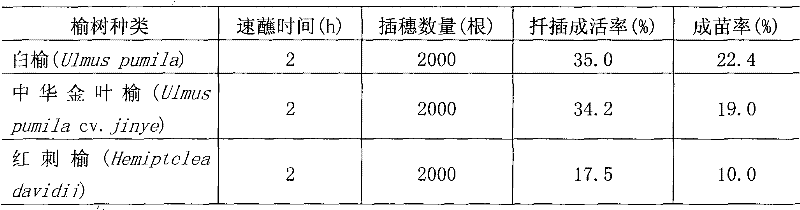

[0021] Listed below is a comprehensive example of the application of...

Embodiment 2

[0027] The proportioning of each component of rooting agent is:

[0028] Indolebutyric acid 650mg, 2,4-dichlorophenoxyacetic acid 20mg, boric acid 15mg, potassium permanganate 3500mg, 95% ethanol 120ml, water to 1000ml.

[0029] When preparing, first use 120ml of 95% ethanol to dissolve indole butyric acid and 2,4-dichlorophenoxyacetic acid, then dissolve boric acid and potassium permanganate with water, then mix the above components and add water to dilute to 1000ml, stir evenly, seal and store away from light. The bases of semi-lignified twig cuttings of Ulmus chinensis, Ulmus sinensis and Ulmus chinensis were dipped directly with the above stock solution. The dipping time was 2 s, and the survival rates of cuttings were 100.0%, 99.8% and 99.4%, respectively.

Embodiment 3

[0031] The proportioning of each component of rooting agent is:

[0032] Indolebutyric acid 700mg, 2,4-dichlorophenoxyacetic acid 10mg, boric acid 10mg, potassium permanganate 3000mg, 95% ethanol 120ml, water to 1000ml.

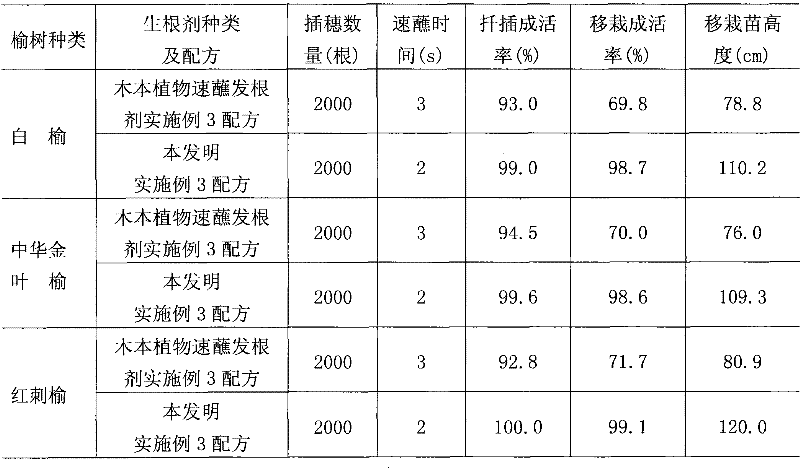

[0033] Using the same preparation method as in Example 1, directly use the above-mentioned rooting agent stock solution to quickly dip the bases of the cuttings of Ulmus chinensis, Ulmus chinensis and Ulmus chinensis, the dipping time is 2s, and the survival rates of cuttings are 99.0% and 99.6% respectively. and 100.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com