Preparation method of lanthanum-doped zinc oxide microsphere with wave absorbing performance

A technology of zinc oxide and microspheres, which is applied in chemical instruments and methods, zinc oxide/zinc hydroxide, and other chemical processes, to achieve wide application prospects, easy control of preparation parameters, and good wave-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

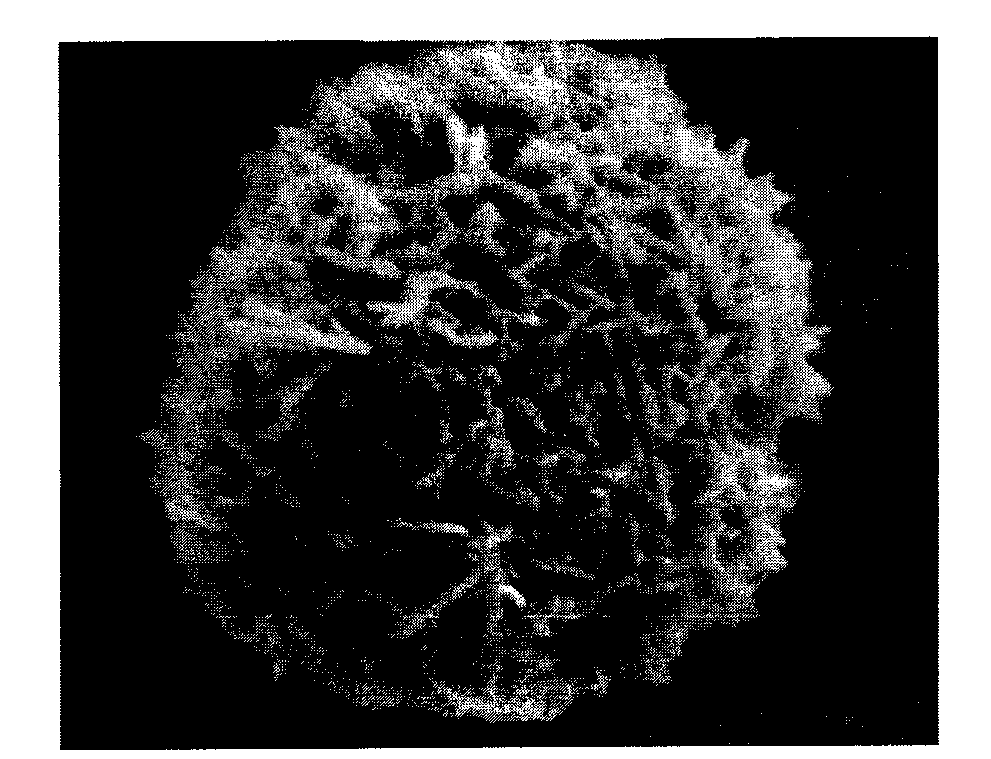

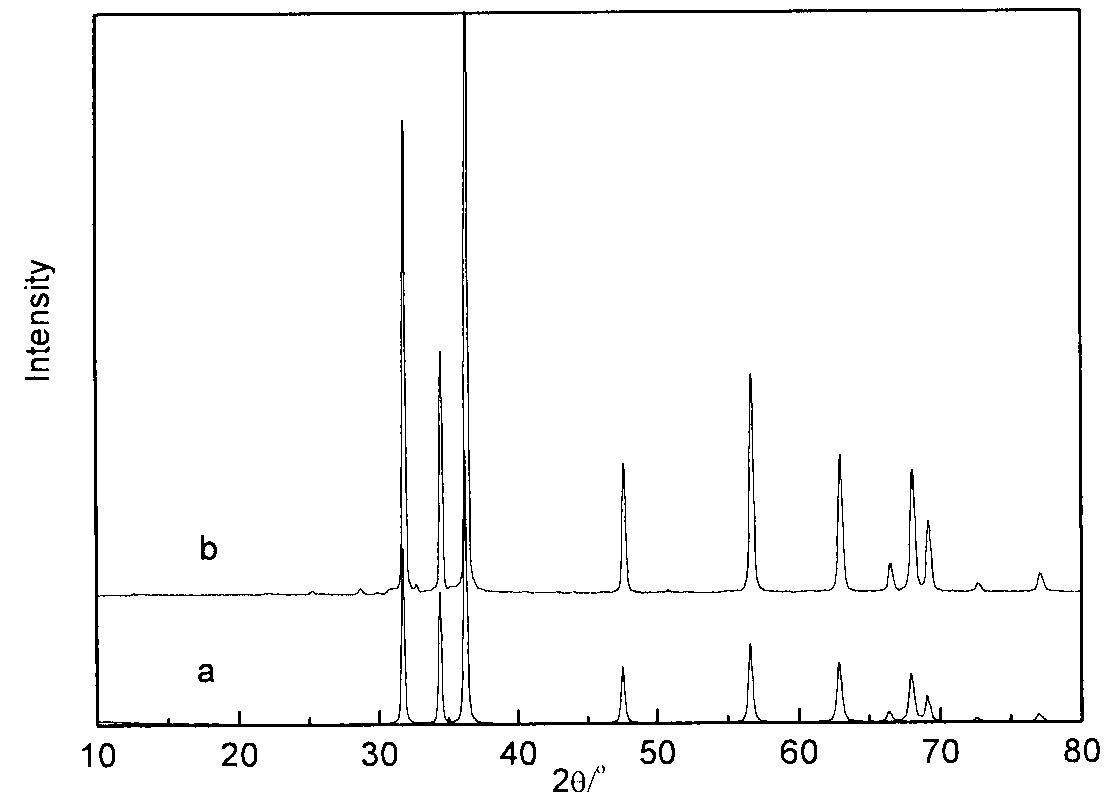

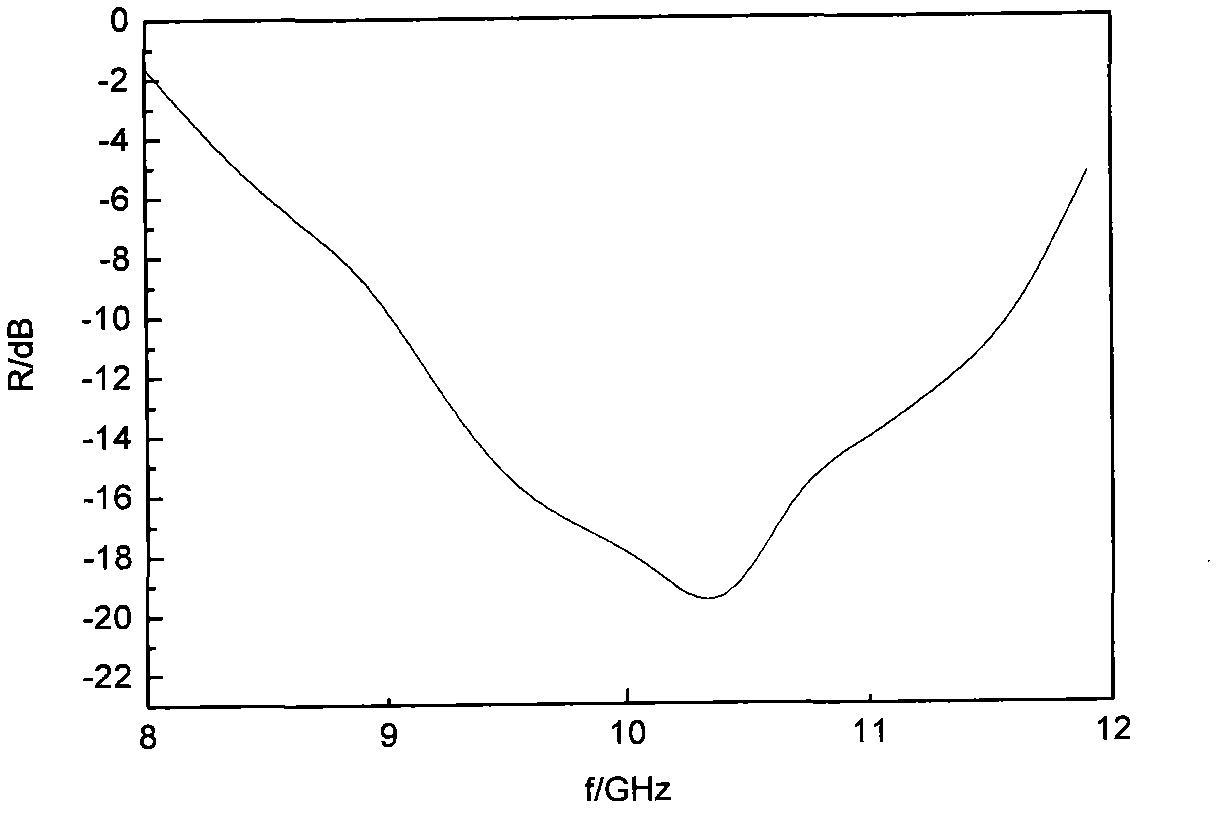

[0018] Attached below Figure 1-3 And specific implementation mode the present invention is described in further detail:

[0019] A preparation method of lanthanum-doped nanostructured zinc oxide microspheres, comprising the following steps: step 1, after mixing equal volumes of 1mol / L zinc acetate and 6mol / L sodium hydroxide solution, adding distilled water 10 times the volume of the solution , ultrasonically vibrate for 10min, then add lanthanum nitrate, the molar ratio of lanthanum to zinc is La / Zn=0.5, and then ultrasonically vibrate for 10min; step 2, inject the resulting suspension into a stainless steel reaction kettle with polytetrafluoroethylene lining Put it in a constant temperature drying box, carry out hydrothermal crystallization at 168°C, and take it out of the reaction kettle after 19 hours of reaction; step 3, after cooling at room temperature, remove the supernatant, and centrifuge the solid powder Separate, wash three times with deionized water, pour the wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com