Test device capable of simulating plugging of high temperature and high pressure dropping strata

A testing device, high temperature and high pressure technology, applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve problems such as low simulation level, lack of reflection, inconvenient analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

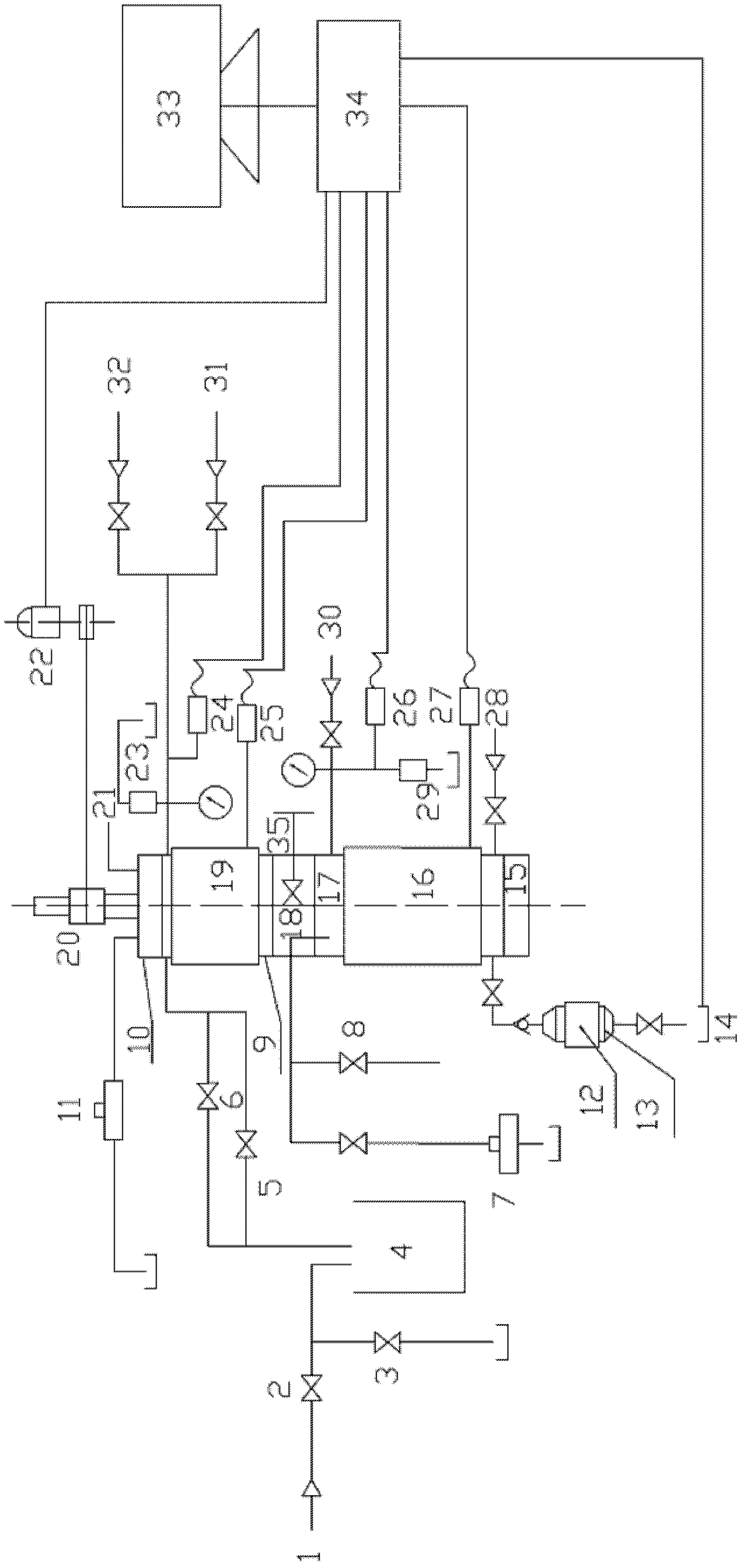

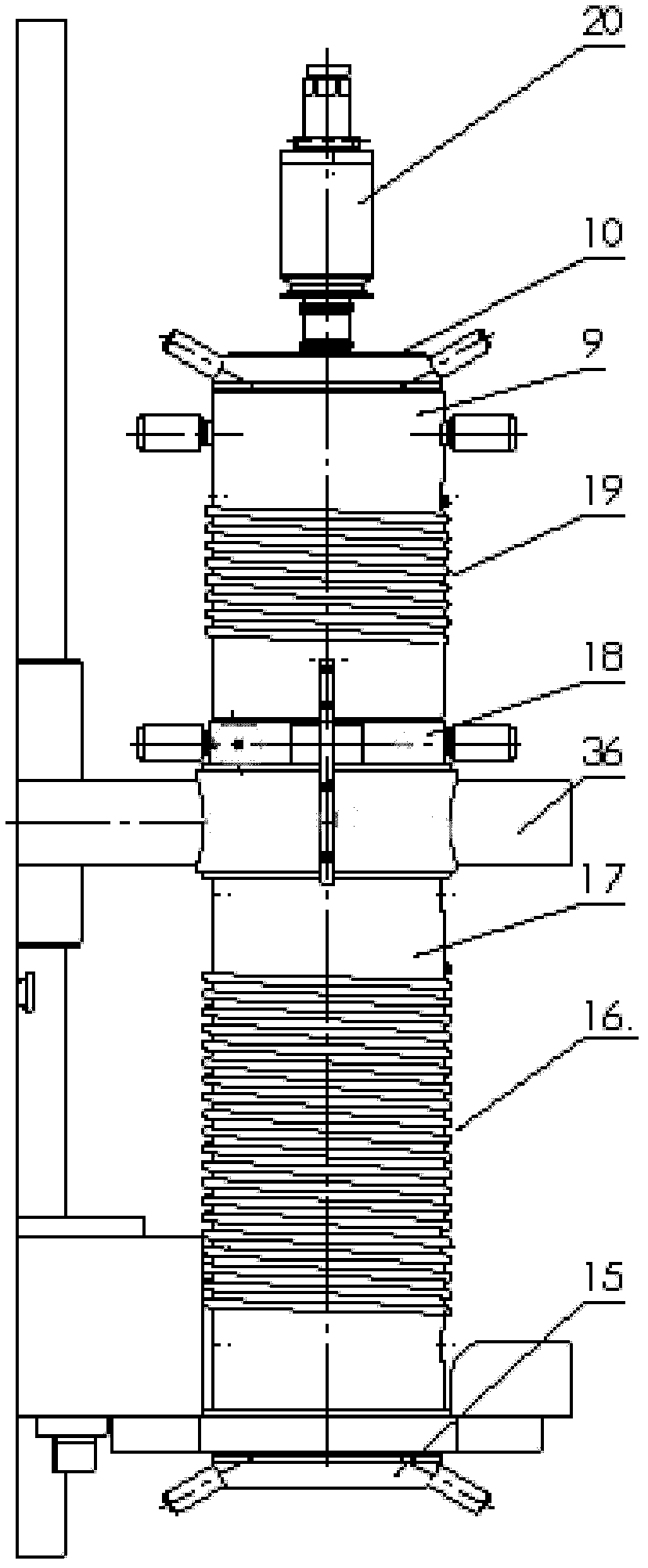

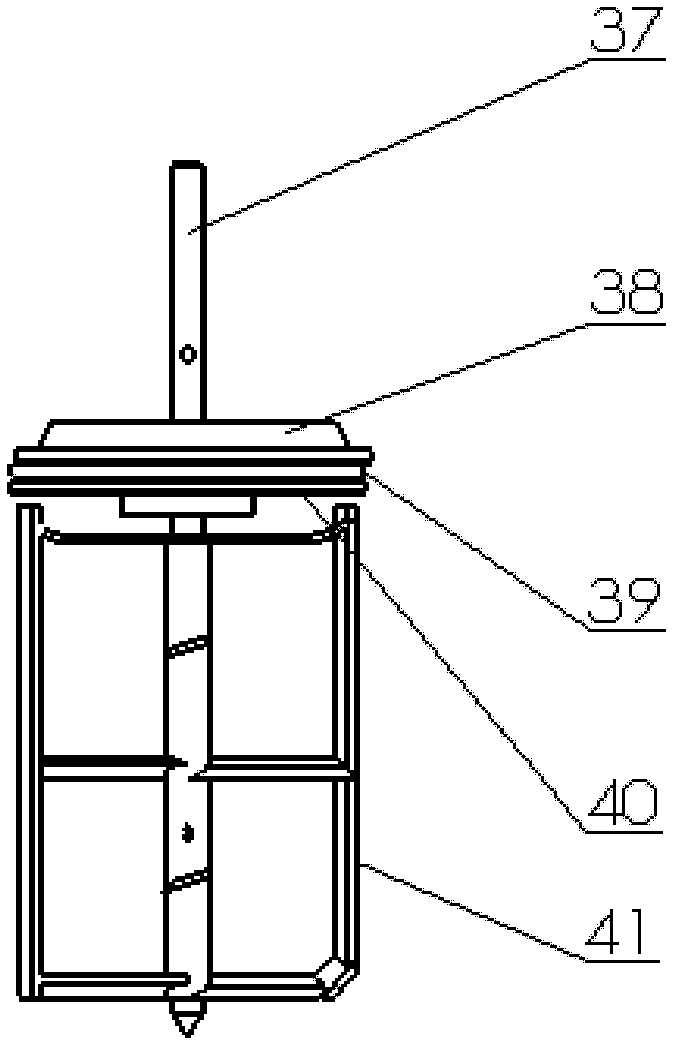

[0029] see figure 1 , figure 2 , image 3 .

[0030] The high temperature and high pressure leakage formation simulation plugging test device mainly consists of a gas source 1, an oil tank 4, an upper kettle body 9, a lower kettle body 17, a water source 28, a magnetic drive 20, a frequency conversion motor 22, a central processing system 34, a data display system 33, an integrated Liquid tank 13 is composed of, it is characterized in that, described upper still body 9 has upper kettle cover 10, upper kettle body heater 19, and lower kettle body 17 has lower kettle cover 15, lower kettle body heater 16, between upper kettle body and lower kettle body There is an intermediate kettle cover 18 and a communication valve 35; the upper kettle body is connected to the fuel tank 4 through the oil inlet valve 5 and is provided with an oil spill observation port 21, the fuel tank 4 is connected to the gas source 1 through the fuel tank inlet valve 2, and the fuel tank is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com