Method for repairing single roller of sintering machine

A repair method, technology of sintering machine, applied in welding medium, welding/cutting medium/material, manufacturing tools, etc., can solve the performance degradation of single roller high temperature resistance, wear resistance, equipment and personal safety accidents, tooth crown welding It can reduce the consumption of spare parts, improve the service life, and ensure safe and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

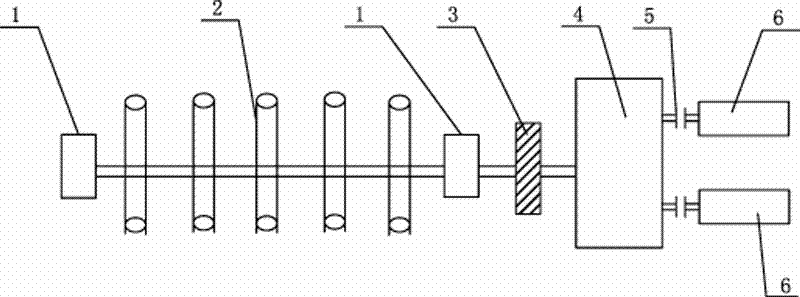

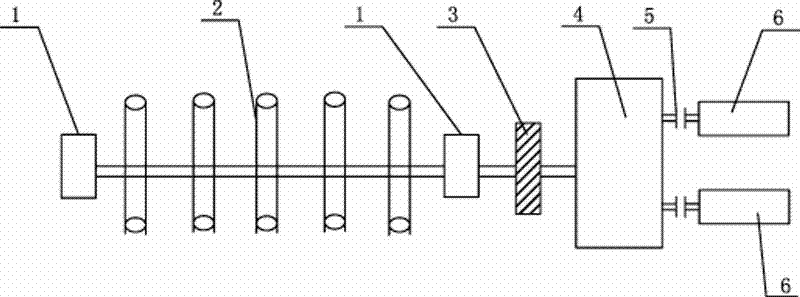

[0011] Such as figure 1 As shown, the single roll of the sintering machine of the present invention mainly includes a motor 6, a reducer 4, a single roll body 2, a tooth crown, a bearing seat 1, a safety friction coupling 3, a coupling 5 and a cooling waterway. The single-roller body 2 is connected to the tooth crown by surfacing welding, and is fixed by the bearing seat 1. The tooth crown part in contact with the material adopts a convex structure. Through the high-speed rotation of the single-roller body 2, the tooth crown contacts with the high-temperature material, thereby achieving crushing. The purpose of the material. The bearing seat 1 is connected with the reducer 4 through the safety friction coupling 3 , and the reducer 4 is connected with the motor 6 through the coupling 4 . The present invention connects the surfacing-welded tooth crowns with the single-roller body 2, and adopts GR-AJ557 high-strength connecting electrode for surfacing welding connection, which a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com