Method for stably controlling stirring states in stirring barrel

A technology of stable control and mixing barrels, applied in mixers with rotating mixing devices, mixing methods, mixer accessories, etc., can solve problems such as not being raised, and achieve the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

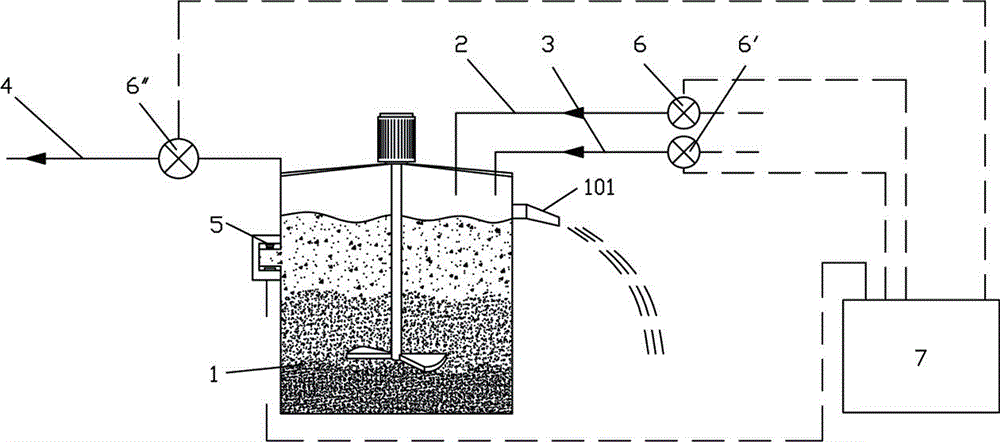

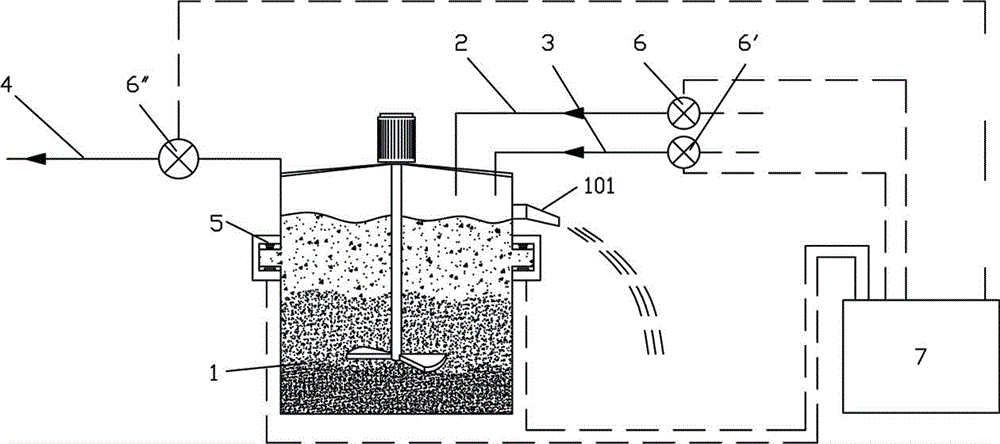

[0051] The method for stably controlling the stirring state in the mixing tank of the present invention comprises the following steps:

[0052] 1) Determine the parameters of the initial state of the mixing tank:

[0053] (1) The equivalent coefficient K=6 in the mixing tank, that is, the difference between the average concentration value of all media in the tank and the concentration measurement value at a measuring point 10cm away from the liquid surface of the mixing tank (where the actual measured value is not higher than 15%) The ratio between;

[0054] (2) After the mixing tank 1 is injected with the medium, the time required to reach a stable stirring state is 5 s;

[0055] (3) The mixing tank needs to control the target average concentration value Z 0 =48%, that is, the concentration of the measuring point is N 0 = 8%;

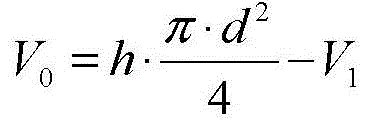

[0056] (4) The volume of the mixing tank is: V 0 = h · ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com