Eutectic welding machine for die bonding of LED (Light Emitting Diode) chip

A LED chip and eutectic soldering technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as chip thermal damage, chip function failure, and large temperature balance error of the heating system, so as to achieve thermal damage Small, the effect of ensuring wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

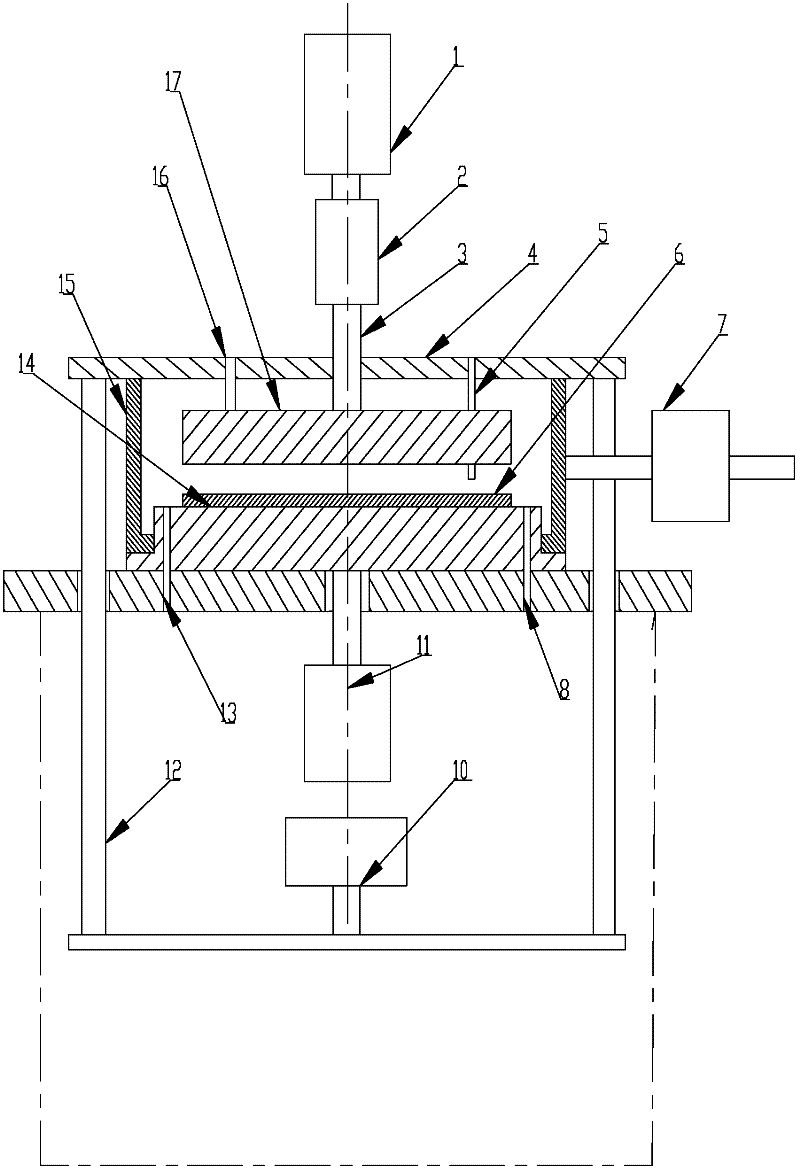

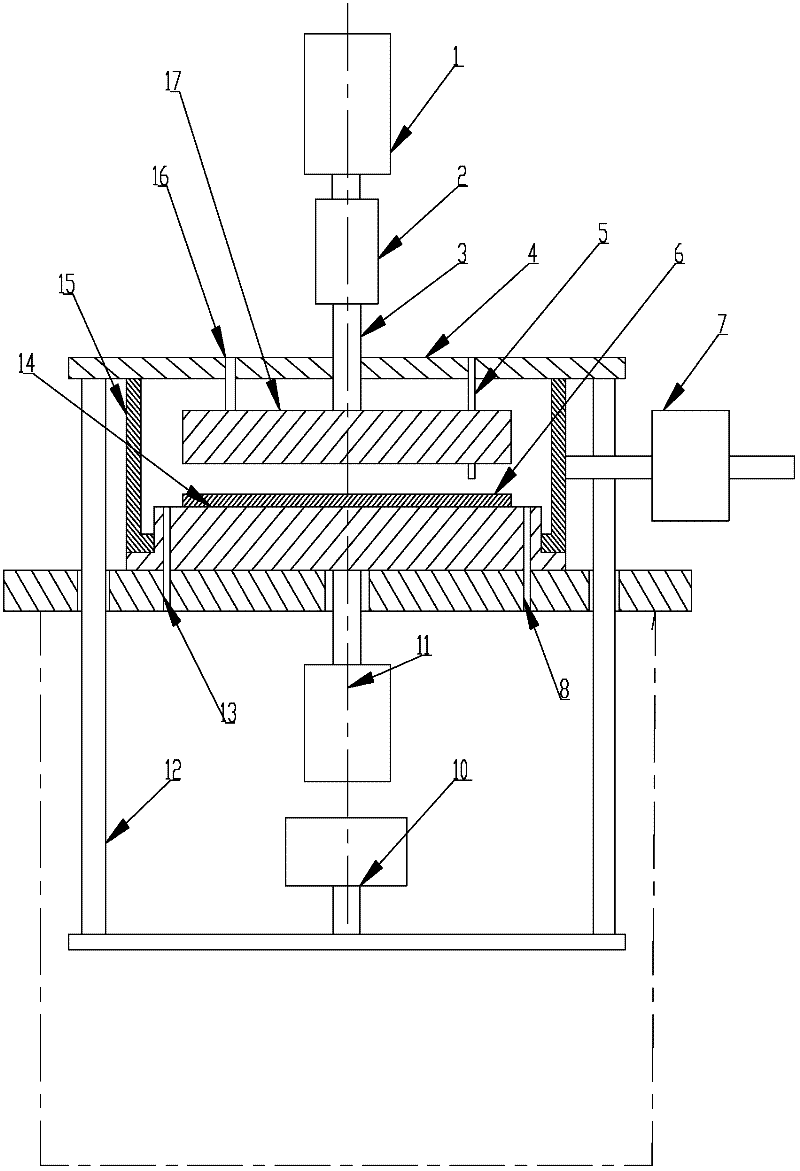

[0026] Such as figure 1 As shown, a eutectic welding machine for LED chip solidification, including a eutectic tray 15, a targeting heating plate 14, a sealing plate 4, a chip pressing heat conducting plate 17, a resonant transducer 2, and a resonant horn 3. The eutectic tray 15 is used to place the LED chip 6, and is provided with a stepping motor feed mechanism 7 that can drive the eutectic tray 15 to move horizontally. The interface combined with the support is highly directional heated. The targeting heating plate 14 is provided with a heating plate driving cylinder 11, which can be driven by the heating plate driving cylinder 11 to be close to the bottom of the eutectic tray 15, and the sealing plate 4 is arranged above the eutectic tray 15, and the sealing plate 4 passes through the guide The column 12 is connected with the sealed flat cylinder 10, and can be tightly sealed with the upper end of the eutectic tray 15 driven by the sealed flat cylinder 10 to form a close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com