Powder grinding aid capable of improving cement performance

A grinding aid and performance technology, applied in the field of cement grinding, can solve the problems of failure to exert the best effect of cement grinding aids, inability to combine effective grinding aid ingredients, and inability of cement production enterprises to save costs, etc., to achieve cost performance High, save power consumption, improve the effect of powder efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

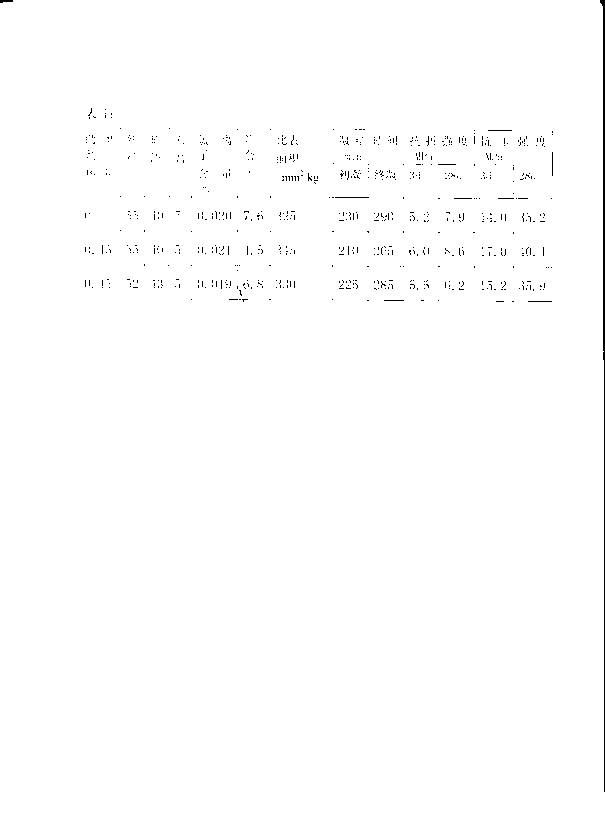

Examples

Embodiment 1

[0016] A powder grinding aid for improving cement performance, which is prepared from the following raw materials according to the weight ratio: 2 parts of triethanolamine, 2 parts of triisopropanolamine, 13 parts of anhydrous sodium chloride, sodium sulfate 25 parts, 10 parts of aluminum sulfate, 25 parts of gypsum, 3 parts of sodium tripolyphosphate, 3 parts of sodium hexametaphosphate, 20 parts of stone powder.

[0017] The powder grinding aid for improving cement performance of the present invention adopts a conventional preparation method, mixes the above-mentioned raw materials according to the formula ratio, and stirs them evenly to obtain the cement grinding aid.

[0018] When the present invention is used, 0.45% is added to the cement mill to save power consumption, properly improve powder efficiency and effectively improve the quality and performance of cement.

Embodiment 2

[0020] A new type of powder cement grinding aid is prepared from the following raw materials in parts by weight: 1 part of triethanolamine, 3 parts of triisopropanolamine, 15 parts of anhydrous calcium chloride, 35 parts of sodium sulfate, 15 parts of aluminum sulfate, 30 parts of gypsum, 5 parts of sodium tripolyphosphate, 5 parts of sodium hexametaphosphate, 30 parts of stone powder.

[0021] When the present invention used, add in the cement mill with the dosage of 0.3%, other is with embodiment 1.

Embodiment 3

[0023] A new type of powder cement grinding aid is prepared from the following raw materials in parts by weight: 2 parts of triethanolamine, 2 parts of triisopropanolamine, 14 parts of anhydrous calcium chloride, 30 parts of sodium sulfate, 15 parts of aluminum sulfate, 28 parts of gypsum, 5 parts of sodium tripolyphosphate, 4 parts of sodium hexametaphosphate, 28 parts of stone powder.

[0024] When the present invention used, add in the cement mill with the dosage of 0.4%, other is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com