Weaving method and weaving device for multiple-weft high-density water spraying jacquards

A high-density, loom technology, used in textiles and papermaking, textiles, looms, etc., can solve problems such as unfavorable multi-weft water-jet weaving, restricting product development and production, and varying the number of warp yarns to maintain stability. Clear, reduce the build density, and facilitate the effect of normal rebound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

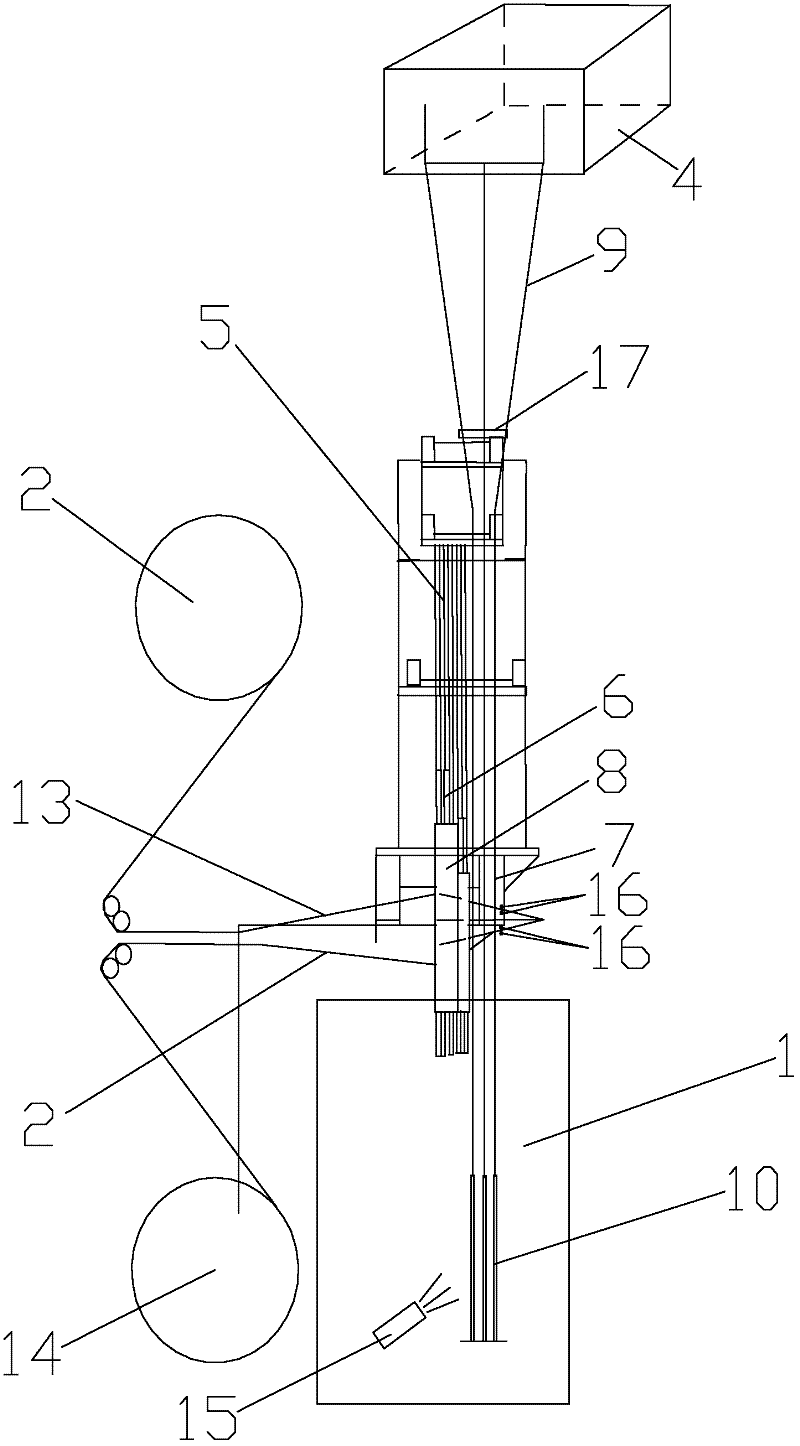

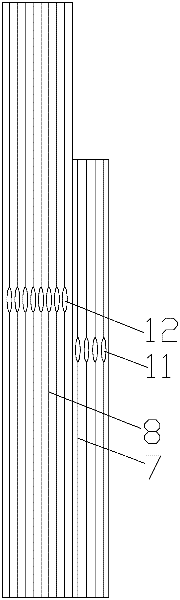

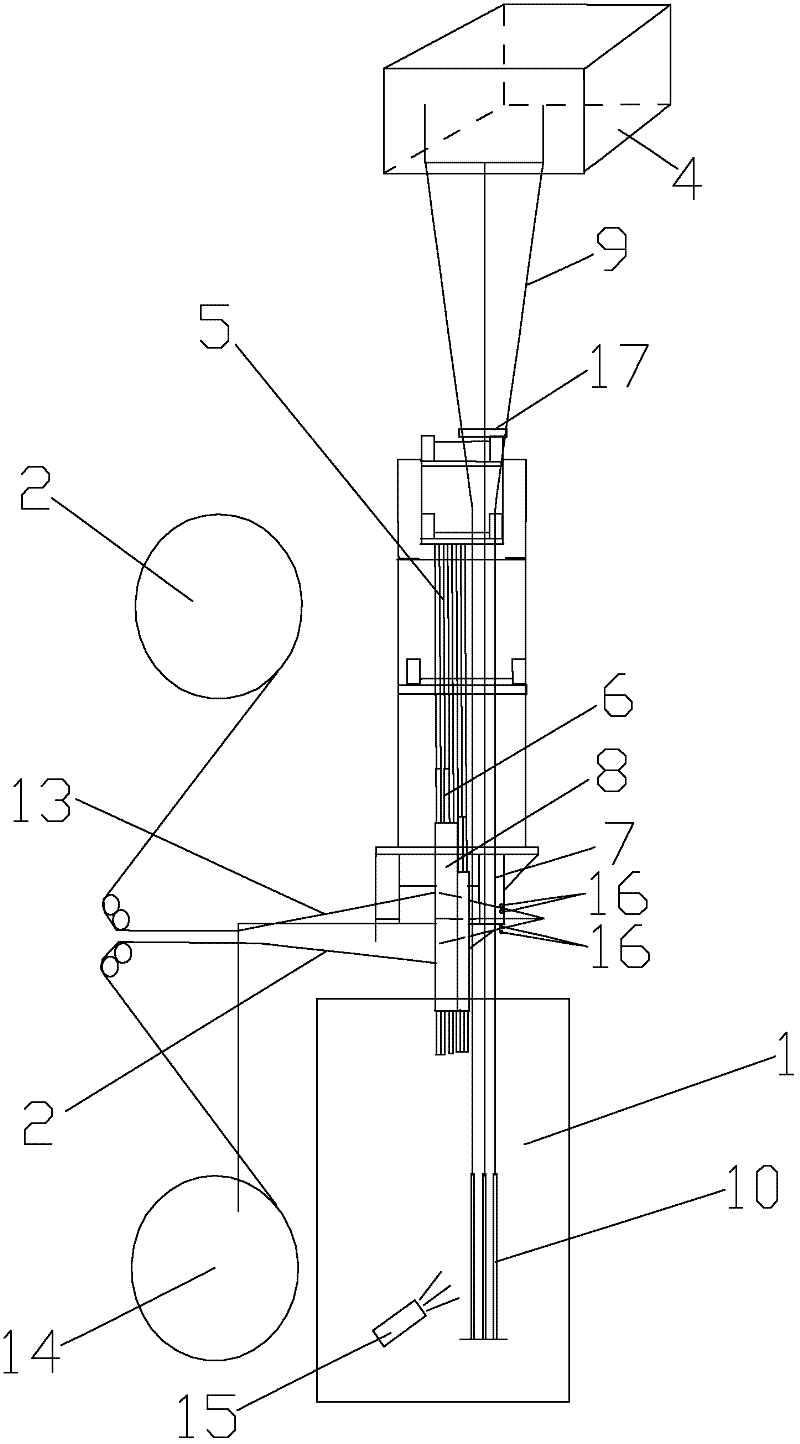

[0018] refer to figure 1 , 2 , a multi-weft high-density water-jet jacquard weaving device, including a loom body 1, a first warp beam 2, a second warp beam 3, a jacquard faucet 4, a dobby faucet 5, a heald frame 6, a number of first heddles 7, a number of second healds Two heddles 8, some harnesses 9, some return heddle springs 10 and at least one weft feeder (because the weft feeder part is similar to the existing common weft feeder, therefore, it is no longer shown in this figure, and it can be referred to during implementation. The structure and position of the ordinary weft feeder), the loom body 1 is equipped with a jacquard faucet 4 and a dobby faucet 5, the jacquard faucet 4 is provided with several harnesses 9, and the lower end of the harness 9 is connected with a first heddle 7 , the lower end of the first heddle 7 is connected with a return heddle spring 10, the lower end of the return heald spring 10 is fixed on the loom body 1, the first heald 7 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com