Steam oven

A technology for a steam oven and an oven body, which is applied in the field of steam ovens, can solve the problems of high sealing requirements of sealed pipes, large number of assembly processes and parts, high requirements for heating devices, etc., and achieves simple and reasonable structure, flexible design, and high structure. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

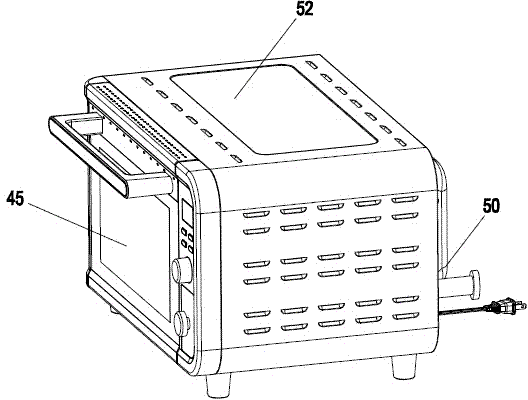

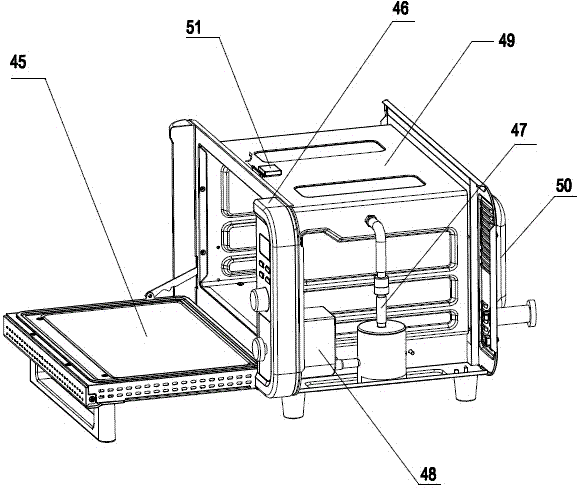

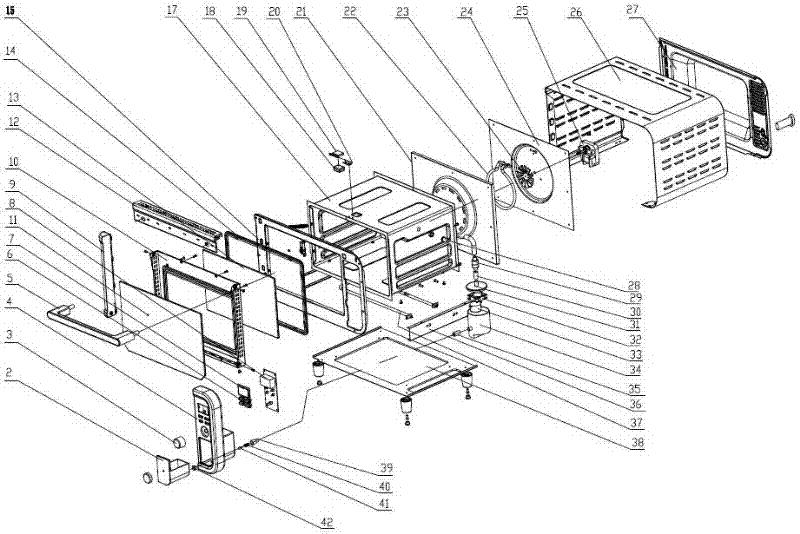

[0023] The structure diagram of the present invention is as figure 1 , 2 , 3, and 4, the steam oven of the present invention includes a door body assembly 45, a control panel assembly 46, an atomizer assembly 47, a water tank assembly 48, an oven body assembly 49 provided with a cooking cavity, and a rear hot air convection The heating assembly 50, the pressure relief valve assembly 51, the oven body assembly 49 and the housing 52, wherein the oven body assembly 49 is installed in the hollow cavity of the housing 52, and the water tank assembly 48 is installed in the installation cavity provided by the oven body assembly 49 On the other side, the atomizer assembly 47 is installed on the side of the water tank assembly 48, the rear hot air convection heating assembly 50 is installed on the rear side of the oven body assembly 49, and the door assembly 45 is installed on the side of the oven body assembly 49. On the front side, the control panel assembly 46 is installed on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com