Full-automatic internal circulating gas drying device

A technology of gas drying and internal circulation, which is applied to the separation of dispersed particles, chemical instruments and methods, and separation methods. It can solve the problems of large regeneration gas consumption, short switching time, and product gas consumption, and achieve high drying efficiency and reasonable structure. , good working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

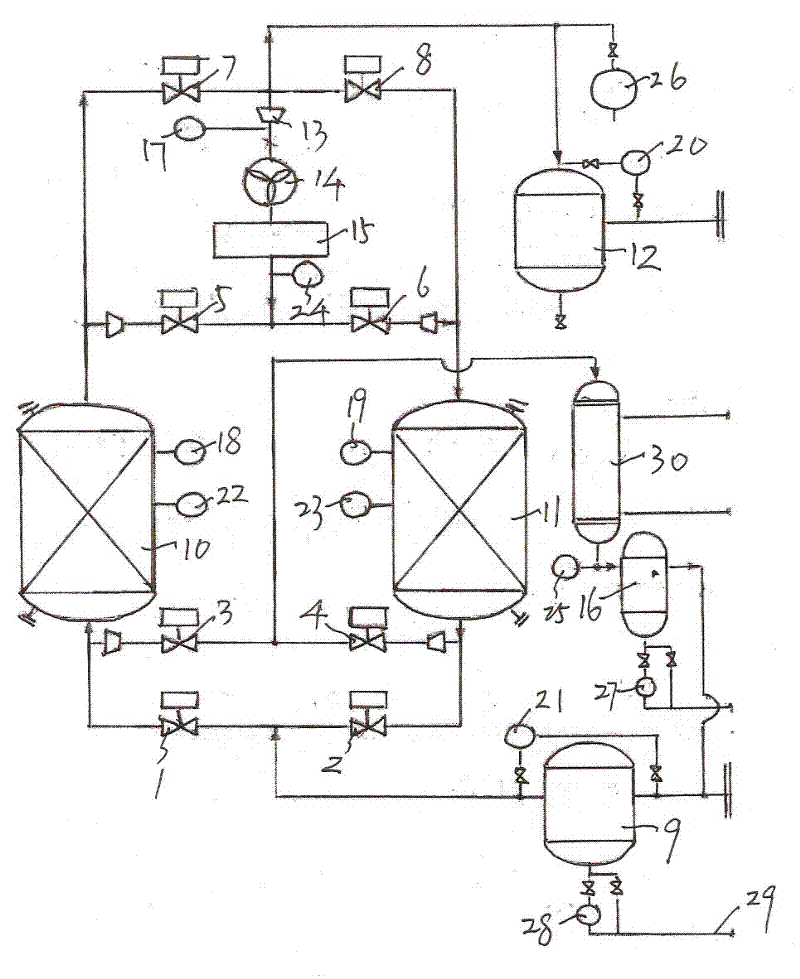

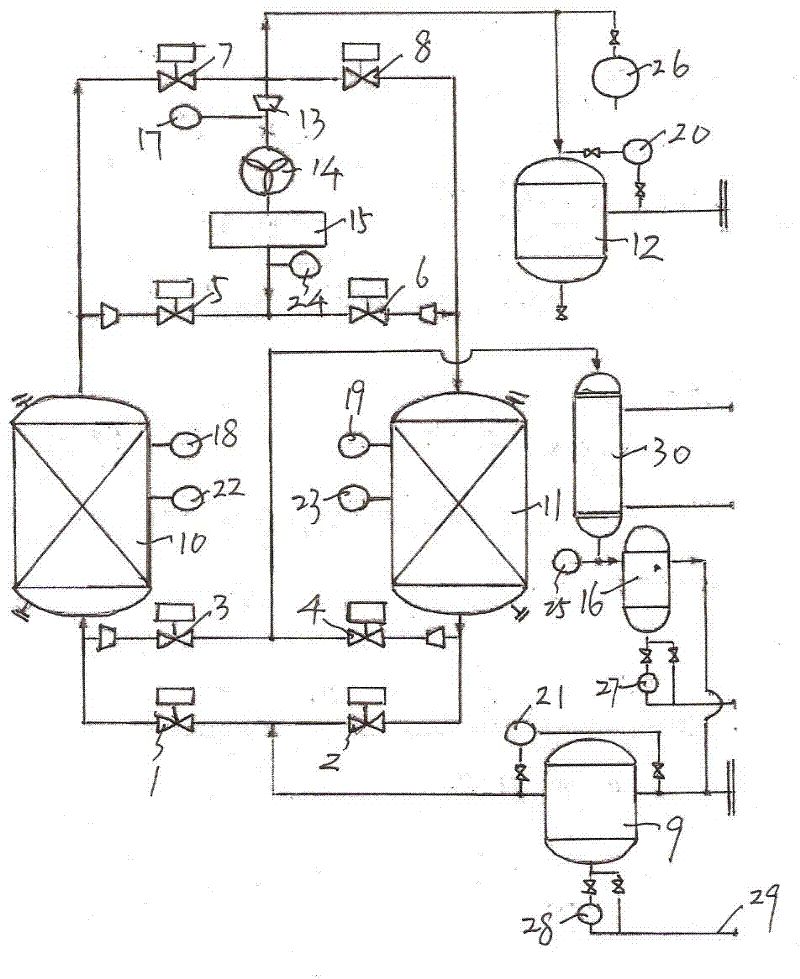

[0014] A fully automatic internal circulation gas drying device, comprising a front oil removal filter 9, the front oil removal filter respectively passes through the first and second valves 1, 2 and the first and second drying towers 10, 10, and 10 equipped with moisture adsorbents 11 connection, the first and second towers are respectively connected to the post-dust filter 12 through the seventh and eighth valves 7 and 8, the post-dust filter 12 is connected to the product gas output system, and the first and second drying towers are also respectively passed through The seventh and eighth valves 7 and 8 are connected to the regeneration gas regulating valve 13, the regeneration gas regulating valve is connected to the pressurized fan 14, the fan is connected to the electric heater 15, and the electric heater passes through the fifth and sixth valve 5 respectively. , 6 are connected with the first and second drying towers 10 and 11, and the first and second drying towers are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com