Self-aligning permanent magnet magnetic bearing

A magnetic bearing and permanent magnet force technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of difficulty in promotion, external power consumption, and inability to achieve the effect of no energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

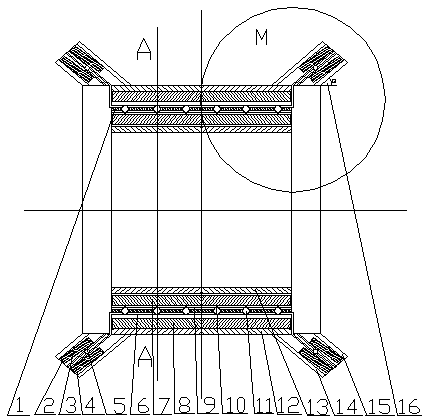

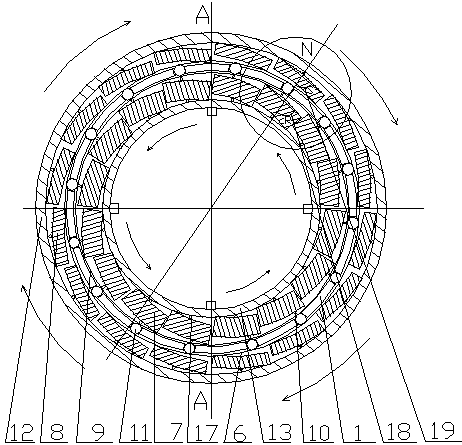

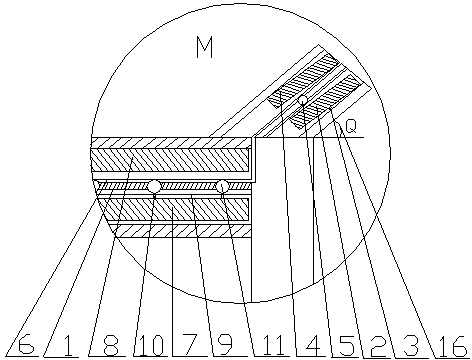

[0024] exist figure 1 There are two implementation structures in the embodiment shown in —7: one is that the permanent magnet block 8 of the outer ring of the bearing is fixed but the angle can be adjusted manually, and the permanent magnet block 7 of the inner ring of the bearing can be pushed by the steel ball between the inner and outer rings to rotate and make The A-type structure in which the magnetic line density changes, and the other is that the permanent magnet block 7 of the bearing inner ring is fixed but can be adjusted manually, and the permanent magnet block 8 of the bearing outer ring can be pushed by the steel ball between the inner and outer rings to rotate and change the magnetic line density Type B structure.

[0025]Type A structure: the bearing inner ring inner barrel 13 of the bearing inner ring and the bearing inner ring outer barrel 9 form an annular interlayer, and the annular interlayer is equipped with a plurality of long tiles or strips that form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com