Method for preparing graphene nano holes

A graphene nanopore, graphene technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., to achieve the effect of improving the success rate of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] In the third step, the graphene nanopores are placed under the protection of protective gas, 1×10 5 - 1×10 -6 Raise the temperature of the sample to 200-1300° C. under the pressure of Pa, and keep it warm for 10-500 minutes, and the pores larger than 5 nanometers shrink to less than 5 nanometers.

[0018] The protective gas is any one of air, argon, nitrogen, hydrogen, methane, acetylene and ethanol.

[0019] Example 1.

[0020] The graphene is suspended on the Cu net of the carrier platform, and then the carrier platform is placed in a transmission electron microscope;

[0021] At room temperature, use a convergent high-energy electron beam to bombard the surface of graphene to obtain nanopores of 10 nanometers;

Embodiment 1

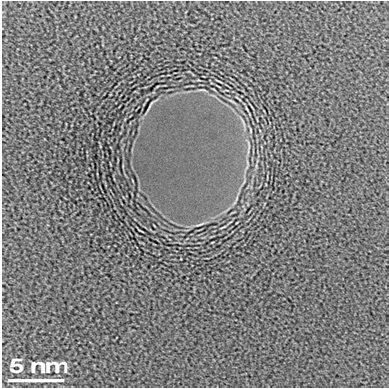

[0023] figure 1 It is a transmission electron micrograph of graphene nanopores with an aperture of 10 nanometers obtained in the initial state;

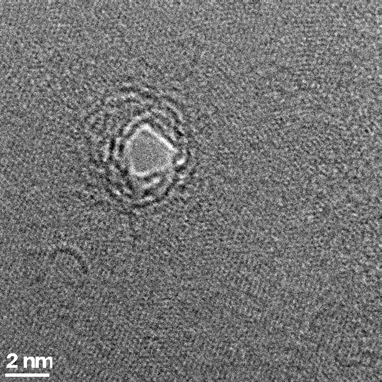

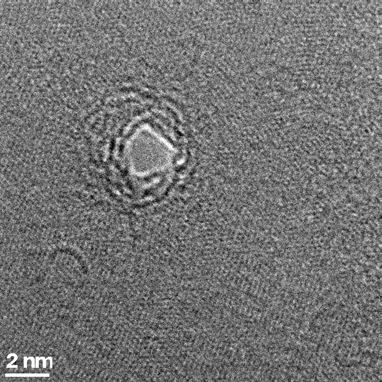

[0024] figure 2 It is a transmission electron microscope image of graphene nanopores with a diameter of 2 nm obtained after heat treatment.

[0025] Example 2.

[0026] The graphene is suspended on the SiN substrate of the carrier platform, and then the carrier platform is placed in the transmission electron microscope;

[0027] Using convergent high-energy electron beams to bombard the surface of graphene at 400°C to obtain nanopores of 6 nanometers;

Embodiment 2

[0029] Example 3.

[0030] Graphene is suspended on a Cu substrate, and then the carrier is placed in a transmission electron microscope;

[0031] 20nm nanopores were obtained by bombarding the surface of graphene with a convergent high-energy electron beam at room temperature;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com