System for automatically putting away and laying down metal substrates

A metal substrate, automatic retractable technology, applied to conveyor objects, transportation and packaging, etc., can solve the problems of high physical labor intensity, can not guarantee that the product will not be scratched, bumped, low efficiency, etc., to reduce labor intensity , not easy to damage, improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

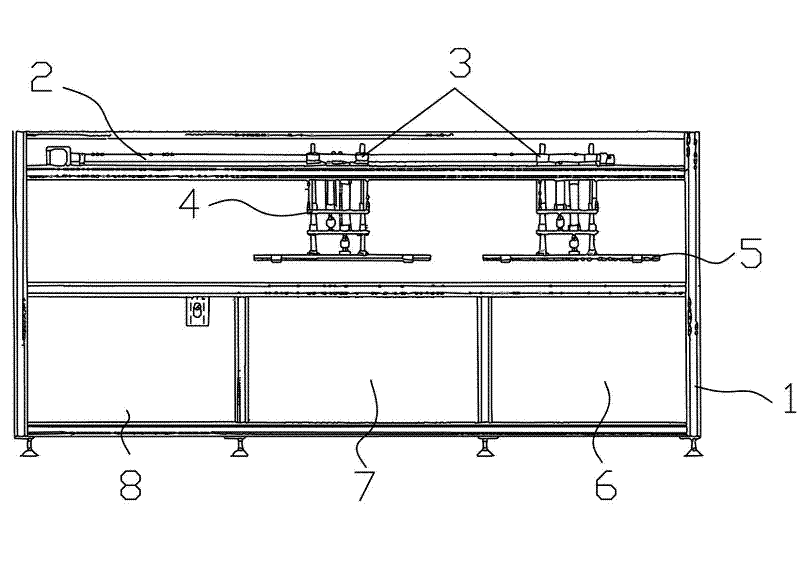

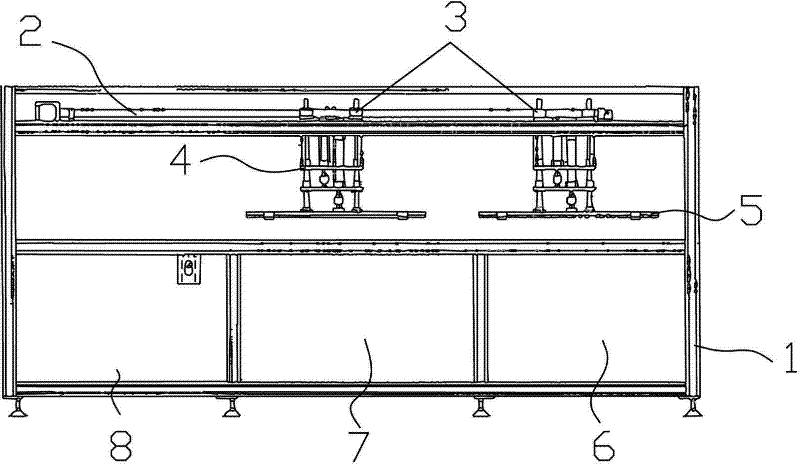

[0014] refer to figure 1 and figure 2 , a metal substrate automatic retractable plate system of the present invention, comprising a frame 1, a linear guide rail 2 is arranged above the frame 1, and two slide rails that can move synchronously on the linear guide rail 2 are arranged on the linear guide rail 2. The lower part of the seat 3 and the sliding seat 3 is connected with the suction plate device 5 through the lifting device 4, and the position directly below the linear guide rail 2 at the lower part of the frame 1 is sequentially provided with equally spaced distribution for storing the films used to space the metal substrates. Spacer room 6, sheet material room 7 for storing metal substrates with film intervals, and conveying room 8 for conveying metal substrates. Conveyor belts 9 that can move in both directions are arranged in the conveying room 8, and two linear guide rails 2 The distance between each sliding seat 3 is equal to the spacing distance between 6 and 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com