Waste gas treatment apparatus and asphalt mixture heat regeneration equipment

A waste gas treatment device and asphalt mixture technology, which is applied in lighting and heating equipment, combustion methods, combustion types, etc., can solve the problems that the waste gas cannot be treated, and the service life of the filter bag that affects the use effect of the dust collector

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

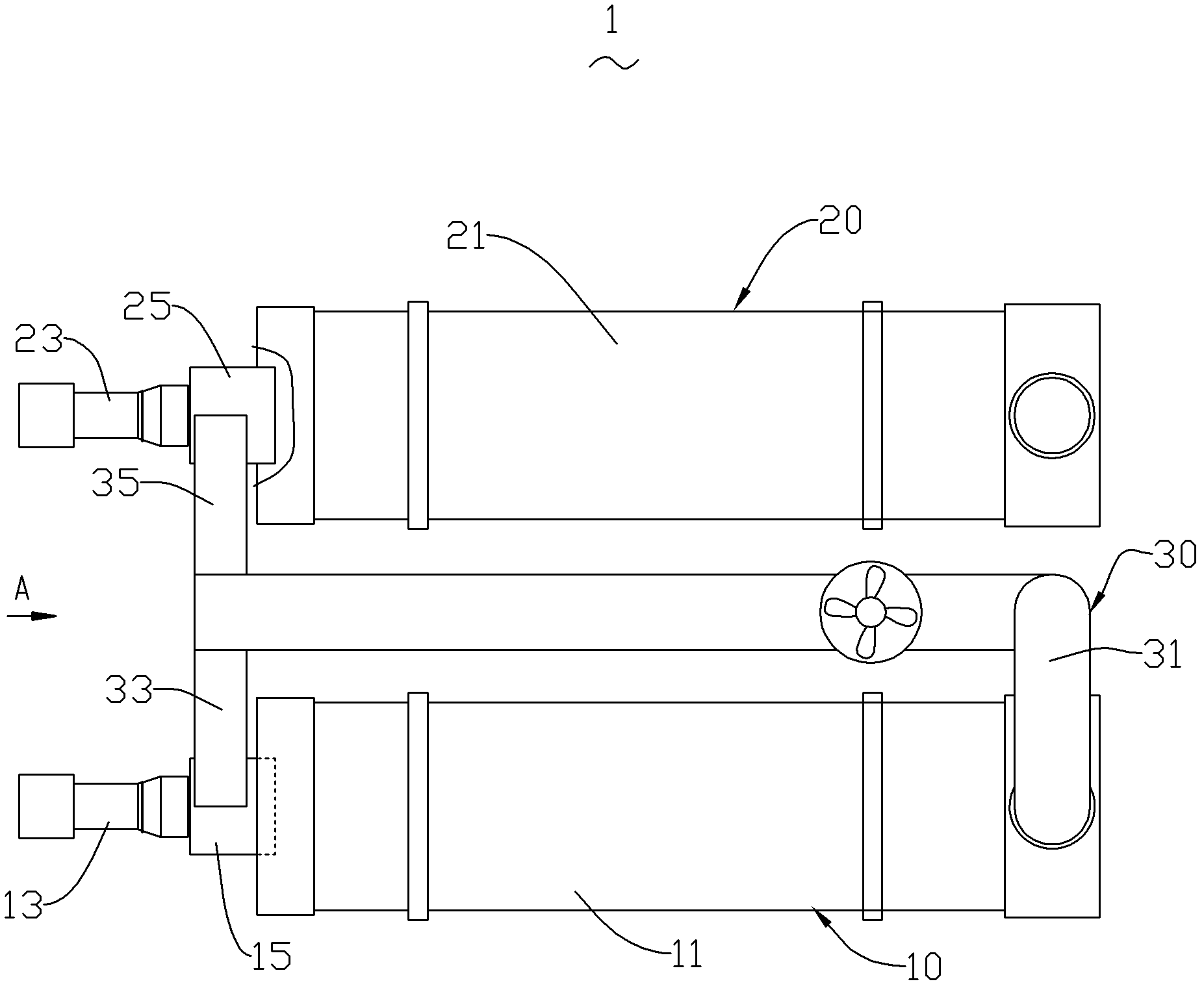

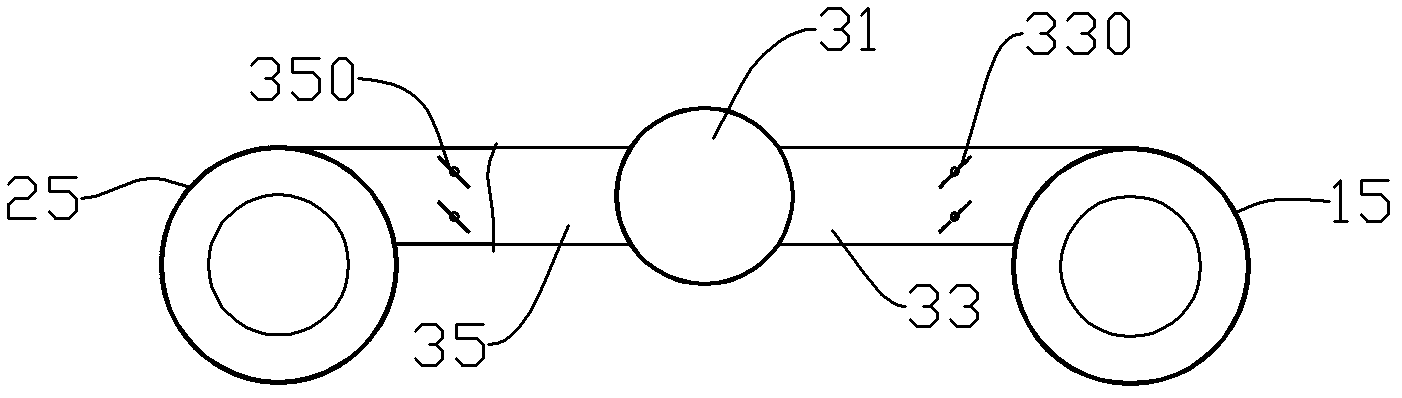

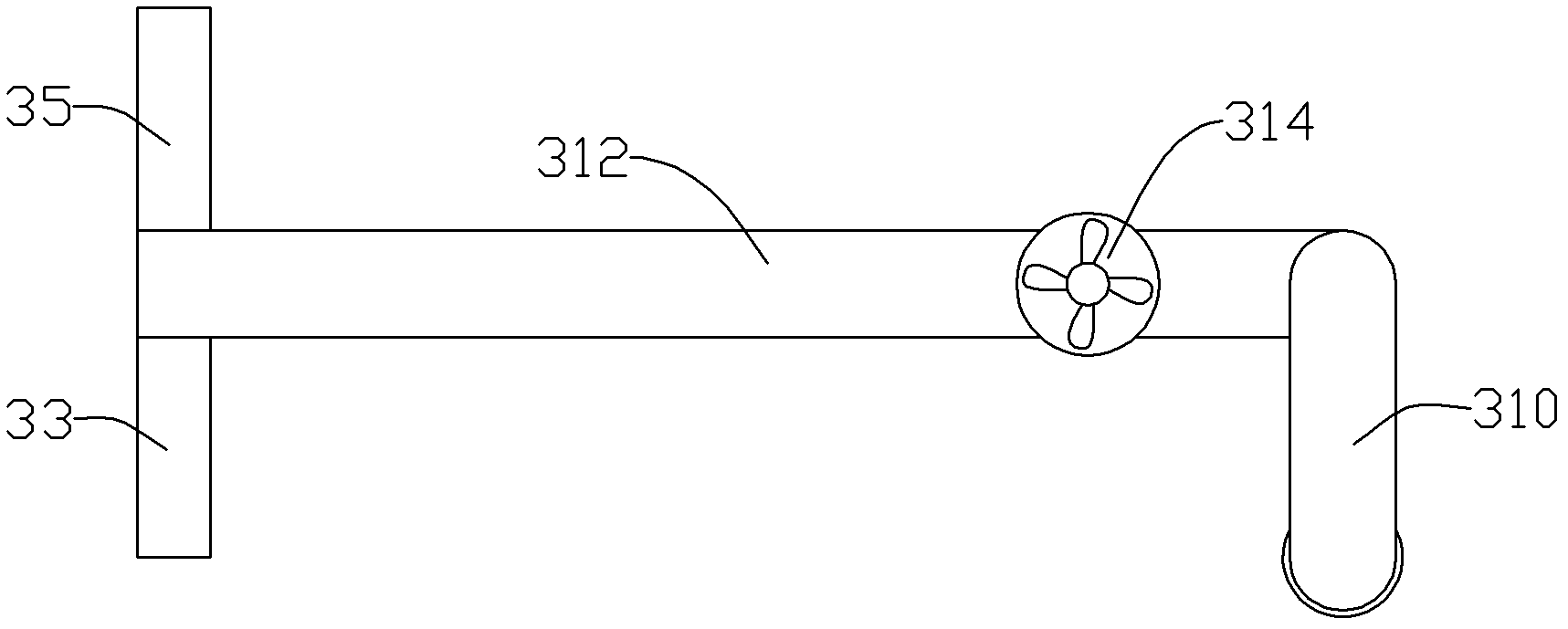

[0021] figure 1 The asphalt mixture thermal recycling plant 1 in some embodiments of the invention is shown, which may include a first drying plant 10 for heating old asphalt material, a second drying plant 20 for heating new aggregate, and a The exhaust gas conveying device 30 that transports the asphalt fume generated during the heating and regeneration of the old asphalt material to a predetermined area for treatment, the first drying equipment 10 and the second drying equipment 20 can be arranged side by side in some embodiments.

[0022] The first drying device 10 may include a first drying drum 11 , a first burner 13 and a first flame cylinder 15 in some embodiments. The first burner 13 is correspondingly arranged at the head of the first drying drum 11, and is used to provide the first drying drum 11 with the high-temperature flue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com