Production method of 6-nitro-1,2,4-sulfonic acid

A production method and technology of acid oxides, applied in the direction of organic chemistry, etc., can solve the problems of difficult treatment and high production cost of waste gas, and achieve the effects of reducing dosage, improving quality and improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, a kind of production method of 6-nitro-1,2,4-acid oxygen body, its steps are as follows:

[0032] (1) Use ethyl naphthol as raw material, add bottom water, slowly heat up to 50°C until ethyl naphthol dissolves, beat at 50°C and keep warm for 20 minutes, then cool down to 20°C; the bottom water and ethyl naphthol The weight ratio of phenol is 0.8: 1.0; Described bottom water is water;

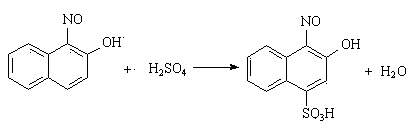

[0033] (2) Nitrosation: Add solid sodium nitrite, beat for 20 minutes, cool down to 0°C, start adding the prepared sulfuric acid solution dropwise, and control the dropping time to 3 hours. Slowly add liquid caustic soda at 10°C to make the system pH to 4; the weight ratio of sodium nitrite, sulfuric acid, ethyl naphthol=0.45:0.34:1.0, the concentration of sulfuric acid solution is 5%;

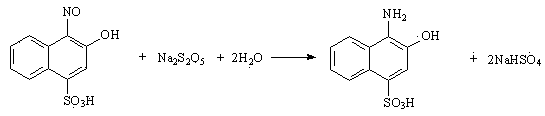

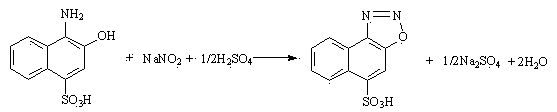

[0034] (3) Sulfonation and reductive translocation: add sodium metabisulfite, keep warm for 20 minutes, then raise the temperature to 15°C, keep warm for 0.5 hours, stop stirring, stand sti...

Embodiment 2

[0037] Embodiment 2, a kind of production method of 6-nitro-1,2,4-acid oxygen body, its steps are as follows:

[0038] (1) Use ethyl naphthol as raw material, add bottom water, slowly heat up to 80°C until ethyl naphthol dissolves, beat at 80°C and keep warm for 40 minutes, then cool down to 40°C; the bottom water and ethyl naphthol The weight ratio of phenol is 1.5:1.0; the bottom water is water, the reaction mother liquor (the filtrate produced by filtering in step (3), or the mother liquor and filtrate produced by the washing in step (4)) or a mixture of the two;

[0039] (2) Nitrosation: Add solid sodium nitrite, beat for 40 minutes, cool down to 10°C, start adding the prepared sulfuric acid solution dropwise, and control the dropping time to 8 hours. Slowly add liquid caustic soda at 20°C to make the system pH to 7; the weight ratio of sodium nitrite, sulfuric acid and ethyl naphthol=0.55:0.68:1.0, the concentration of sulfuric acid solution is 30%;

[0040](3) Sulfonati...

Embodiment 3

[0043] Embodiment 3, a kind of production method of 6-nitro-1,2,4-acid oxygen body, its steps are as follows: add 800 parts of bottom water (both parts by weight, the same below) in the reactor, drop in ethyl naphthalene 1000 parts of phenol, slowly heat up to 50°C, observe whether ethyl naphthol is dissolved, beat at 50°C and keep warm for half an hour, then cool down to 20°C, add 450 parts of solid sodium nitrite, beat for half an hour, cool to 0°C, Start to drop 340 parts (100 percent) of the configured sulfuric acid solution, the solubility of the sulfuric acid solution is 30%, the dropping time is controlled to 3 hours, the dropping is completed, and the heat preservation reaction is 1 hour. Then raise the temperature to 10°C and slowly add liquid caustic soda to make the system pH to 4. Then add 1500 parts of sodium metabisulfite, keep the reaction for 0.5 hours, then raise the temperature to 15° C., keep the reaction for 1 hour, stop stirring, stand still, and filter. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com