Hybrid hydraulic excavator

A hybrid power and excavator technology, applied in the direction of earth movers/shovels, mechanical equipment, fluid pressure actuating devices, etc., can solve the problems of unreleased energy and difficulty in component installation, and achieve energy reduction and lightening. Effect of load pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

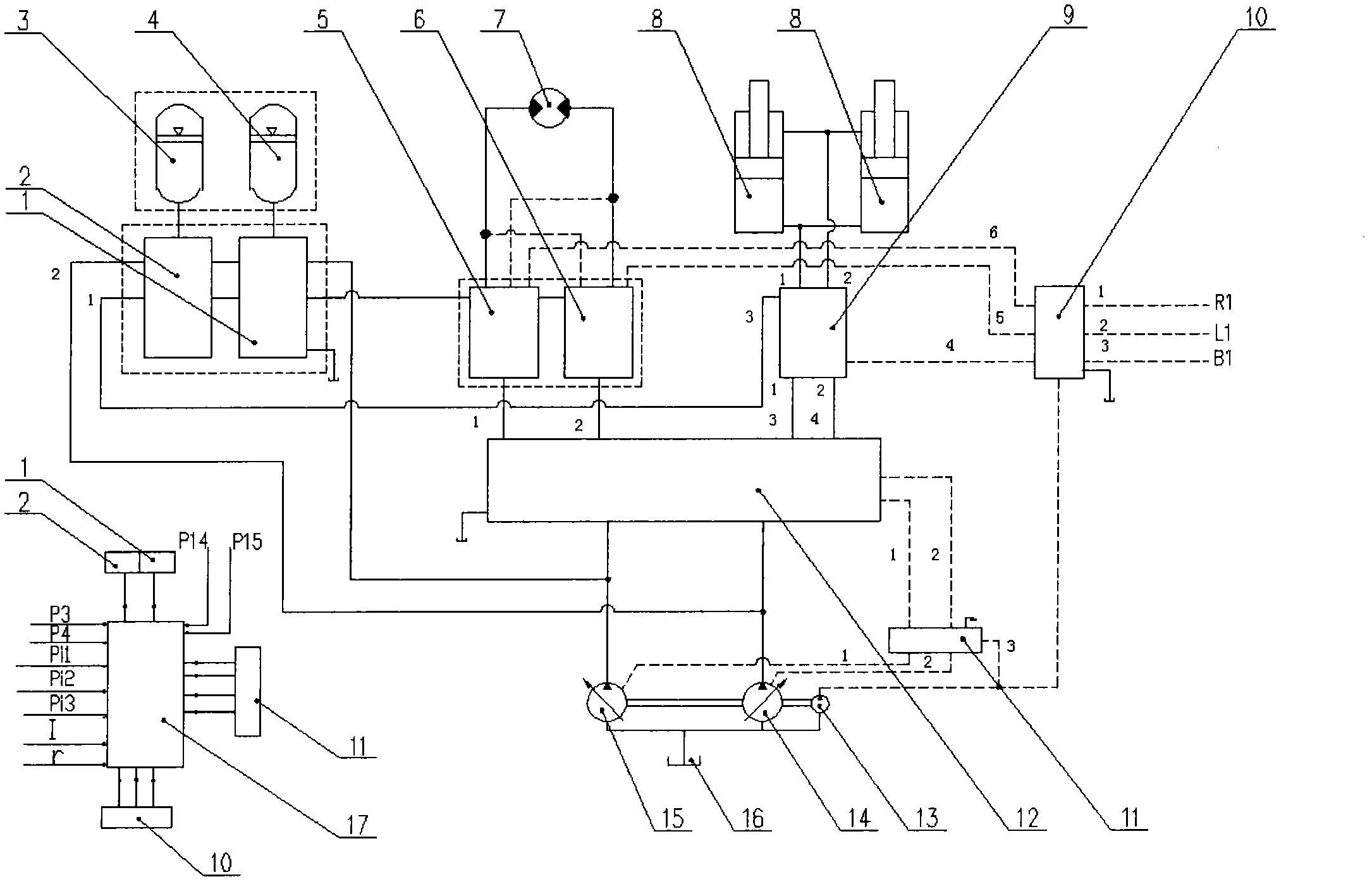

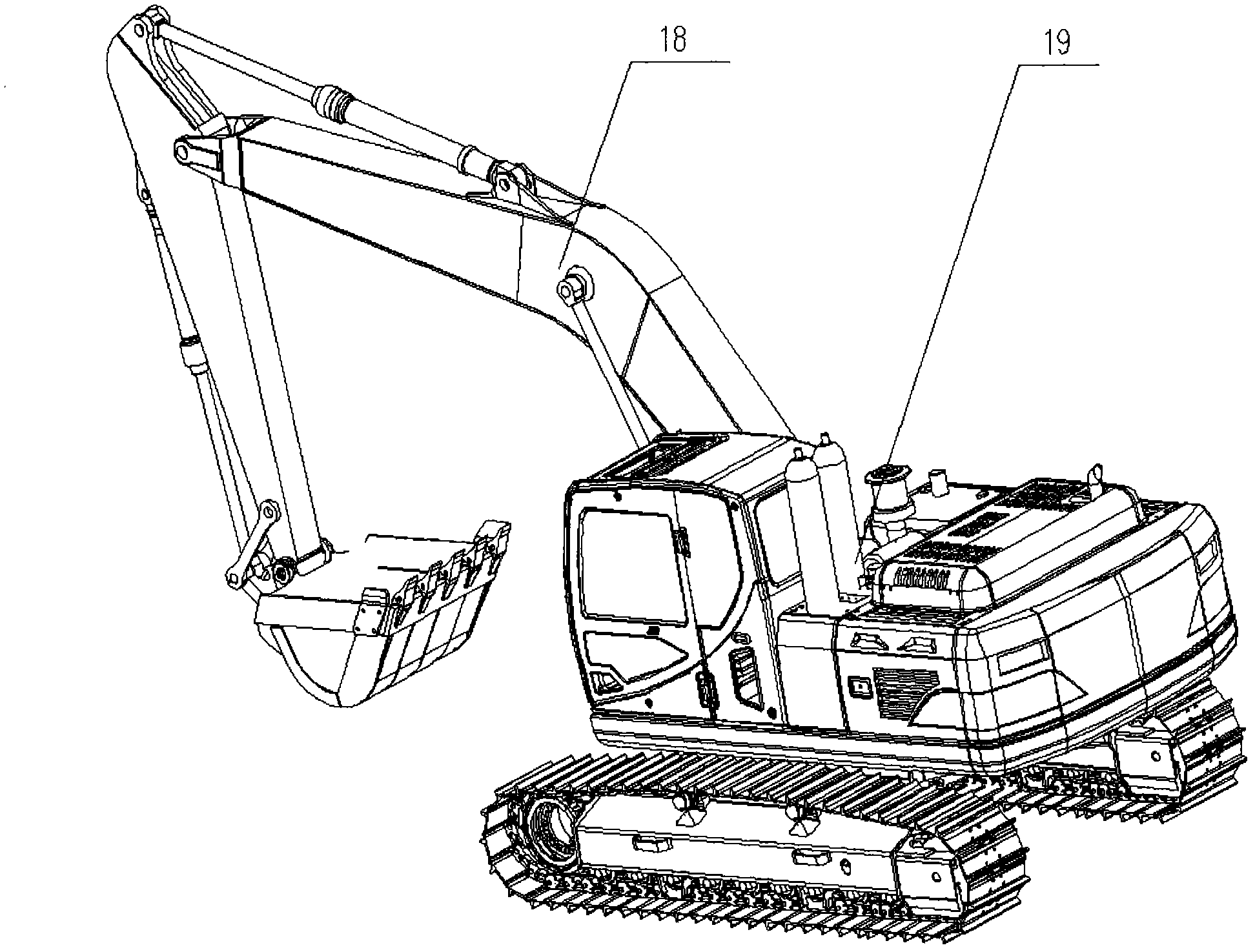

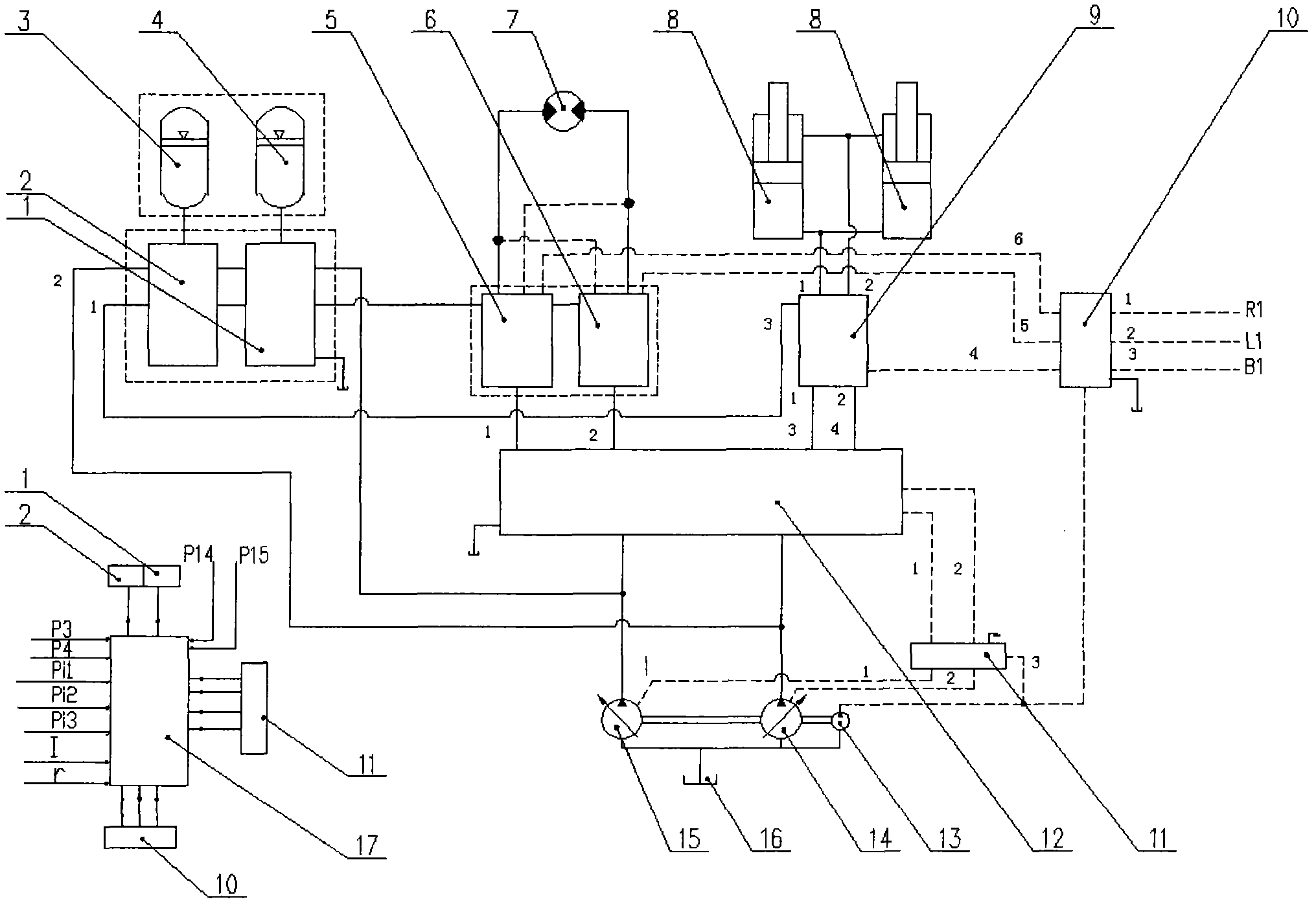

[0025] refer to figure 1 and figure 2 , the control system of the hybrid excavator of the present invention includes a first energy release valve block 1, a second energy release valve block 2, a first accumulator 4, a second energy accumulator 3, and a first rotary energy recovery valve block 5 , the second rotary energy recovery valve block 6, the rotary motor 7, the boom cylinder 8, the boom energy recovery valve block 9, the pilot control valve block 10, the pump control system valve block 11, the multi-way valve 12, the pilot hydraulic pump 13, The first main hydraulic pump 14, the second main hydraulic pump 15, the hydraulic oil tank 16, the hybrid controller 17;

[0026]The outlets of the first main hydraulic pump 14 and the second main hydraulic pump 15 are connected to the oil inlet of the multi-way valve 12 through rubber hoses, and the first pilot oil port of the multi-way valve 12 is connected to the valve block of the pump control system through rubber hoses. 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com