Method for centering of shafting of reamer of dredger

A dredger and shafting technology, which is applied in the field of dredger reamer shaft alignment, can solve the problems of work difficulty, large labor load, low installation accuracy, long installation period, etc., and achieves good working conditions and no abnormality. Effects of vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

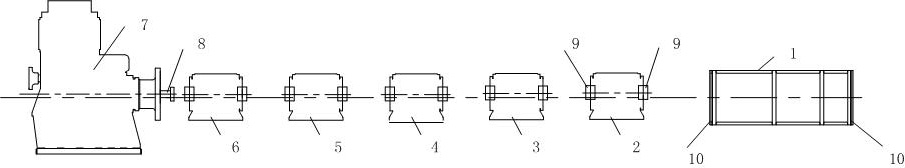

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0031] The present invention aims at the problems of low installation accuracy, high labor load and high work difficulty of the existing dredger cutter shaft alignment method, and provides a dredger cutter shaft alignment method, which can solve the problems existing in the prior art. The installation accuracy is low, the work is difficult and the labor load is large, and the installation cycle is long.

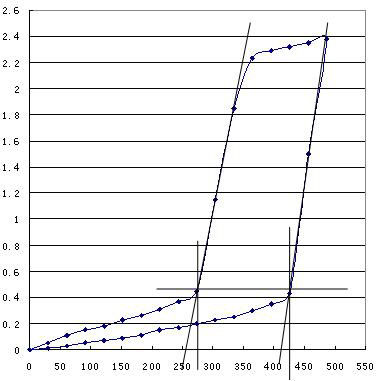

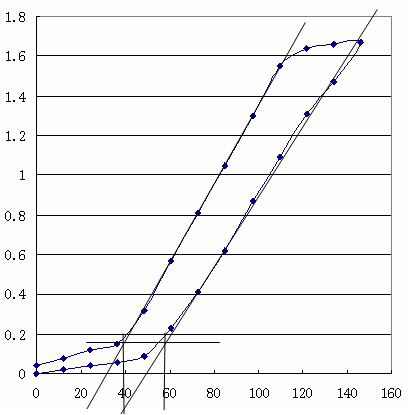

[0032] The determination of the theoretical center line of the ship's shafting system and the alignment and installation of the shafting system are key processes in the shipbuilding process. The quality of alignment and installation will directly affect the reliability and durability of the ship's main engine, shafting and other equipment. sex. The present invention promptly passes to 4000m 3 / h Discussion on reasonable alignment m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com