Capacitive touch screen detection device

A capacitive touch screen, a technology to be tested, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of low production efficiency and high production cost, and achieve the effects of good versatility, high reliability connection, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

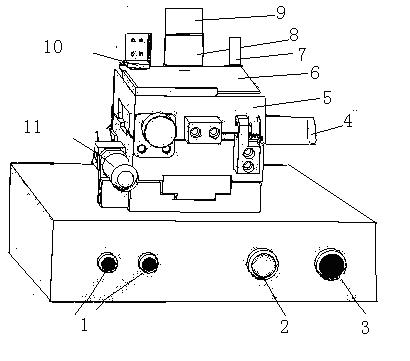

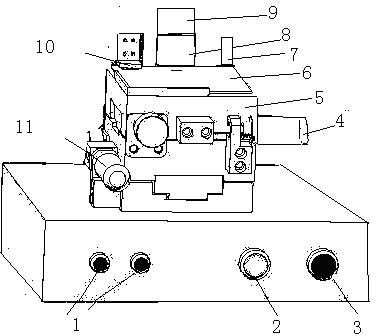

[0010] As shown in the figure, the components of the present invention are as follows: working status indicator light 1, test button 2, power switch 3, X direction adjustment head 4, X\Y fine-tuning platform 5, stage 6, upper camera 7, upper camera display Screen 9, lower camera display screen 8, upper thread needle mounting plate 10, Y direction adjustment head 11.

[0011] A fixed adjustment device for a fine-pitch needle board is provided on the stage, the fine-pitch needle board is connected to the pins of the capacitive touch screen to be detected, and the fine-pitch needle board is electrically connected to the detection circuit.

[0012] The micro-pitch wire needle board is the lead-out wire needle (wire needle) on the insulating board, and the wire needle corresponds to the pin position of the capacitive touch screen to be tested. The wire needle is 2mm higher than the insulation board, which is a single row of metal probes, the surface of which is gold-plated or other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com