CNC (Computer Numerical Control) board splitting production method without NPTH (Non Plating Through Hole) hole positioning

A hole positioning, gong plate technology, used in milling machine equipment, electrical components, printed circuit manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A CNC gong plate production method without NPTH hole positioning of the present invention, in order to make the purpose, technical solution and advantages of the present invention clearer and clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0029] Among them, the gong board is to use the gong machine to output the specified jigsaw pattern on the circuit board through the milling cutter according to the pre-programmed program. Advantages: According to the program, various shapes of jigsaw patterns can be produced on the board, several boards can be overlapped and processed at the same time, the molding size of the board is high, and the interface of the board is smooth.

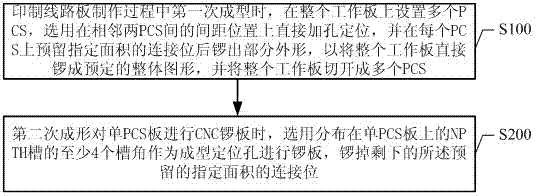

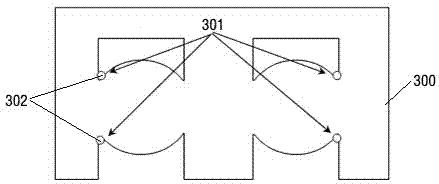

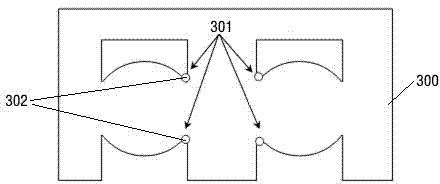

[0030] Such as figure 1 As shown, a CNC gong board production meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com