Automatic stator blade distance adjusting device for vertical roller mill powder concentrator

An automatic adjustment, powder separator technology, applied in the direction of solid separation, separation of solids from solids with air flow, grain processing, etc., can solve the problem of reducing the adaptability of vertical mills to grinding materials, and the adjustment of the distance between static blades is manual Phases, reducing the operating rate of vertical mill equipment, etc., to achieve the effect of ensuring continuous and stable operation, improving equipment operating rate, and low manufacturing and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

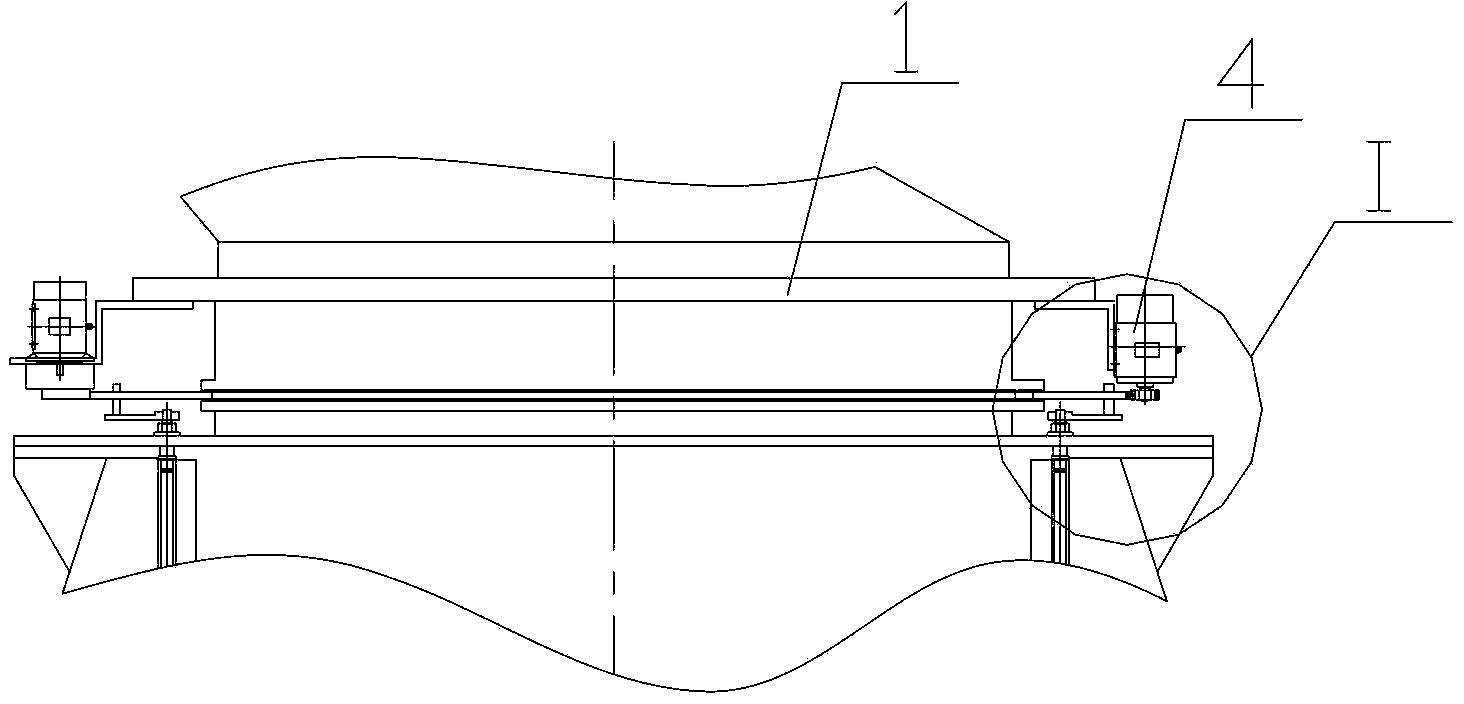

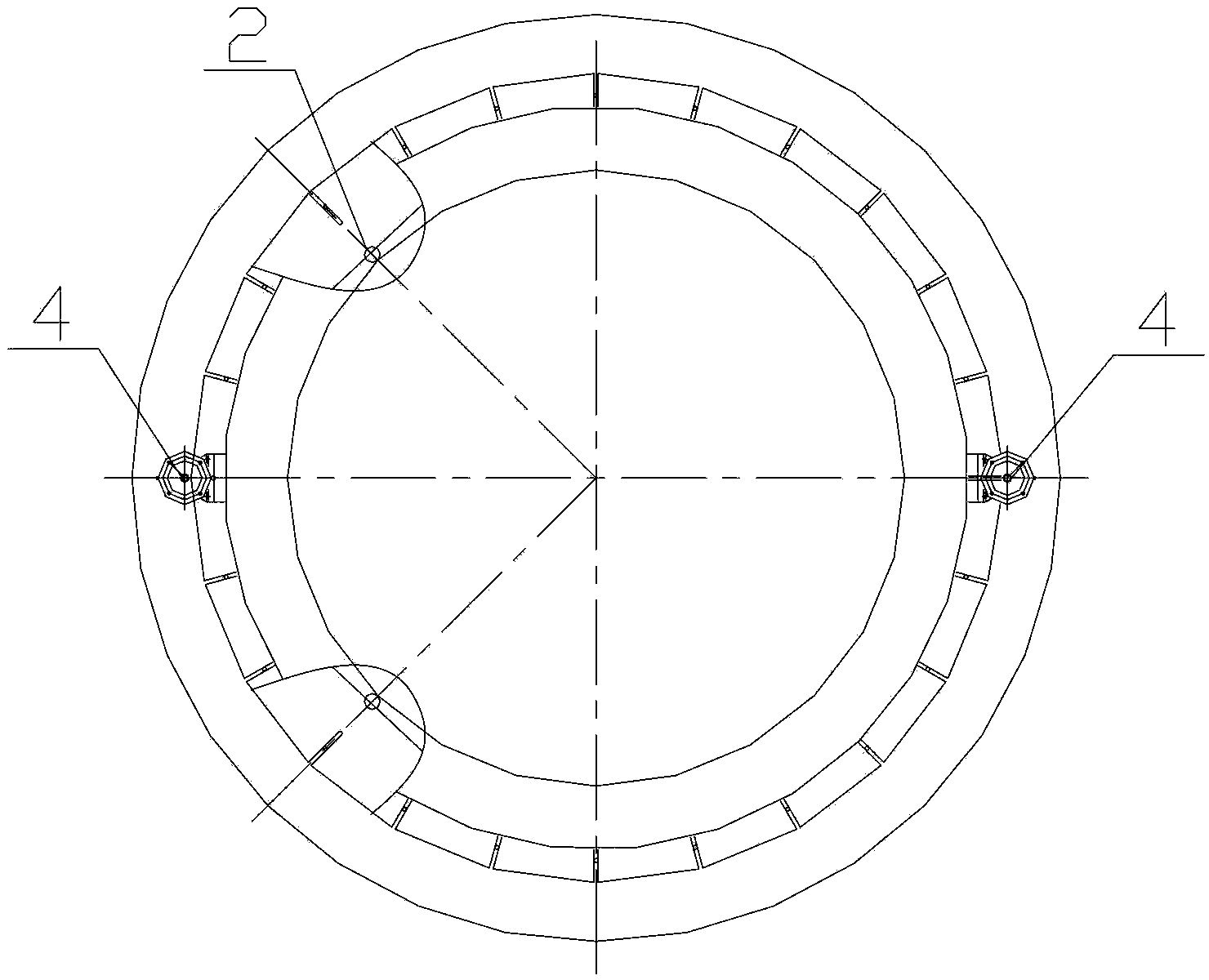

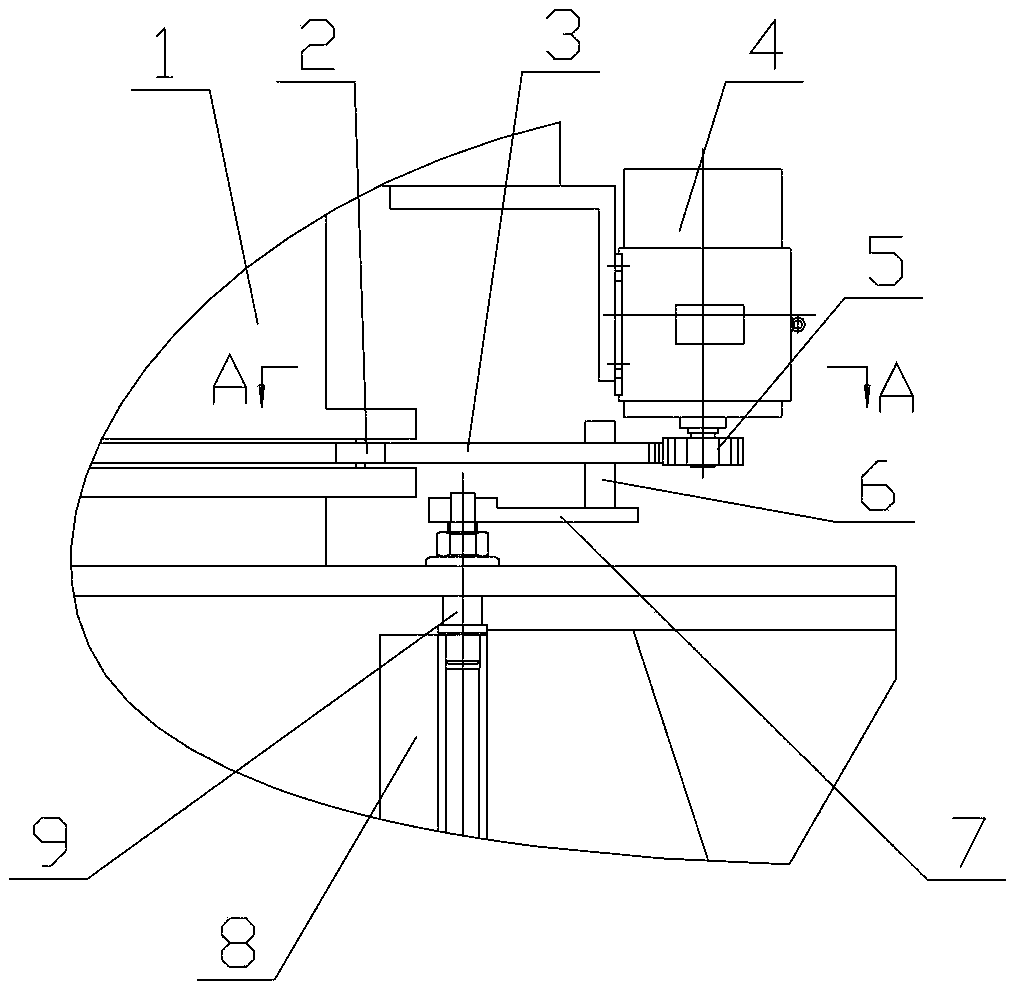

[0012] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0013] See Figure 1 to Figure 4 , an automatic adjustment device for the spacing between stationary blades of a vertical roller mill powder separator, comprising an annular drive disk 3 horizontally arranged at the center of the powder separator housing, and the annular drive disk 3 is provided with a stationary blade 8 of the powder separator. The number of equal and evenly arranged outer notch grooves 10, each of the outer notch grooves 10 is inserted with a pin shaft 6, and the pin shaft 6 is vertically fixed on the horizontal rocker arm 7, and the horizontal rocker arm 7 is connected to the vertical rocker arm 7. The pivot 9 is affixed, and the vertical pivot 9 is affixed to the stationary blade 8 of the powder separator, and the vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com