Self-compacting mortar combination and preparation method thereof

A self-compacting and mortar technology, applied in the field of building materials, can solve the problems of lack of suitable self-compacting mortar, etc., and achieve obvious energy saving and emission reduction benefits, small segregation, and good perfusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Self-compacting mortar preparation: prepared according to different self-compacting mortar ratio requirements, the self-compacting mortar production process includes: (1) Preparations before production: ① Select the self-compacting mortar ratio and prepare the corresponding raw materials; ② Before the production of self-compacting mortar, the raw materials should be tested to understand the moisture content and fineness modulus of the sand. ③ Make sure that the water in the transport tanker has been drained, and pay attention to stirring during transportation. (2) Matters needing attention in the production process: ① The mixing sequence of the self-compacting mortar is: put the weighed sand and cementitious materials into the mixer for dry mixing, and the dry mixing time of the mixer should not be less than 10 seconds. After adding water and admixtures Then continue to stir for more than 60 seconds. When the temperature is lower than 15°C, the stirring time should not ...

Embodiment 2 to Embodiment 6

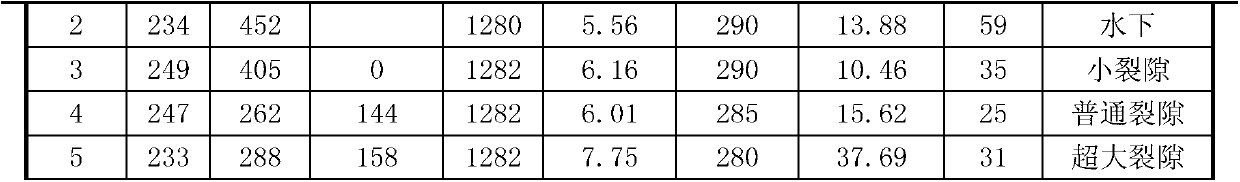

[0040] Prepare the self-compacting mortar according to the ratio in Table 1 and test it, and compare it with the test results of cement slurry and ordinary mortar. The test results are shown in Table 2.

[0041] Table 1 Weight ratio of self-compacting mortar suitable for different cracks

[0042]

[0043]

[0044] In Table 1, SF(cm) is the diffusivity, VF(s) is the time through the standard V-shaped funnel, P 28 Mpa is the 28-day compressive strength.

[0045] Table 2 Comparison of performance indicators of cement slurry, ordinary mortar and self-compacting mortar

[0046] serial number

Performance parameters

Ordinary Mortar

self compacting mortar

1

Initial setting time (min)

121

210

240

2

Final setting time (min)

180

270

460

3

3-day compressive strength (MPa)

25.1

1.96

2.1

4

7-day compressive strength (MPa)

28.3

5.69

5.6

5

28-day compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com