Ceramic brick produced by using rare earth tailings and production method thereof

A rare earth tailings and manufacturing method technology, applied in the field of ceramic tiles, can solve problems such as failure to meet the national standards for porcelain tiles, decrease in green body strength, and restrictions on the amount of rare earth tailings, so as to expand the sintering temperature range and reduce the sintering temperature. Temperature, the effect of expanding the range of sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

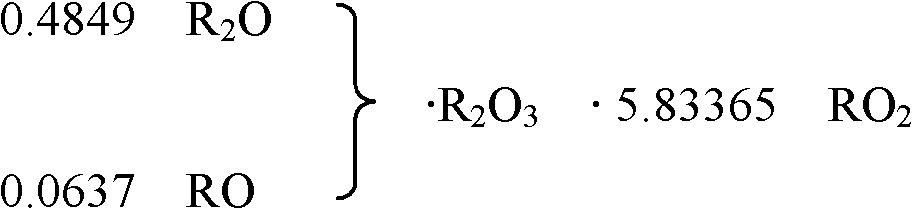

[0029] 1. In this embodiment, the ceramic brick prepared with rare earth tailings, the green body is composed of:

[0030] Rare earth tailings 65%, Guangdong black mud 10%, albite 15%, lithium china stone 10%.

[0031] Add composite additives in addition, and its consumption is 0.4% of green body by weight percentage. The composite additive is a combination of hydroxymethyl propyl cellulose and amphoteric starch, and the ratio by weight of hydroxymethyl propyl cellulose: amphoteric starch is 2:2.

[0032] 2, the preparation method of present embodiment ceramic tile is as follows:

[0033] (1) Put the above materials into the ball mill, according to raw materials: ball: water = 1: 1.5: 0.8, mix and ball mill for 11 hours to obtain slurry;

[0034] (2) The slurry is sequentially deironed, sieved, spray granulated, and pressed to obtain a green body;

[0035] (3) After the green body is dried at 110°C for 60 minutes, it enters the firing equipment. The firing temperature is 10...

Embodiment 2

[0042] 1. In this embodiment, the ceramic brick prepared with rare earth tailings, the green body is composed of:

[0043] Rare earth tailings 70%, Guangdong black mud 12%, albite 5%, lithium china stone 10%, wollastonite 3%.

[0044] In addition, composite additives are added, and its consumption is 0.6% of the green body by weight percentage. The composite additive is a combination of hydroxymethyl propyl cellulose and amphoteric starch, and the ratio by weight of hydroxymethyl propyl cellulose: amphoteric starch is 3:1.

[0045] 2, the preparation method of present embodiment ceramic tile is as follows:

[0046] (1) Put the above materials into the ball mill, according to raw materials: ball: water = 1: 1.6: 0.7, mix and ball mill for 12 hours to obtain slurry;

[0047] (2) The slurry is sequentially deironed, sieved, spray granulated, and pressed to obtain a green body;

[0048] (3) After the green body is dried at 100°C for 65 minutes, it enters the firing equipment. T...

Embodiment 3

[0055] 1. In this embodiment, the ceramic brick prepared with rare earth tailings, the green body is composed of:

[0056] Rare earth tailings 80%, Guangdong black mud 8%, lithium china stone 8%, lepidolite 2%, boronite 2%.

[0057] In addition, composite additives are added, and its consumption is 0.7% of the green body by weight percentage. The composite additive is a combination of hydroxymethyl propyl cellulose and amphoteric starch, and the ratio by weight of hydroxymethyl propyl cellulose: amphoteric starch is 4:1.

[0058] 2, the preparation method of present embodiment ceramic tile is as follows:

[0059] (1) Put the above-mentioned materials in the ball mill, according to raw material: ball: water=1: 1.4: 0.8, mix ball mill for 10h to obtain slurry;

[0060] (2) The slurry is sequentially deironed, sieved, spray granulated, and pressed to obtain a green body;

[0061] (3) After the green body is dried at 120°C for 75 minutes, it enters the firing equipment. The fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com