Internal cable tension measuring device for tension attenuation winch

A measuring device and built-in technology, applied in the direction of tension measurement, etc., can solve problems such as the blockage of the bearing block and affect the accuracy of tension measurement, and achieve the effect of ensuring accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

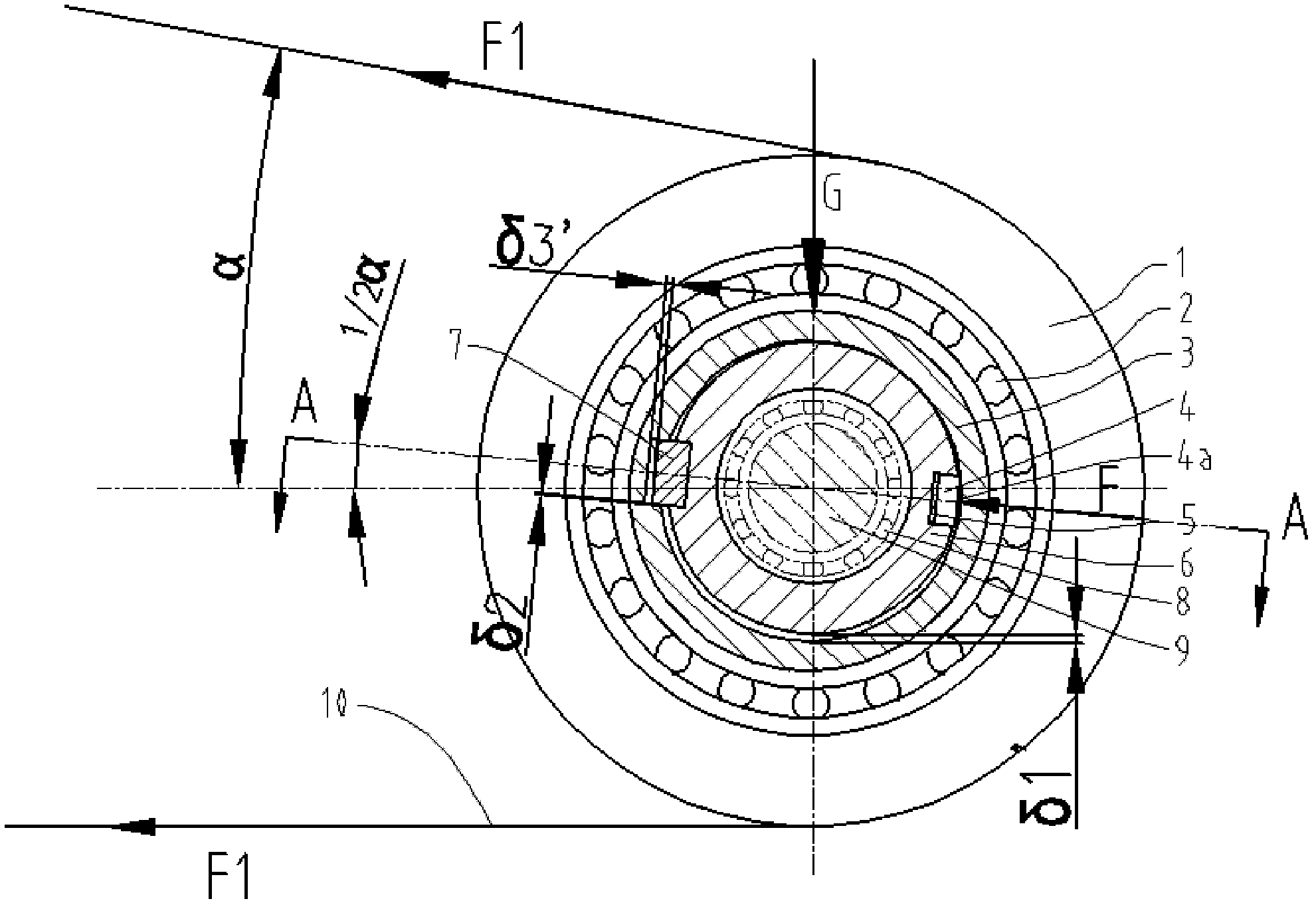

[0018] figure 1 It is a schematic diagram of the structure of the device in the unstressed state of the cable, which includes tension wheel 1, large bearing 2, force application sleeve 3, force sensor 4, sensor seat 5, flat key 7, flange sleeve 6 from outside to inside; tension wheel 1 Inner hole and large bearing 2 Outer ring set, large bearing 2 Inner ring and force sleeve 3 Outer circle set, force sleeve 3 and flange sleeve 6 Set, flange sleeve 6 is fixed to the winch box, flange sleeve 6 Cooperate installation through bearing 8 and supporting shaft 9 in the hole.

[0019] When the cable 10 is not stressed, under the action of the gravity G of the tension wheel 1, the large bearing 2, and the force application sleeve 3, the gap δ1 between the inner hole of the force application sleeve 3 and the outer circle of the flange sleeve 6 is located below. At this time There is also a gap δ4 between the contact 4a of the sensor 4 and the inner hole of the force application sleeve, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com