Plate frame hydraulic press for mold pressing of large blocks and plates

A plate-and-frame hydraulic press technology, applied in the field of hydraulic presses, can solve problems such as high manufacturing and use costs, complex press manufacturing process, and deviation of mechanical properties of castings, and achieve the effects of reduced weight, high rigidity, and high fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

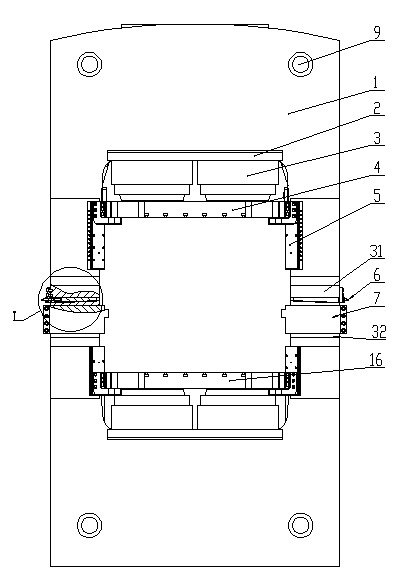

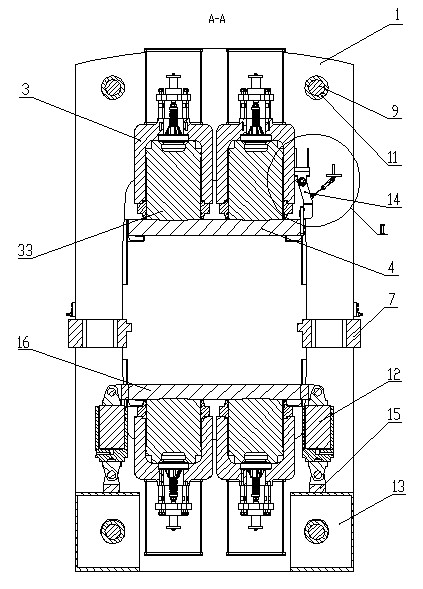

[0019] From figure 1 — Figure 9 It can be seen that a plate and frame hydraulic press for pressing large molded blocks and molded plates is characterized in that the plate and frame hydraulic press for pressing large molded blocks and molded plates is mainly composed of a frame, an upper pressing device, an upper movable The beam device, the lower pressing device, the lower movable beam device, the mold frame fixing device, the safety device and the auxiliary oil cylinder device are composed of the front and rear main boards 1, the oil cylinder fixing plate 2, the main connecting screw 9, the spacer 11 and the Composed of nuts 10, the front and rear main boards 1 are symmetrically spaced to be vertically arranged, and rectangular holes are symmetrically provided in the middle of the front and rear main boards 1 respectively. The convex arc transition is better, and the outer surfaces of the left and right sides of the front and rear main boards 1 respectively correspond t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com