Sheet-metal reinforced composite electric pole and production method for same

A technology for reinforcing composite materials and metal sheets, applied in chemical instruments and methods, lamination auxiliary operations, lamination devices, etc., can solve the problems of low bending strength, heavy weight, inconvenient transportation and handling of plastic poles, etc., to achieve Overcoming the effects of low bending strength, heavy weight and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

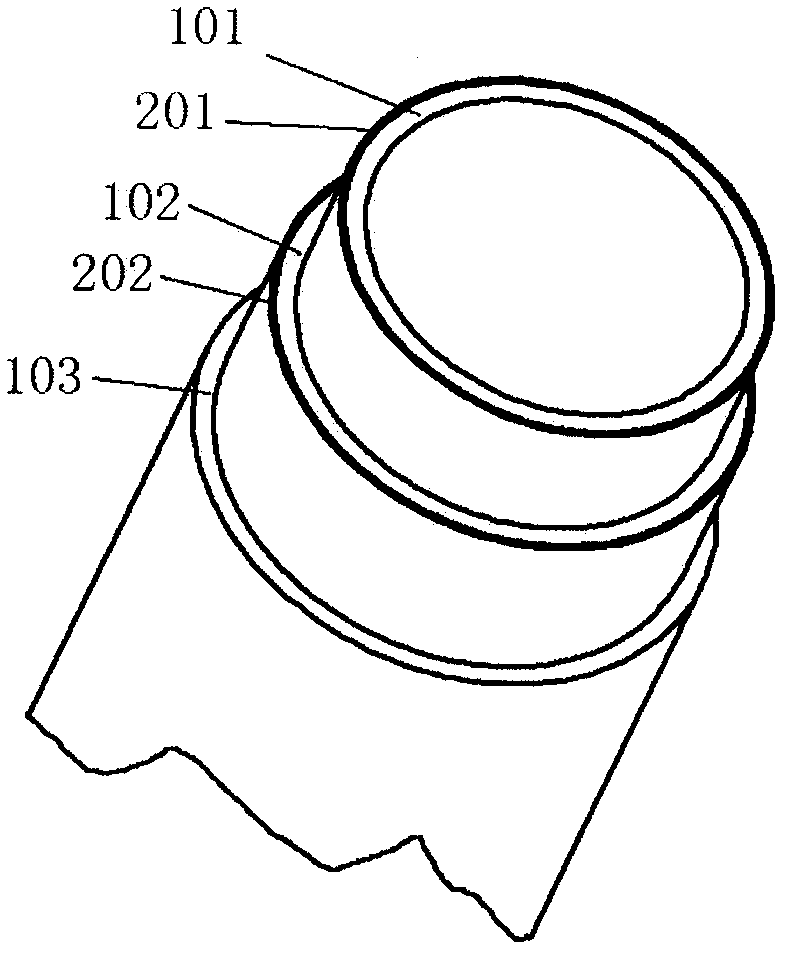

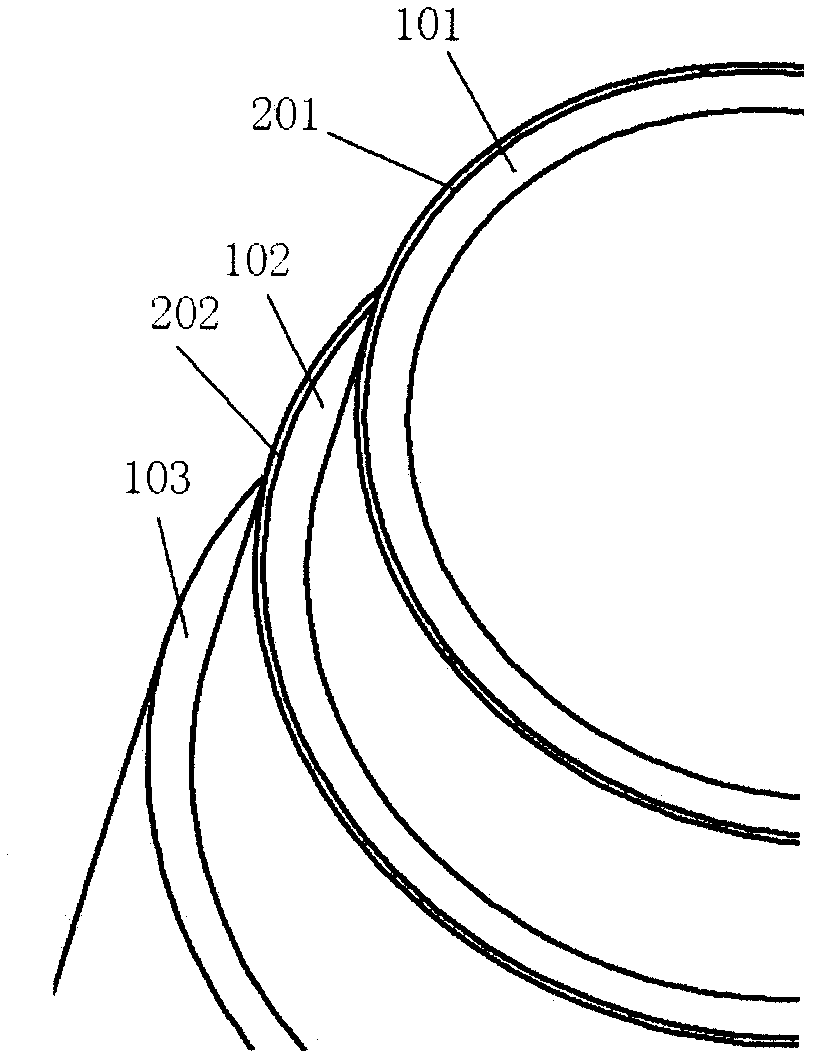

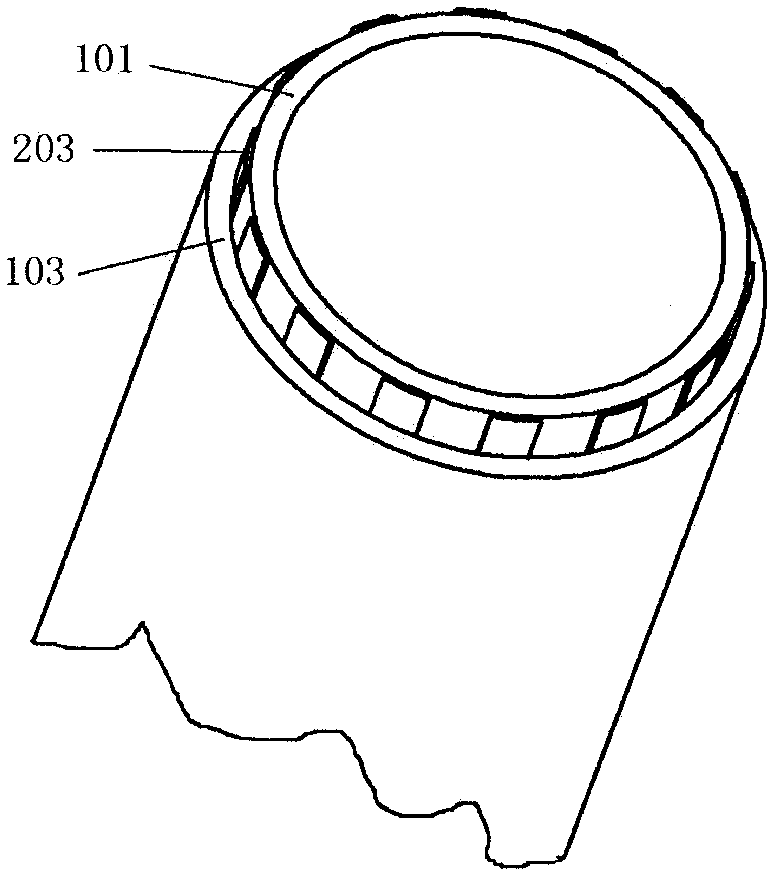

[0029] attached figure 1 It is a three-dimensional schematic diagram of the metal thin plate reinforced composite material electric pole metal thin plate of the present invention being tubular and two-layer, with the attached figure 2 is attached figure 1 The partially enlarged schematic diagram of the end of the metal thin plate reinforced composite material electric pole of the present invention, in the figure, 101 is the inner layer of the composite material pole, 102 is the middle layer of the composite material pole body, 103 is the outer layer of the composite material pole, and 201 is the first reinforcement layer, 202 is the second reinforcement layer. It can be seen from the figure that the metal thin plate reinforced composite material pole of the present invention includes a metal thin plate and a composite material pole body, wherein the metal thin plate is arranged in the middle of the composite material pole body, and the composite material pole body is wound by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com